Method for preparing surface-modified hydrotalcite compound through adopting brucite

A hydrotalcite-type, surface modification technology, applied in the direction of alumina/aluminum hydroxide, etc., can solve the problems such as hindering the large-scale application of hydrotalcite, high preparation cost of hydrotalcite, increasing the cost of hydrotalcite, etc. The effect of saving production time and simplifying the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

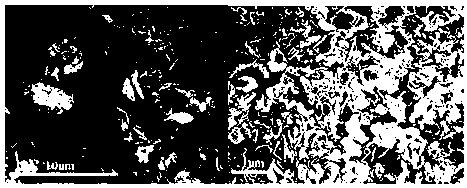

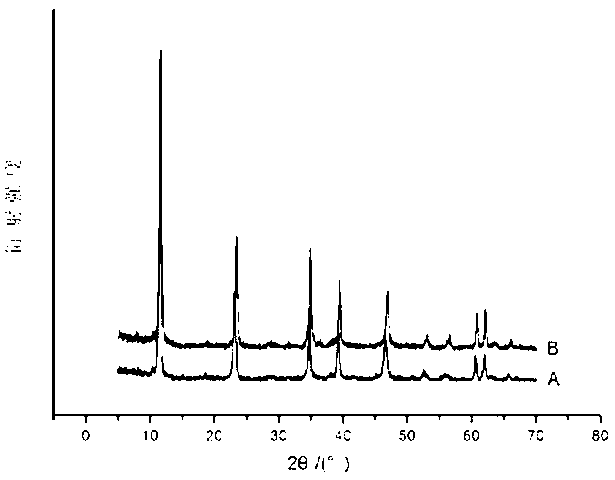

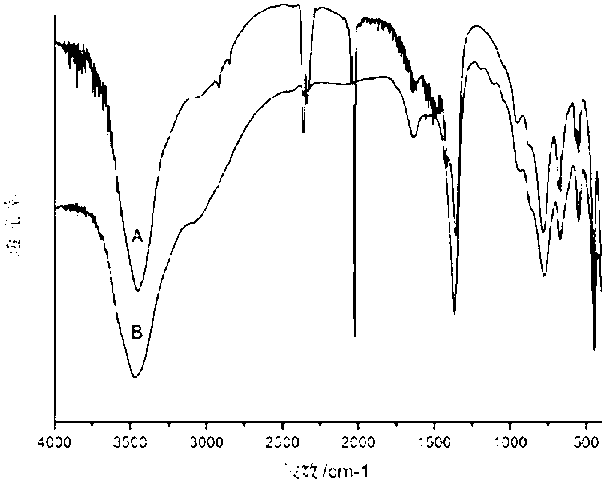

Image

Examples

Embodiment 1

[0025] Weigh 2.48g of brucite, 3.28g of sodium metaaluminate, 4.42g of sodium carbonate, 0.07g of Span-80 and a certain amount of water in a hydrothermal reaction kettle, keep the temperature at 120°C for 16h under full stirring, and after cooling Suction filtration, washing, and drying at 90°C for 12 hours to obtain surface-modified magnesium aluminum hydrotalcite. After testing, the degree of activation is 1.

[0026] Contrast group: Weigh 2.48g brucite, 3.28g sodium metaaluminate, 4.42g sodium carbonate and a certain amount of water in a hydrothermal reaction kettle, under full stirring, keep the temperature at 120°C for 16h, suction filter and wash after cooling , and dried at 90°C for 12 hours to obtain surface-modified magnesium aluminum hydrotalcite. After testing, the activation degree was 0.

[0027] The degree of activation is one of the indicators for measuring the hydrophobicity of the surface of inorganic substances after modification, and is used to judge the d...

Embodiment 2

[0030] Weigh 5.54g of brucite, 5.63g of aluminum nitrate, 0.84g of sodium bicarbonate, 4ml of ammonia water, 0.07g of monopropylene glycol stearate, and a certain amount of water in a hydrothermal reaction kettle. After cooling for 1 hour, filter with suction, wash, and dry at 90°C for 12 hours to obtain surface-modified magnesium aluminum hydrotalcite. After testing, the degree of activation is 0.9.

Embodiment 3

[0032] Weigh 3.69g brucite, 1.02g alumina, 0.99g zinc hydroxide, 0.90g urea, 1.12g potassium hydroxide, 0.30g titanate coupling agent KR-201 and a certain amount of water in the hydrothermal reaction kettle , under full stirring, at a constant temperature of 180°C for 4 hours, after cooling, suction filtration, washing, and drying at 90°C for 12 hours, to obtain surface-modified magnesium-aluminum-zinc hydrotalcite. After testing, the degree of activation is 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com