Preparation method and application of large size and shape ratio graphene microsheet

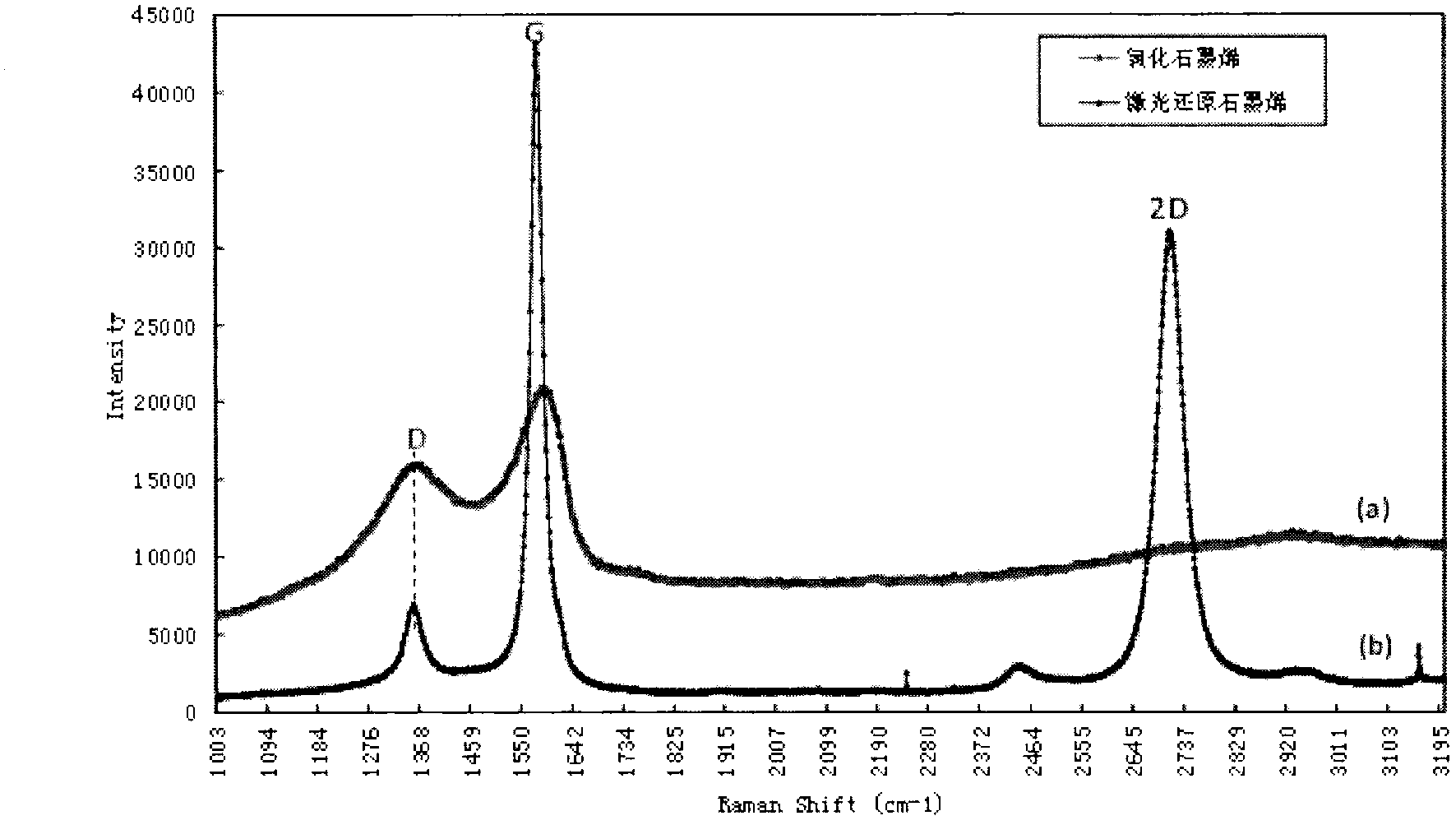

A graphene micro-flake and large-size technology, applied in the direction of graphene, nano-carbon, etc., can solve the problems of precise and controllable atomic layer number of reduced graphene oxide products, inability to obtain graphene micro-flakes, graphene easy to agglomerate, etc. , to achieve the effect of less layers, low cost and large finished product area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

