Novel nano-fluid and its preparation method and application thereof

A nanofluid, a new type of technology, applied in chemical instruments and methods, fibrous fillers, dyed low-molecular-weight organic compounds, etc., can solve the problems of weak physical affinity, suboptimal effect, difficult application of direct modification, etc. Achieving the effect of simple and easy preparation method and improved processing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Embodiment 1: Preparation of novel nanofluid

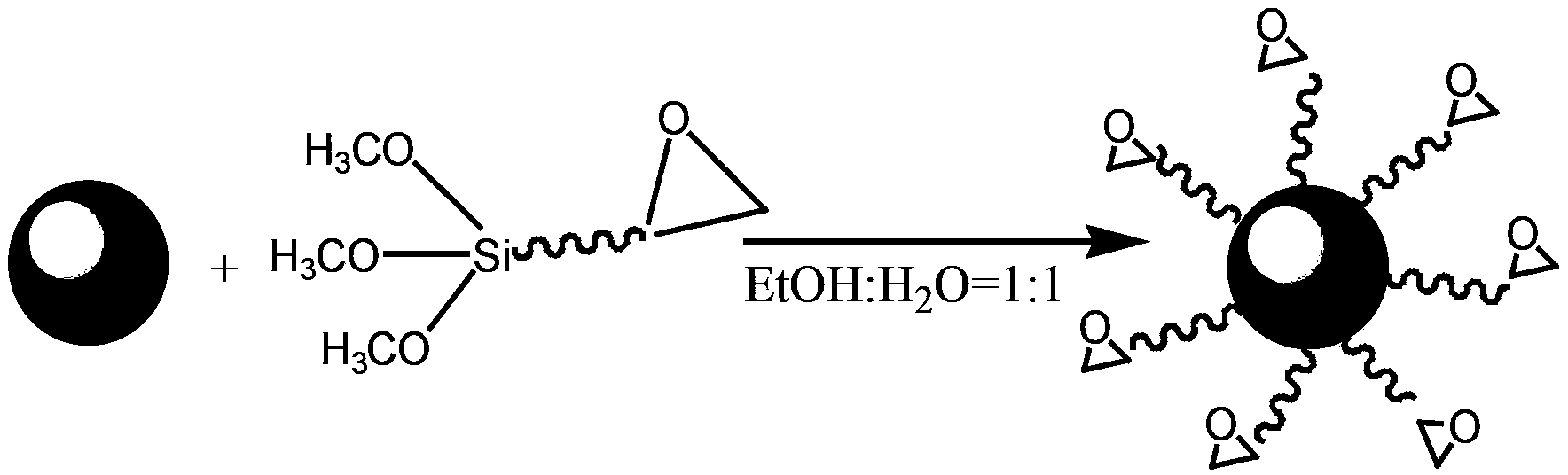

[0049] (1) Weigh 1.67g of 30wt% silica aqueous solution (purchased from Sigma-Aldrich) with an average particle size of 7nm and dilute it in 75ml of water (use sodium hydroxide to adjust the pH of the solution to 12), sonicate for 1h; Dissolve 0.59g of γ-glycidyl ether propoxytrimethoxysilane coupling agent (purchased from Aladdin Reagent Company) in 40ml of ethanol, then pour it into the above-mentioned sonicated silica solution, and stir at 70°C for reaction , after 6h, the reaction is complete, and the reaction solution of nano-silica / epoxy coupling agent is obtained. For the reaction mechanism, see figure 1 .

