Modified activated carbon demercuration adsorbent and preparation method thereof

A technology of activated carbon and adsorbent, which is applied in the field of mercury removal from coal-fired flue gas. It can solve the problems of high cost, poor economy, and low efficiency of activated carbon, improve the apparent structure and pore structure, reduce operating costs, and have strong environmental adaptability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

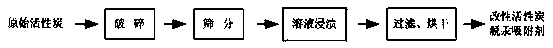

Method used

Image

Examples

Embodiment 1

[0017] The crushed and dried coal-based activated carbon is sieved, and the powder of about 200 meshes is selected for use; 2g of analytically pure ammonium chloride NH is weighed 4 Cl is placed in a beaker, and 200ml of deionized water is added to the beaker, stirred evenly with a magnetic stirrer, and ammonium chloride NH with a mass fraction of 1% is prepared. 4 Cl solution; weigh 10g of 200 mesh sieved activated carbon powder, put it into the prepared 1% ammonium chloride NH 4 In the Cl solution, use a magnetic stirrer to stir for 12 hours; filter the waste liquid, dry the filtered solid matter in a 45°C oven, and grind it to powder, that is, 1% ammonium chloride NH 4 Cl solution modified coal-based activated carbon adsorbent for mercury removal.

Embodiment 2

[0019] Crushed and dried cylindrical coal-based activated carbon, sieved, and selected powder of about 200 meshes for use; weighed 2g of analytically pure ammonium bromide NH 4 Br was placed in a beaker, and 200ml of deionized water was added to the beaker, stirred evenly with a magnetic stirrer, and ammonium bromide NH with a mass fraction of 1% was prepared. 4 Br solution; weigh 10g of 200 mesh sieved activated carbon powder, put into the prepared 1% ammonium bromide NH 4 In the Br solution, use a magnetic stirrer to stir for 12 hours; filter off the waste liquid, dry the filtered solid matter in an oven at 45°C, and grind it to powder to obtain 1% ammonium bromide NH 4 Br solution modified coal-based activated carbon adsorbent for mercury removal.

Embodiment 3

[0021] Select the 1%NH prepared in Example 1 for use 4 Cl-modified activated carbon adsorbent for mercury removal, and its adsorption performance was verified on a fixed-bed adsorption performance test device. The fixed bed test device consists of a simulated flue gas generation system, a fixed bed reactor, a mercury detector, etc., N 2 Atmosphere, the total gas flow rate is 2L / min. Mercury vapor is generated by a mercury permeation tube (manufactured by VICI Metronics, USA) placed in a U-shaped high borosilicate glass tube. The generated mercury vapor is carried out by using high-purity nitrogen as a carrier gas, and the flow rate of the carrier gas is 150ml / min. The concentration of mercury in the flue gas was determined using a VM-3000 online mercury analyzer (manufactured by Mercury Instrument, Germany). The mercury vapor concentration at the inlet of the fixed bed was 35.5 / m during the test 3 , the amount of original activated carbon and modified activated carbon is 50...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com