Microfluidics-based initiating explosive synthesis system and method thereof

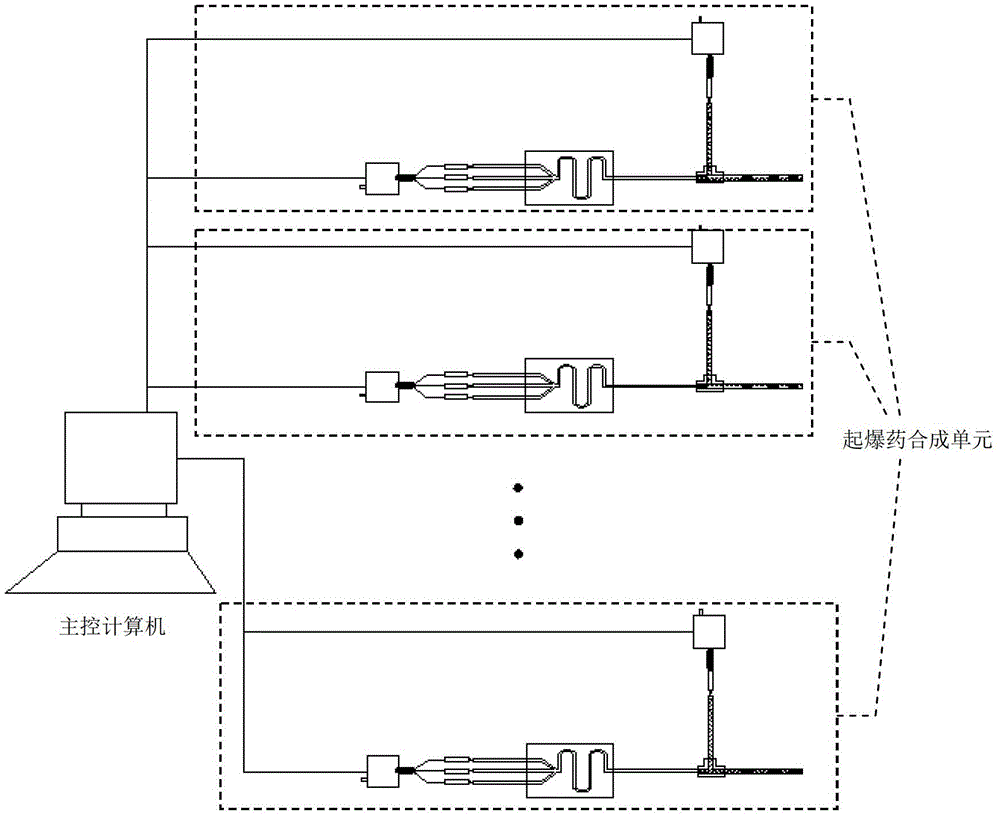

A technology of microfluidic technology and synthesis method, which is applied in the field of pyrotechnics and detonating devices, which can solve the problems of large waste of raw materials, achieve low energy and material consumption, ensure consistency, and achieve good economic benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

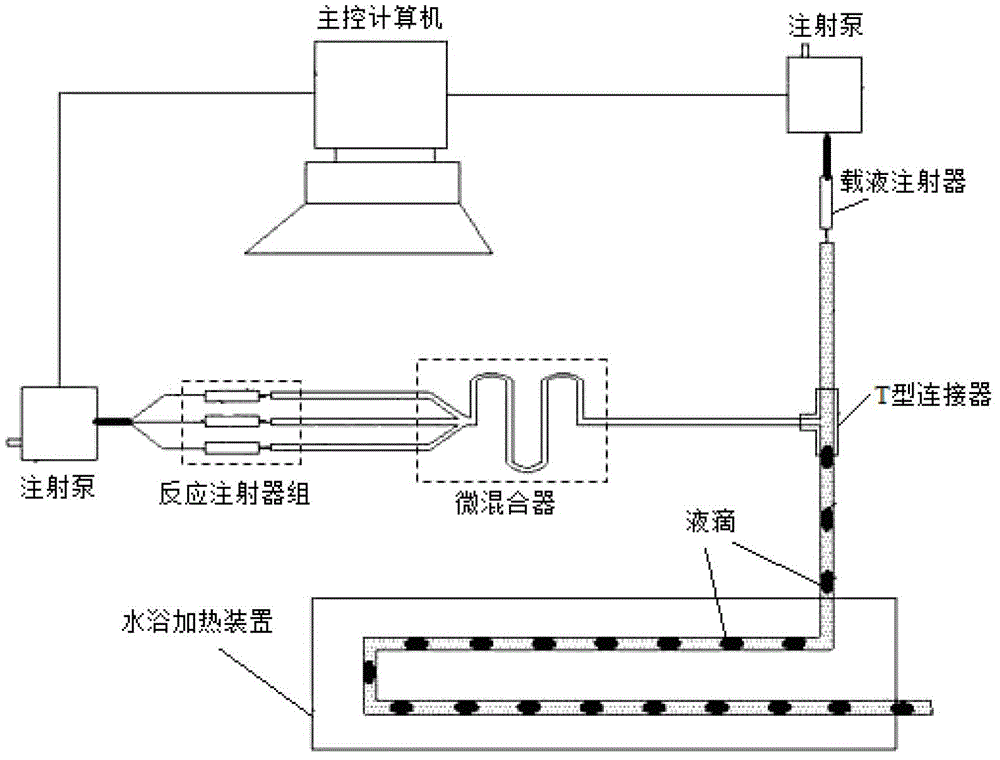

[0027] The present invention is based on the method for synthesizing primer of microfluidic technology, comprising the following steps:

[0028] Step 1, preparing each reaction solution and crystal form control agent of the target primary explosive, adding different reaction solutions to different syringes in the reaction syringe group, and adding the crystal form control agent to another syringe of the reaction syringe group separately;

[0029] Refer to "Primer Chemistry and Technology" of National Defense Industry Press to determine each part of the reaction liquid and crystal form control agent of the target primer;

[0030] Step 2, adding the carrier liquid into the carrier liquid syringe, the carrier liquid is liquid paraffin or tetradecane;

[0031] Step 3, according to the reaction conditions of the target primary explosive, set the flow rate parameters of the two syringe pumps and the water bath temperature of the water bath heating device on the main control computer...

Embodiment 1

[0036] Embodiment 1: the preparation of crystalline lead trinitroresorcinol

[0037] Step 1, prepare two parts of reaction solutions of lead trinitroresorcinol crystallization target primer: 0.1M lead nitrate aqueous solution and 0.05M trinitroresorcinol sodium solution, mix 0.1M lead nitrate aqueous solution and 0.05M trinitroresorcinol sodium solution Add the sodium nitroresorcinol solution into different syringes in the reaction syringe group respectively;

[0038]Step 2, adding the carrier liquid paraffin into the carrier liquid syringe;

[0039] Step 3, according to the reaction conditions of the target primary explosive, set the flow rate parameters of the two syringe pumps and the water bath temperature of the water bath heating device on the main control computer: set the liquid flow rate of the syringe pump connected to the reaction syringe group to 0.3mL / min , set the liquid flow rate of the syringe pump connected to the carrier liquid syringe group to 1mL / min, and ...

Embodiment 2

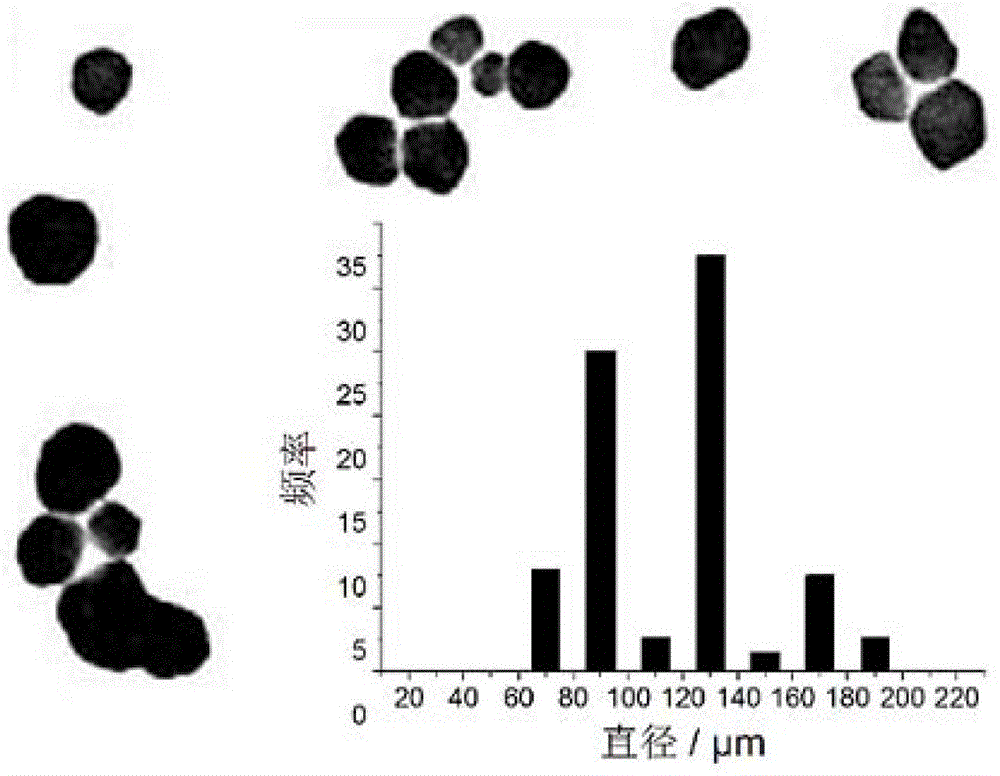

[0044] Embodiment 2: Preparation of modified crystalline lead trinitroresorcinol

[0045] Step 1, prepare two parts of reaction liquids of target primer modified crystalline lead trinitroresorcinol: 0.05M lead nitrate aqueous solution and 0.05M trinitroresorcinol magnesium solution, mix 0.05M lead nitrate aqueous solution and 0.05 M trinitroresorcinol magnesium solution was added to different syringes in the reaction syringe group, and the crystal form control agent was configured 3 × 10 -5 mM carboxymethylcellulose and add it separately to another syringe of the reaction syringe set;

[0046] Step 2, adding the carrier liquid paraffin into the carrier liquid syringe;

[0047] Step 3, according to the reaction conditions of the target primary explosive, set the flow rate parameters of the two syringe pumps and the water bath temperature of the water bath heating device on the main control computer: set the liquid flow rate of the syringe pump connected to the reaction syringe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com