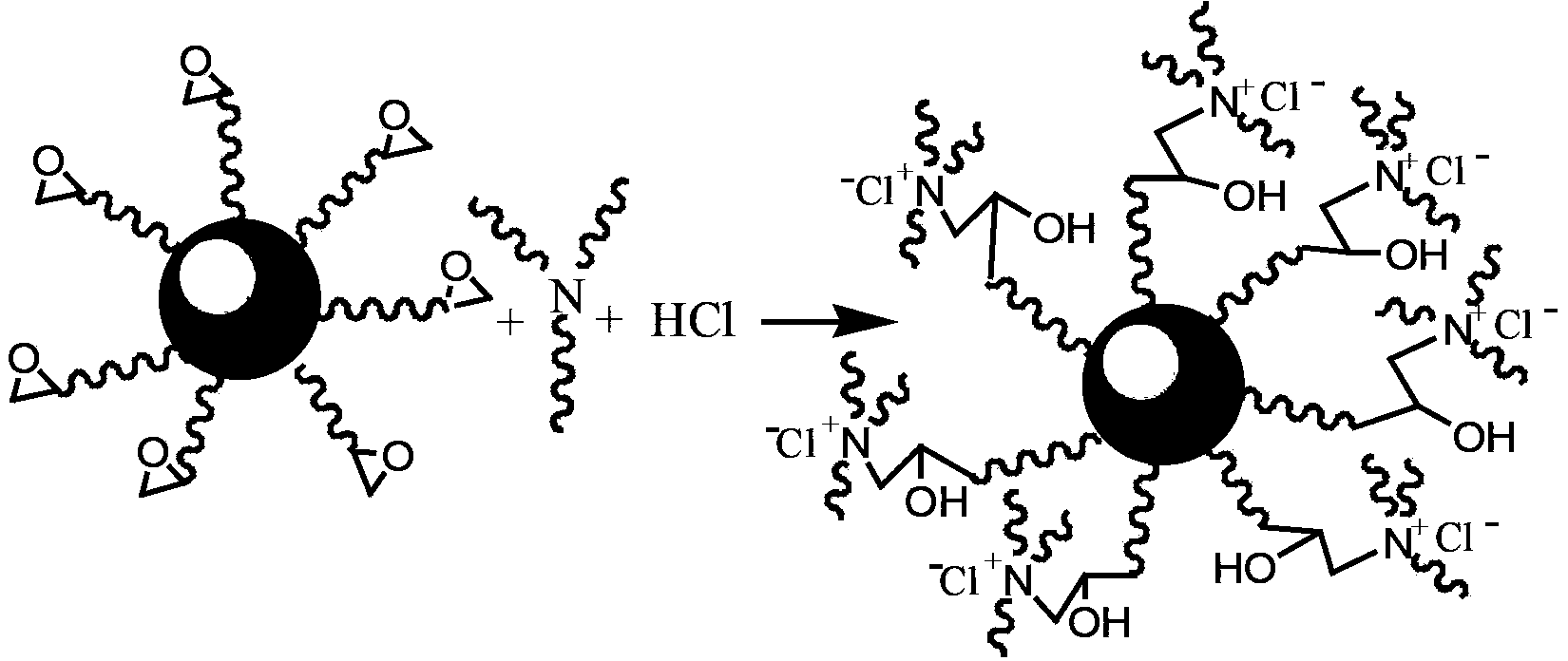

[0050] (2) Weigh and add 0.51g of tri-n-butylamine and 0.27g of concentrated hydrochloric acid with a concentration of 36.5wt% to the nano-silica / epoxy coupling agent reaction solution in step (1), stir and react at a constant temperature of 70°C , after 24 hours of reaction, the reaction solution of nano-silic...

Embodiment 2

[0053] Embodiment 2: Preparation of novel nanofluid

[0054] (1) Weigh 1.67g of 30wt% silica aqueous solution (purchased from Sigma-Aldrich) with an average particle size of 7nm and dilute it in 75ml of water (use sodium hydroxide to adjust the pH of the solution to 12), sonicate for 1h; Dissolve 0.59g of γ-glycidyl ether propoxytrimethoxysilane coupling agent (purchased from Aladdin Reagent Company) in 40ml of ethanol, then pour it into the above-mentioned sonicated silica solution, and stir at 70°C for reaction , after 6h, the reaction is complete, and the reaction solution of nano-silica / epoxy coupling agent is obtained. For the reaction mechanism, see figure 1 .

[0055] (2) Weigh and add 0.51g of tri-n-butylamine and 0.27g of concentrated hydrochloric acid with a concentration of 36.5wt% to the nano-silica / epoxy coupling agent reaction solution in step (1), stir and react at a constant temperature of 70°C , after 24 hours of reaction, the reaction solution of nano-silic...

Embodiment 3

[0057] Embodiment 3: Preparation of novel nanofluid

[0058] (1) Weigh 1.67g of a 30% silica solution with an average particle size of 7nm and dilute it in 5ml of water, ultrasonicate for 1h, and add 5.0g of γ-glycidyl ether propoxymethoxydiethoxysilane coupling agent Dissolve it in 40ml of ethanol, then pour it into the sonicated silicon dioxide aqueous solution, stir and react at a constant temperature at 80°C, and the reaction is complete after 4 hours to obtain a nanometer silicon dioxide / epoxy coupling agent reaction solution.