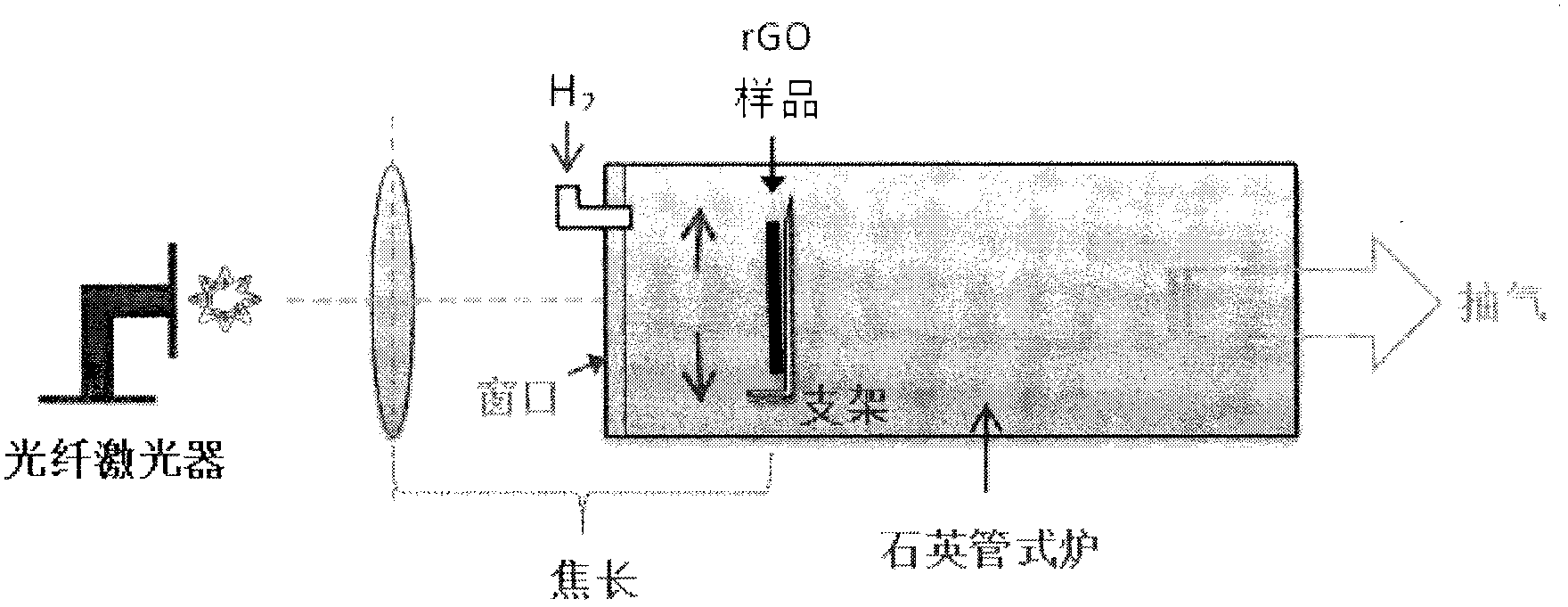

[0024] 1. Glue the glass substrate or independent graphene oxide paper vertically on the support and put it into the quartz tube. The distance between the sample and the window at the end of the quartz tube is about 150mm. Use a mechanical pump and a molecular pump to draw a vacuum until the pressure in the tube drops to 10 -2 Pa; close the exhaust valve, feed some high-purity nitrogen for 2-5 minutes until it fills the furnace tube, then close the nitrogen valve, reopen the exhaust valve, and wait until the pressure in the tube drops to 10 -2 Pa, nitrogen gas is introduced again, and after repeated 2-3 times, the vacuum is continuously pumped for 2-3 hours until the pressure drops to the limit of about 1x10 -4 Pa. Introduce high-purity hydrogen (99.999%) until the relative negative pressure inside the tube rises to -0.05Pa.

[0025] 2. Install the fiber laser, adjust its vertical height and horizontal position, so that the emitted laser beam is just focused on the sample s...

