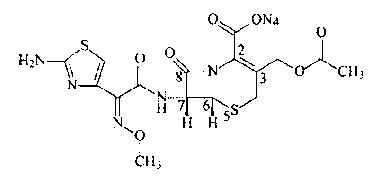

Crystallization method for cefotaxime sodium

A kind of technology of cefotaxime sodium and cefotaxime acid, which is applied in the crystallization field of cefotaxime sodium

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Take 20g of cefotaxime acid and 4.43g of sodium bicarbonate, add them into 150ml of water-containing solvent system (the water-containing solvent system is composed of 15ml of water and 135ml of methanol), control the temperature at -10°C, and stir to dissolve. Add 0.2 g of activated carbon, decolorize for 30 minutes, and filter; wash the filtered carbon layer with methanol, and combine the filtrate and washing liquid. Control the temperature at -10°C, add 100ml of acetone (crystal precipitation agent) dropwise within 60 minutes, add 0.3g of seed crystals, and grow the crystal for 60 minutes; within 100 minutes, add dropwise 600ml of acetone (crystal precipitation agent) to crystallize; The obtained crystals are washed; dried at 40° C. and a vacuum of 0.093 MPa until the moisture content and residual solubility are qualified.

[0024] Its yield: 95.0%; content: 96.7%; single largest impurity: 0.3%; total impurity: 1.2%; solution color: 2+; clarity 0.25-.

Embodiment 2

[0026] Take 20g of cefotaxime acid and 4.32g of sodium acetate, add it to 100ml of water-containing solvent system (the water-containing solvent system is composed of 20ml of water and 80ml of ethanol), control the temperature at 0°C, and stir to dissolve. Add 0.2 g of activated carbon, decolorize for 30 minutes, and filter; wash the filtered carbon layer with ethanol, and combine the filtrate and washing liquid. Control the temperature at 0°C, add 80ml of butyl acetate dropwise within 100min, add 0.25g of seed crystal, and grow the crystal for 50min; within 250min, add 600ml of acetone and butyl acetate (v / v=1 / 1) dropwise, filter, and use Wash the crystals obtained by filtration; dry at 35° C. and a vacuum of 0.095 MPa until the water content and residual solubility are qualified.

[0027] Its yield: 95.6%, content: 96.2%, single largest impurity: 0.3%, sum of impurities: 1.3%, solution color: 2+, clarity 0.25-.

Embodiment 3

[0029] Take 20g of cefotaxime acid and 8.76g of sodium isooctanoate, add it to 120ml of water-containing solvent system (the water-containing solvent system is composed of 10ml of water and 110ml of isopropanol), control the temperature at 5°C, and stir to dissolve. Add 0.2 g of activated carbon, decolorize for 30 minutes, and filter; wash the filtered carbon layer with a mixture of water and isopropanol, and combine the filtrate and washing liquid. Control the temperature at 5°C, within 200 minutes, add 90ml of isopropanol dropwise, add 0.4g of seed crystals, and grow the crystals for 40 minutes; within 300 minutes, add 200ml of butyl acetate dropwise, filter, and wash the filtered crystals with butyl acetate; Dry at 38°C and vacuum degree of 0.095MPa until the water content and residual solubility are qualified.

[0030] Its yield: 95.1%, content: 96.7%, single largest impurity: 0.3%, sum of impurities: 1.1%, solution color: 2+, clarity 0.25-.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com