A method for enriching gallium in the mother liquor of alumina production process from high-alumina fly ash

A technology of high-aluminum fly ash and process mother liquor, applied in the direction of improving process efficiency, can solve problems such as damage to equipment and operators, unfavorable industrial production, environmental pollution of hydrochloric acid, etc., and achieve significant environmental and economic effects and resource utilization. High and efficient enrichment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

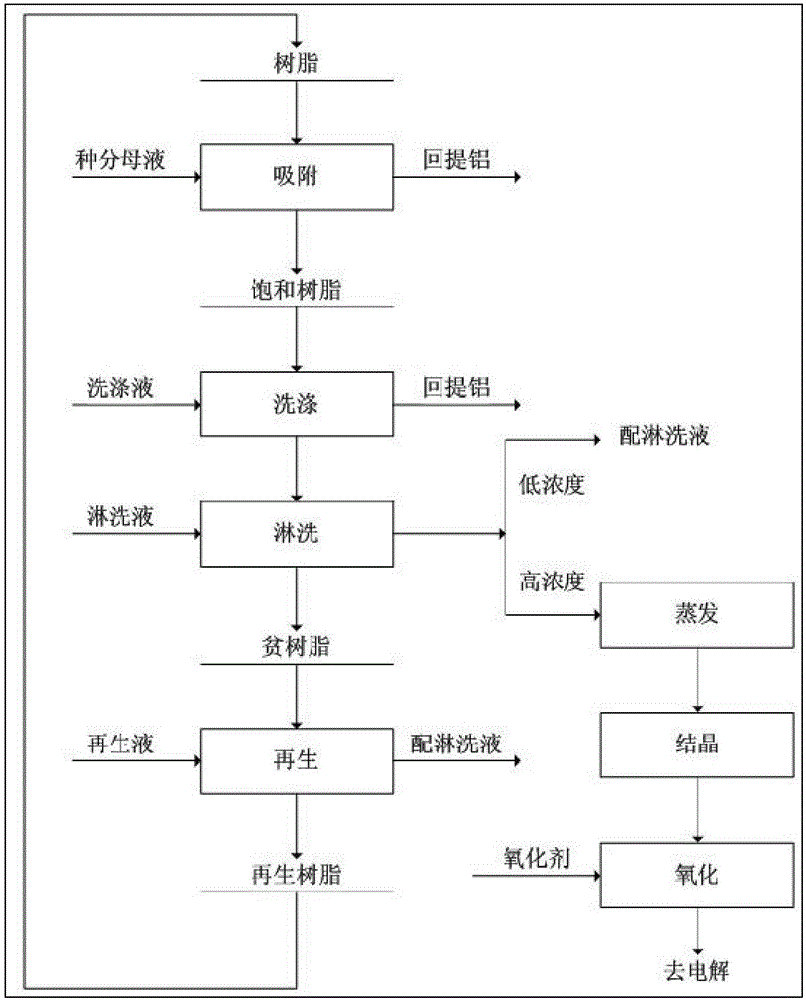

Method used

Image

Examples

Embodiment 1

[0066] Use a resin with an amidoxime structure produced by a resin factory to activate the column, and the capacity of the resin column is about 300ml. The concentration of gallium in the mother liquor used as a raw material is 80-100ppm. The mother liquor is fed into the column at a flow rate of 12.5ml / min, and it penetrates completely after about 16 hours. The concentration of gallium in the effluent liquid is more than 90% of the concentration of the original mother liquor. . Use 2mol / L potassium hydroxide solution as the washing solution, and still feed the washing solution at a flow rate of 12.5ml / min, and the washing will end after about 75 minutes. Use an aqueous solution containing 1mol / L sodium sulfide and 3mol / L sodium hydroxide as the eluent, and put the eluent on the column at a rate of 2.5ml / min for about 40 hours. Among them, the eluent in the 0-2 hours and > 6 hours is a low-concentration enrichment solution, which can be returned to reconstitute the eluent; th...

Embodiment 2

[0068] Use the resin of acrylonitrile-divinylbenzene structure with amidoxime structure produced by a resin factory, and pack it into a column after activation. The capacity of the resin column is about 600ml. The concentration of gallium in the seed liquor as raw material is 100-120ppm, and the flow rate of the seed liquor is 20ml / min. After about 20 hours, the concentration of the effluent reaches more than 90% of that of the original seed liquor. Use 4 mol / L potassium hydroxide solution as the washing liquid, and still enter the washing liquid at the same flow rate, and the washing ends after about 90 minutes. Use an aqueous solution containing 0.5mol / L sodium sulfide and 4.2mol / L sodium hydroxide as the eluent, and the eluent passes through the resin column at a rate of 5ml / min, and the complete eluting time is about 40 hours. Among them, the eluent in the 0-2 hours and > 6 hours is a low-concentration enrichment solution, which can be returned to reconstitute the eluent; ...

Embodiment 3

[0070] Use the resin of acrylonitrile-divinylbenzene structure with amidoxime structure produced by a resin factory, and pack it into a column after activation. The capacity of the resin column is about 1500ml. The concentration of gallium in the mother liquor used as a raw material is 60-80ppm, and the mother liquor is passed into the column at a flow rate of 50ml / min. After about 20 hours, the concentration of the effluent is about 90% of the concentration of the original mother liquor. . Use 1mol / L potassium hydroxide solution as the washing solution, and still feed the washing solution at a flow rate of 50ml / min, and the washing will end after about 90 minutes. Use an aqueous solution containing 0.6mol / L sodium sulfide and 1mol / L sodium hydroxide as the eluent, and the eluent passes through the column at a rate of 12.5ml / min for about 40 hours. Among them, the eluent in the 0-4 hours and > 8 hours is a low-concentration enrichment solution, which can be returned to recons...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com