One-kettle continuously step-by-step synthesized calcium zinc composite stabilizer

A calcium-zinc composite and segmented synthesis technology, which is applied in the field of plastic additives, can solve problems such as unstable quality, poor product stability, and high labor intensity, and achieve the effects of strong product controllability, no dust flying, and labor saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

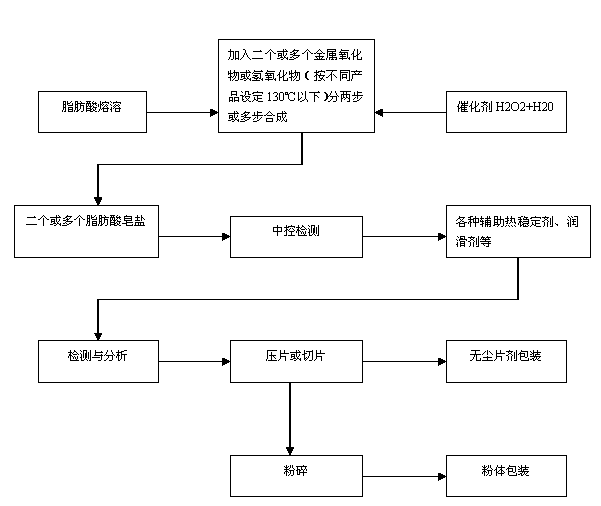

Method used

Image

Examples

Embodiment 1

[0012] Embodiment 1: Calcium-zinc composite stabilizer applied to PVC pipes

[0013] The preparation process of the stabilizer: 25 parts of fatty acid, 12 parts of calcium hydroxide, 10 parts of zinc oxide, 2.7 parts of hydrogen peroxide and glacial acetic acid mixed solution (molar ratio 5:1~8:1) were weighed respectively by molar parts, and the fatty acid Put it into the reaction kettle and heat it to dissolve (the melting temperature at this time is controlled between 60°C-80°C), and then add zinc oxide under the conditions of stirring speed of 80-150 rpm and reaction temperature of 110°C-130°C. And control the adding speed of the mixed solution of catalyst hydrogen peroxide and glacial acetic acid, add calcium hydroxide after the first step of reaction, the reaction temperature at this time is controlled at 140°C-150°C, and the stirring speed should be adjusted according to the viscosity of the material during the stirring reaction. After the reaction is completed and ...

Embodiment 2

[0015] Embodiment 2: Calcium-zinc composite stabilizer applied to PVC wire and cable materials

[0016] The preparation process of the stabilizer: 30 parts of fatty acid, 10 parts of calcium hydroxide, 20 parts of zinc oxide, 3.3 parts of hydrogen peroxide and glacial acetic acid mixed solution (molar ratio 5:1~8:1) were weighed respectively by molar parts, and the fatty acid Put it into the reaction kettle and heat it to dissolve (the melting temperature at this time is controlled between 60°C-80°C), and then add zinc oxide under the conditions of stirring speed of 80-150 rpm and reaction temperature of 110°C-130°C. And control the adding speed of the mixed solution of catalyst hydrogen peroxide and glacial acetic acid, add calcium hydroxide after the first step of reaction, the reaction temperature at this time is controlled at 140°C-150°C, and the stirring speed should be adjusted according to the viscosity of the material during the stirring reaction. After the reaction is...

Embodiment 3

[0018] Embodiment 3: the calcium-zinc composite stabilizer that is applied to PVC profiled material:

[0019] The preparation process of the stabilizer: Weigh 28 parts of fatty acid, 16 parts of calcium hydroxide, 13 parts of zinc oxide, 3.0 parts of hydrogen peroxide and glacial acetic acid mixed solution (molar ratio 5:1~8:1), and weigh the fatty acid Put it into the reaction kettle and heat it to dissolve (the melting temperature at this time is controlled between 60°C-80°C), and then add zinc oxide under the conditions of stirring speed of 80-150 rpm and reaction temperature of 110°C-130°C. And control the adding speed of the mixed solution of catalyst hydrogen peroxide and glacial acetic acid, add calcium hydroxide after the first step of reaction, the reaction temperature at this time is controlled at 140°C-150°C, and the stirring speed should be adjusted according to the viscosity of the material during the stirring reaction. After the completion of the reaction, it is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com