A kind of preparation method of anti-yellowing liquid optical glue

An optical adhesive and anti-yellowing technology, which is applied in the field of preparation of anti-yellowing liquid optical adhesives, can solve the problems of large curing shrinkage, reduced adhesive strength, weak adhesive force and the like, and achieves a simple and easy preparation method, Improved uniformity and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

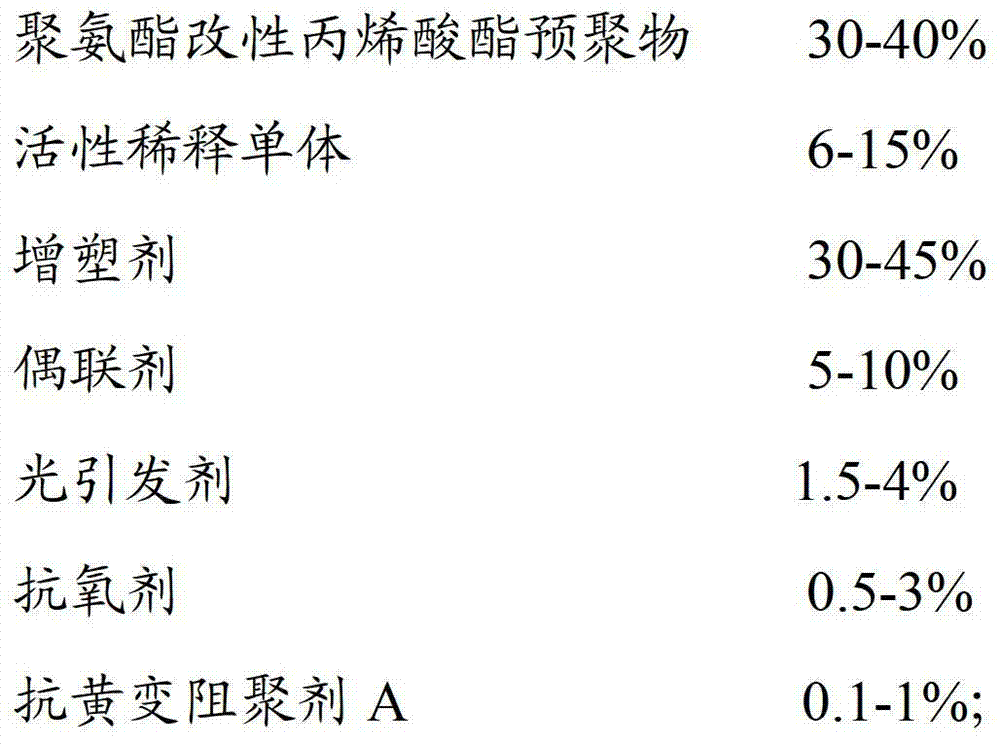

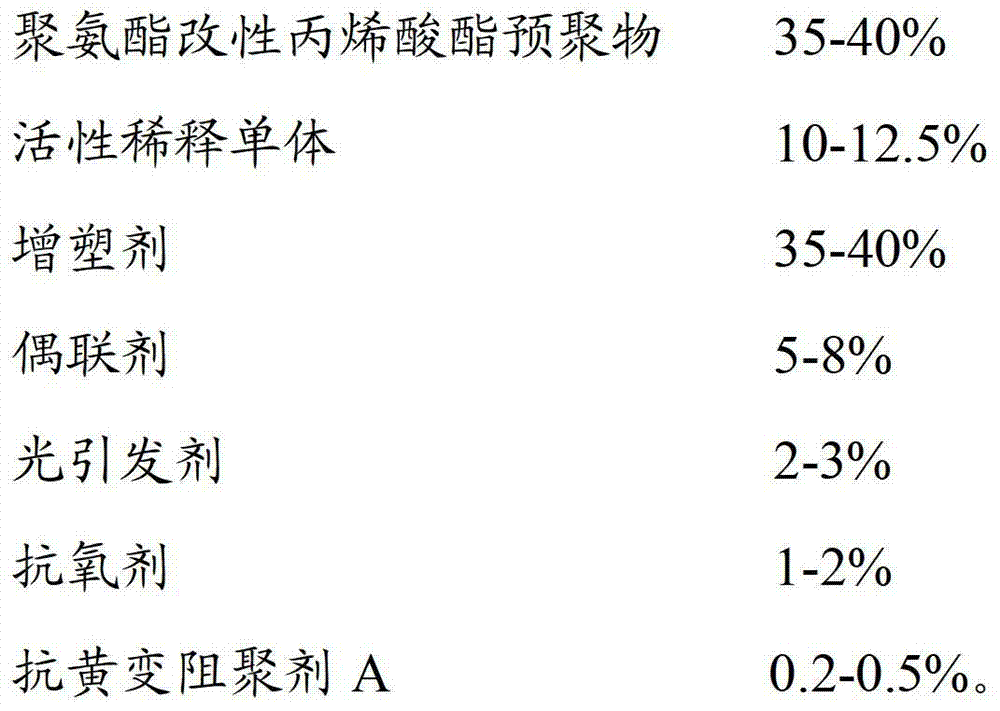

Method used

Image

Examples

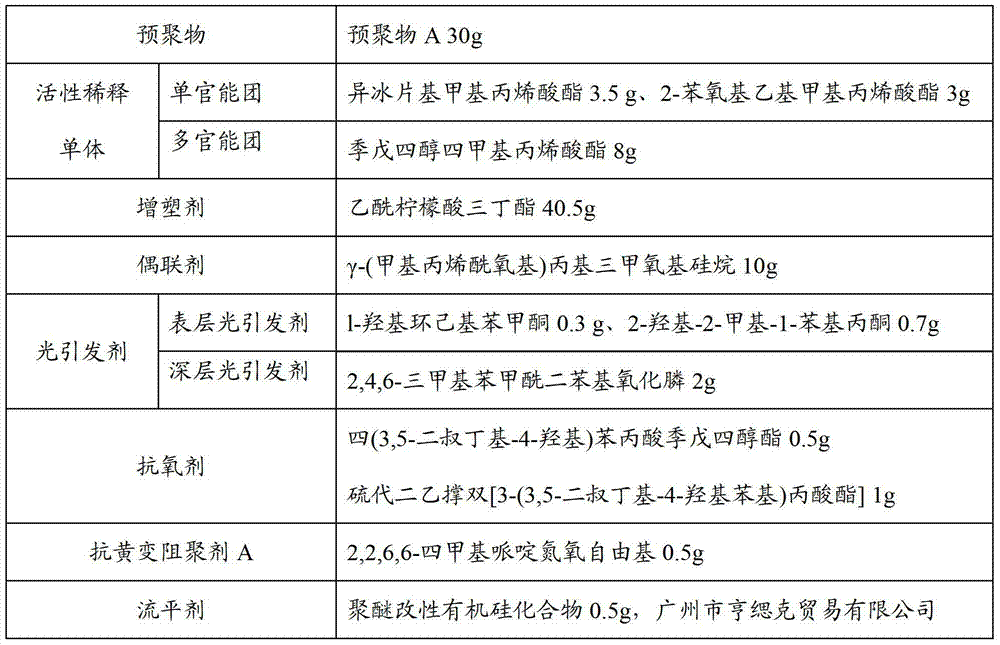

Embodiment 1

[0038] To prepare yellowing-resistant liquid optical adhesive, first prepare a polyurethane-modified acrylate prepolymer, denoted as prepolymer A, and the preparation method is as follows:

[0039] Add 113g polypropylene glycol (PPG-2000, Jiangsu Haian Petrochemical Plant) and 87g polycaprolactone diol (molecular weight 2000, Japanese Daicel) into a flask with a thermometer, suction port and stirring device, and heat to 100 ℃, vacuum dehydration for 2h, use Karl Fischer method to determine the moisture content below 0.05%, add 0.2g of catalyst dibutyltin dilaurate, heat up to 115℃, drop 23.8g isophorone diisocyanate and 16.5g diisocyanate Cyclohexylmethane diisocyanate (HMDI), stir and react for 5h, then add 18.9g hydroxypropyl acrylate and 0.1g catalyst dibutyltin dilaurate, 0.2g 2,2,6,6-tetramethylpiperidine nitroxide free After the reaction is completed, the isocyanate group is measured at 2270 cm by infrared spectroscopy. -1 The stretching vibration peak at the position drops...

Embodiment 2

[0044] To prepare the yellowing-resistant liquid optical adhesive, first prepare a polyurethane-modified acrylate prepolymer, denoted as prepolymer B. The preparation method includes the following steps:

