Synthesis method of bis-sulfydryl chelating agent for processing heavy metal complex wastewater

A double-mercapto-type, synthetic method technology, applied in chemical instruments and methods, water/sludge/sewage treatment, flocculation/sedimentation water/sewage treatment, etc., can solve the problems such as the treatment effect is not obvious, and the synthesis method is simple and easy High efficiency, high yield and fast precipitation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

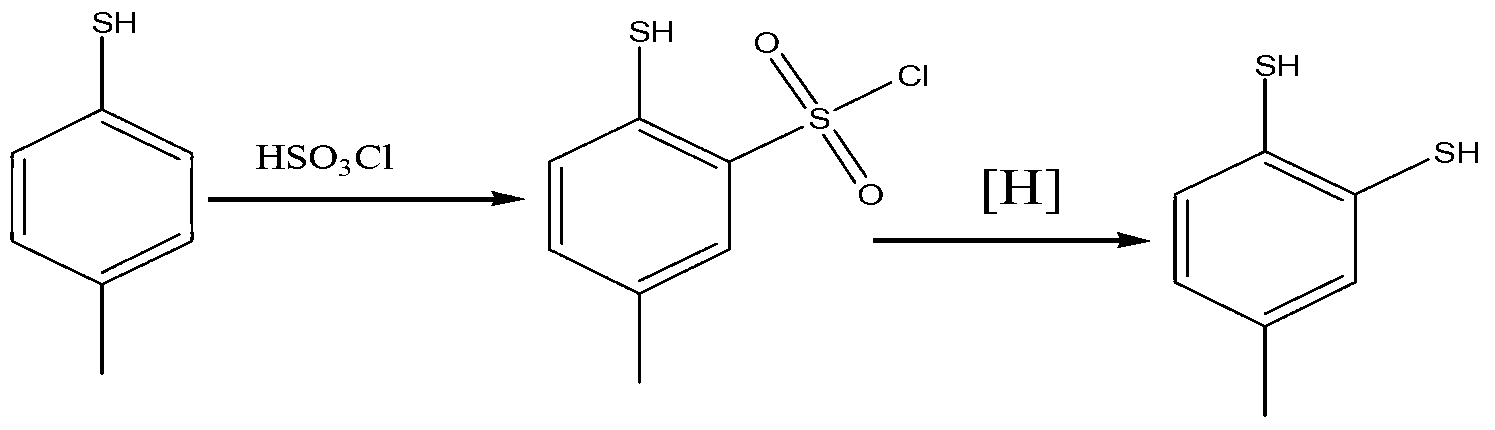

Method used

Image

Examples

Embodiment 1

[0017] Example 1: In 25g of 1,2-dichloroethane, add 10.0g of p-methylthiophenol, 11.3g of chlorosulfonic acid, react at 60°C for 4 hours, add 20mL of water, separate the liquid, and wash with water until medium property, dried and evaporated to dryness to obtain 16.8 g of yellow solid 5-methyl-2-mercapto-benzenesulfonyl chloride with a purity of 95%. Add 17.0g of 5-methyl-2-mercapto-benzenesulfonyl chloride and 21.4g of zinc powder into 20mL of water at 0°C, stir for 30min, add 59.0g of concentrated hydrochloric acid, heat to reflux for 2h, and steam distill to obtain white 4 -Methyl-2-mercaptothiophenol 11.8g, melting point 25-28°C, yield 98%.

Embodiment 2

[0018] Example 2: In 25g of chloroform, add 10.0g of p-methylthiophenol, 11.3g of chlorosulfonic acid, react for 3 hours at 70°C, add 20mL of water, separate the liquids, wash with water until neutral, dry, and evaporate to dryness , to obtain 17.0 g of yellow solid 5-methyl-2-mercapto-benzenesulfonyl chloride with a purity of 98%. Add 17.0g of 5-methyl-2-mercapto-benzenesulfonyl chloride and 21.9g of iron powder into 20mL of water at 0°C, stir for 30min, add 59.0g of concentrated hydrochloric acid, heat to reflux for 2.5h, and steam distill to obtain white 11.8g of 4-methyl-2-mercaptothiophenol, melting point 25-28°C, yield 98%.

Embodiment 3

[0019] Example 3: Add 10.0 g of p-methylthiophenol and 13.8 g of chlorosulfonic acid to 25 g of dichloromethane, react for 3.5 hours at 60° C., add 20 mL of water, separate the liquids, wash with water until neutral, and dry. Evaporate to dryness to obtain 16.5 g of yellow solid 5-methyl-2-mercapto-benzenesulfonyl chloride with a purity of 96%. Add 17.0 g of 5-methyl-2-mercapto-benzenesulfonyl chloride and 21.4 g of zinc powder into 20 mL of water at 0°C, stir for 30 min, add 59.0 g of concentrated hydrochloric acid, heat to reflux for 2 h, and steam distill to obtain white 4 -Methyl-2-mercaptothiophenol 11.8g, melting point 25-28°C, yield 98%.