[0059] (2) Weigh and add 2.55g of tri-n-butylamine and 1.35g of concentrated hydrochloric acid with a mass concentration of 36.5% to the nano-silica / epoxy coupling agent reaction solution in step (1), stir and react at a constant temperature of 80°C , after reacting for 1 hour, the reaction liquid of nano-silica / ammonium salt organic ions was obtained.

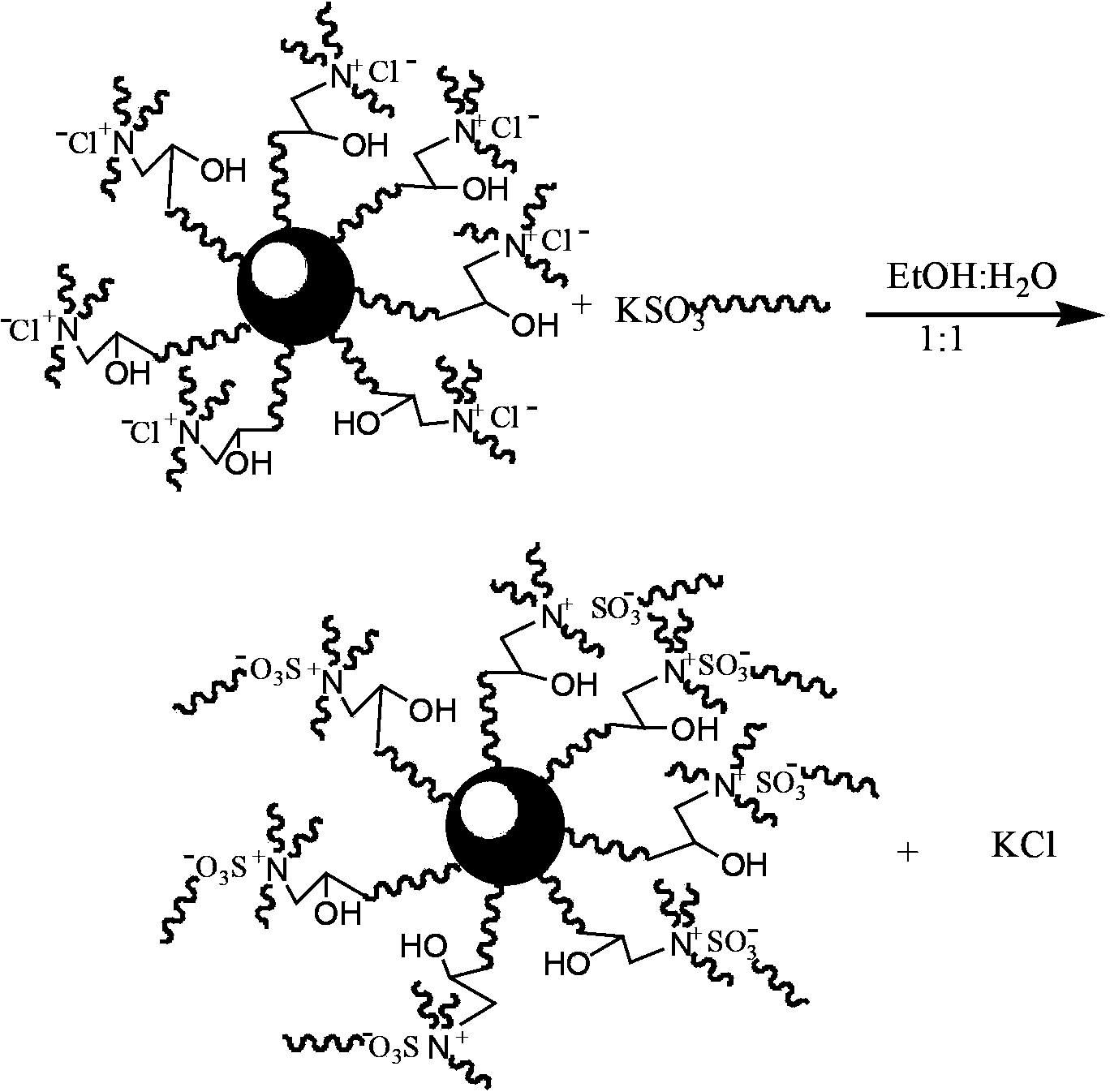

[0060] (3) Add 2.04g of C 9 h 19 -(C 6 h 4 )-(OCH 2 CH 2 ) 10 -O(CH 2 ) 3 SO 3 – K...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com