[0045] Add 129g of polytetrahydrofuran glycol with a molecular weight of 2000 (PTMEG-2000, BASF) and 107g of polycaprolactone diol (molecular weight of 3000, Japanese Daicel) into a flask equipped with a thermometer, a suction port and a stirring device. Dehydrate under vacuum for 2.5 hours at 100°C, use Karl Fischer method to determine moisture content below 0.05%, add 0.095g of catalyst dibutyltin dilaurate, heat up to 100°C, add 27g isophorone diisocyanate and 14g dropwise Dicyclohexylmethane diisocyanate (HMDI), stir and react for 4h, then add 27.6g o-hydroxycyclohexyl methacrylate and 0.35g catalyst dibutyltin dilaurate, 0.12g 2,2,6,6-tetramethyl Piperidine nitroxide radical, continue to react at 80℃ for 6h, the reaction is complete, the isocyanate group is measured at 227...

Embodiment 3

[0050] To prepare the yellowing-resistant liquid optical adhesive, first prepare a polyurethane modified acrylate prepolymer, denoted as prepolymer C, and the preparation method includes the following steps:

[0051] Add 180g polypropylene glycol (PPG-3000, Jiangsu Haian Petrochemical Plant) and 80g polycaprolactone diol (molecular weight 2000, Japanese Daicel) into a flask with a thermometer, suction port and stirring device, and heat to 90 ℃, vacuum dehydration for 1h, use Karl Fischer method to determine the moisture content below 0.05%, add 0.39g of catalyst dibutyltin dilaurate, heat up to 90℃, drop 26g isophorone diisocyanate and 12.4g bicyclic Hexylmethane diisocyanate (HMDI), stir and react for 6h, then add 20.2g 2-hydroxyethyl methacrylate and 0.39g catalyst dibutyltin dilaurate, 0.26g 2,2,6,6-tetramethylpiperidine nitrogen Oxygen radicals, continue to react at 90°C for 7h. After the reaction is complete, the isocyanate group at 2270cm is determined by infrared spectrosc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com