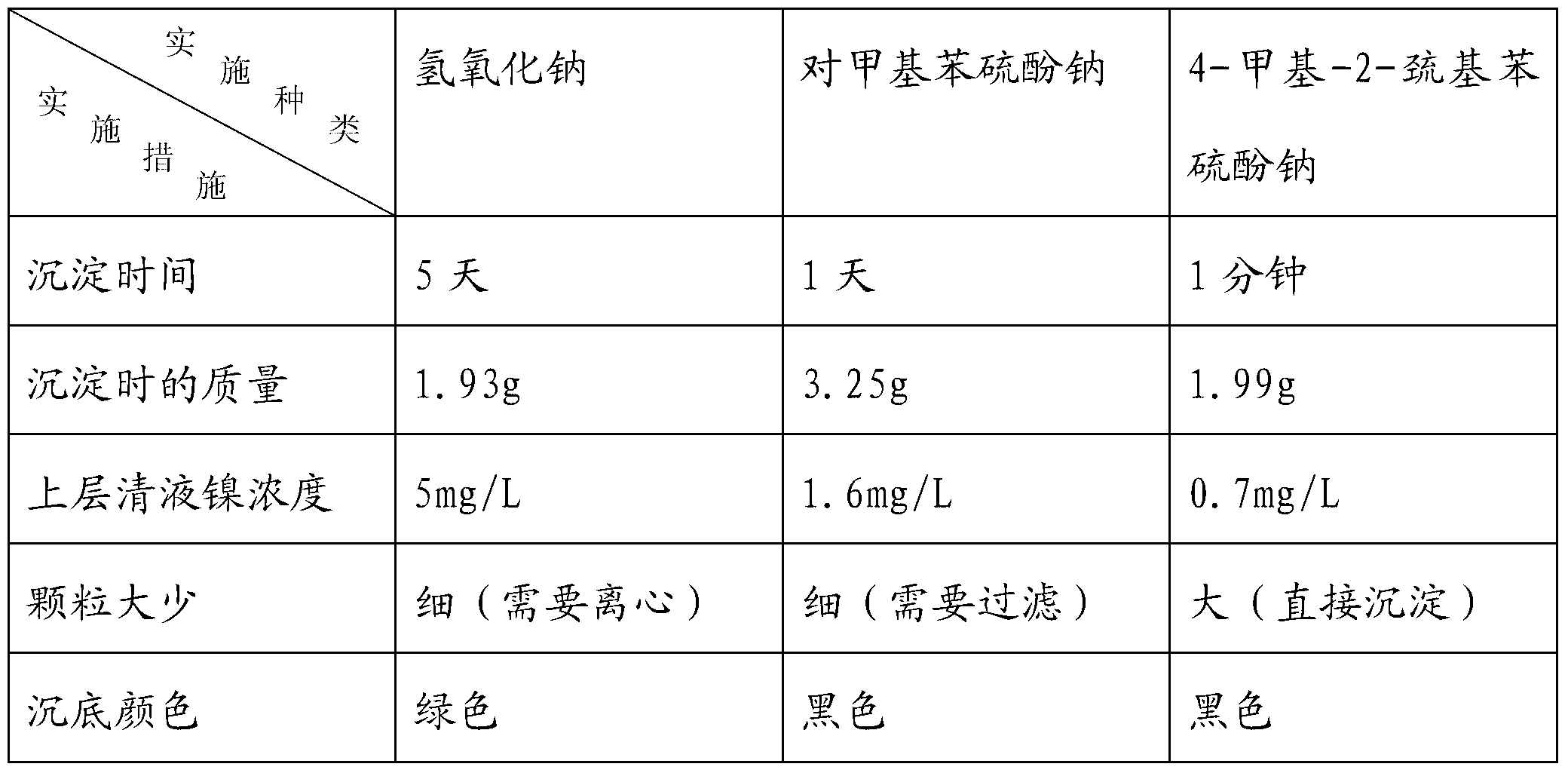

[0020] The chelating agent obtained above is used for heavy metal complex wastewater treatment, and the treatment method is as follows:

[0021] Add the chelating agent p-methylthiophenol or 4-methyl-2-mercaptothiophenol to sodium hydroxide with an equal amount of substance, heat and melt until it turns into a yellow sodium salt. Ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com