Jet type membrane reactor and method for preparing methylaniline by continuous catalytic hydrogenation

A technology of methyl aniline and membrane reactor, applied in the field of reactors, can solve the problems of increasing large power consumption, affecting product quality, increasing product consumption, etc., achieving the effects of separation efficiency, energy saving, equipment investment saving, and sufficient reaction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

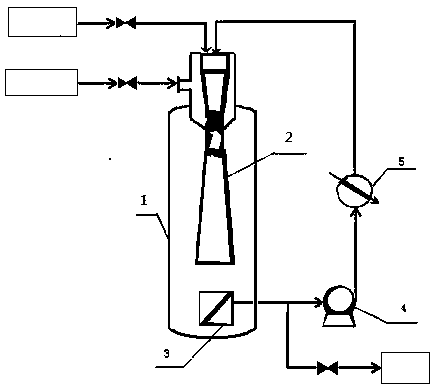

[0023] Example 1: Mononitrotoluene is preheated to 100°C and then pumped into the jet mixer. Hydrogen and mononitrotoluene are fully mixed in the jet mixer and then enter the reactor body, under the action of the catalyst-Raney nickel. Reduction reaction, the reacted material flows through the membrane module, the membrane in the membrane module is a flat ceramic membrane, the catalyst is trapped in the reactor body for recycling, part of the permeate is extracted as a crude product, and part of the permeate passes through the heat exchanger The heat is exchanged and circulated to the jet mixer by the circulation pump. After analysis and testing, the conversion rate of the reaction was 95%.

Embodiment 2

[0024] Example 2: Mononitrotoluene is preheated to 110°C and then pumped into the jet mixer. Hydrogen and mononitrotoluene are fully mixed in the jet mixer and then enter the reactor body for reduction under the action of the catalyst-palladium carbon reaction, the reacted material flows through the membrane module, the membrane in the membrane module is a tubular mullite membrane, the catalyst is trapped in the reactor body for recycling, part of the permeate is extracted as a crude product, and part of the permeate is processed through heat exchange The heat exchanger is exchanged and circulated to the jet mixer by the circulation pump. After analysis and testing, the conversion rate of the reaction was 96%.

Embodiment 3

[0025] Example 3: Mononitrotoluene is preheated to 120°C and then pumped into the jet mixer. Hydrogen and mononitrotoluene are fully mixed in the jet mixer and then enter the reactor body. The reduction reaction is carried out under the action of the reaction, and the reacted material flows through the membrane module. The membrane in the membrane module is a tubular hollow fiber membrane, and the catalyst is trapped in the reactor body for recycling. The liquid is heat-exchanged through the heat exchanger and circulated to the jet mixer by the circulation pump. After analytical testing, the conversion rate of the reaction was 98%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com