Embodiment 2

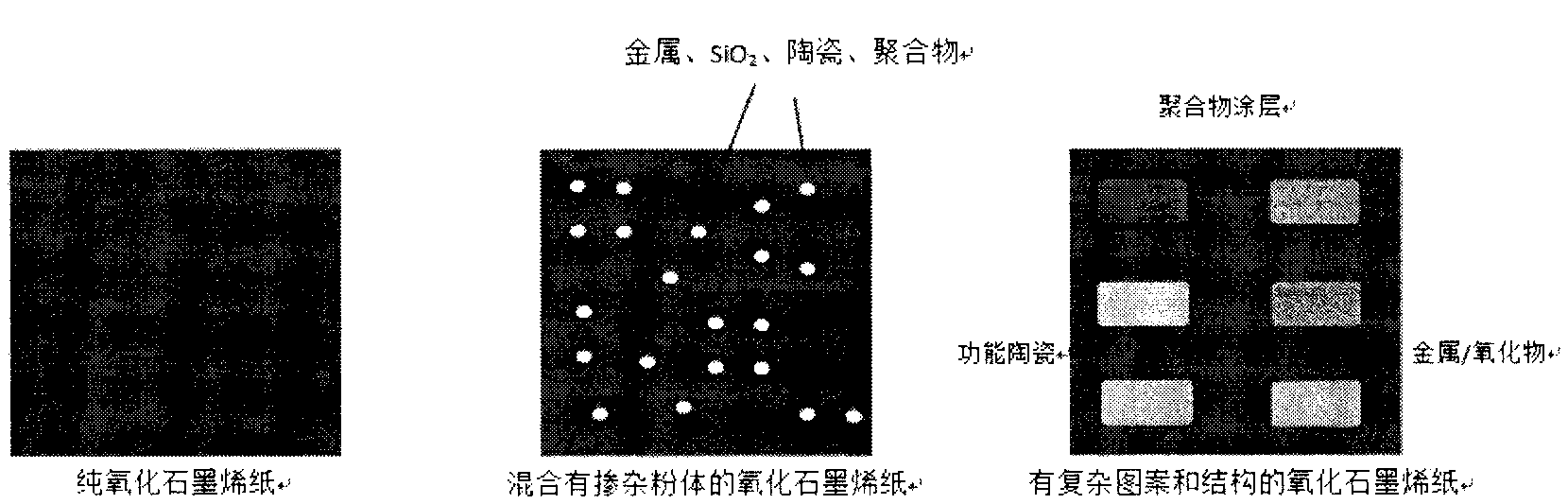

[0029] 1. Will be mixed with impurities (such as SiO 2 Graphene oxide paper (powder, metal particles, carbon nanotubes, etc.) is stuck vertically on the support and put into the quartz tube. The distance between the sample and the window at the end of the quartz tube is about 150mm. Use a mechanical pump and a molecular pump to draw a vacuum until the pressure in the tube drops to 10 -2 Pa; close the exhaust valve, feed some high-purity nitrogen for 2-5 minutes until it fills the furnace tube, then close the nitrogen valve, reopen the exhaust valve, and wait until the pressure in the tube drops to 10 -2 Pa, nitrogen gas is introduced again, and after repeated 2-3 times, the vacuum is continuously pumped for 2-3 hours until the pressure drops to the limit of about 1x10 -4 Pa. Introduce high-purity hydrogen (99.999%) until the relative negative pressure inside the tube rises to -0.05Pa.

[0030] 2. Install the fiber laser, adjust its vertical height and horizontal position, ...

Embodiment 3

[0034] 1. A graphene oxide paper containing patterned and complex structures (such as polymer coatings) is glued vertically on a support and placed in a quartz tube. The distance between the sample and the window at the end of the quartz tube is about 150mm. Use a mechanical pump and a molecular pump to draw a vacuum until the pressure in the tube drops to 10 -2 Pa; close the exhaust valve, feed some high-purity nitrogen for 2-5 minutes until it fills the furnace tube, then close the nitrogen valve, reopen the exhaust valve, and wait until the pressure in the tube drops to 10 -2 Pa, nitrogen gas is introduced again, and after repeated 2-3 times, the vacuum is continuously pumped for 2-3 hours until the pressure drops to the limit of about 1x10 -4 Pa. Introduce high-purity hydrogen (99.999%) until the relative negative pressure inside the tube rises to -0.05Pa.

[0035] 2. Install the fiber laser, adjust its vertical height and horizontal position, so that the emitted laser ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com