Refining device and method of high purity silicon

A refining device and high-purity technology, applied in chemical instruments and methods, silicon compounds, inorganic chemistry, etc., can solve the problems of small plasma action range, large power consumption, high cost, etc., achieve considerable market prospects and improve utilization rate , low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] 1) Weigh 300kg of industrial silicon with a purity of 99%, and its boron and phosphorus contents are 1-2ppmw and 5-6ppmw respectively.

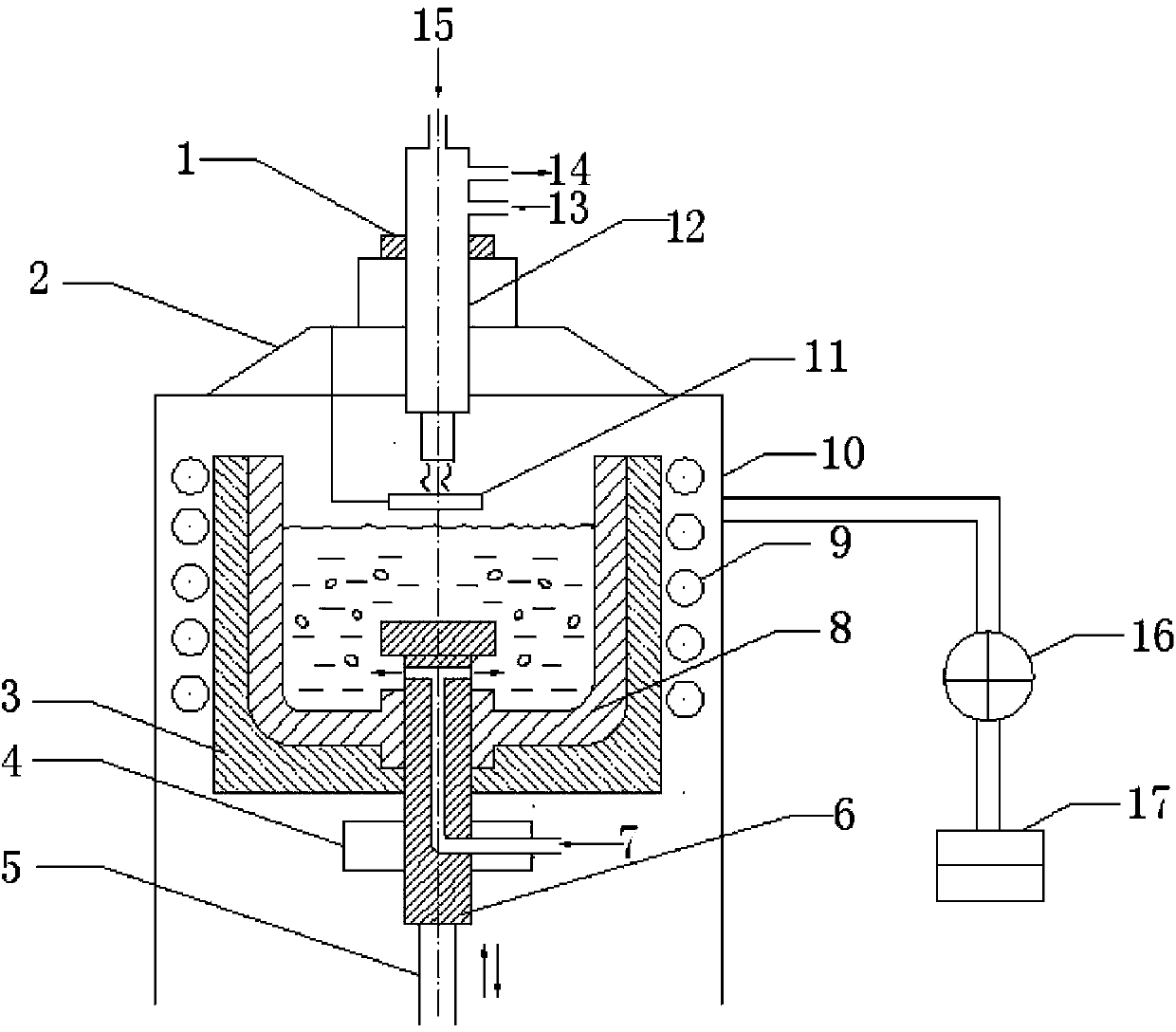

[0049] 2) Put the silicon material into the graphite crucible, start the vacuum system to evacuate, when the vacuum reaches 10Pa, turn on the power supply of the intermediate frequency induction melting furnace, adjust the power to 300kW, and heat the silicon material.

[0050] 3) Increase the power of the medium-frequency induction melting furnace to 350kW to keep the silicon liquid at 1600°C.

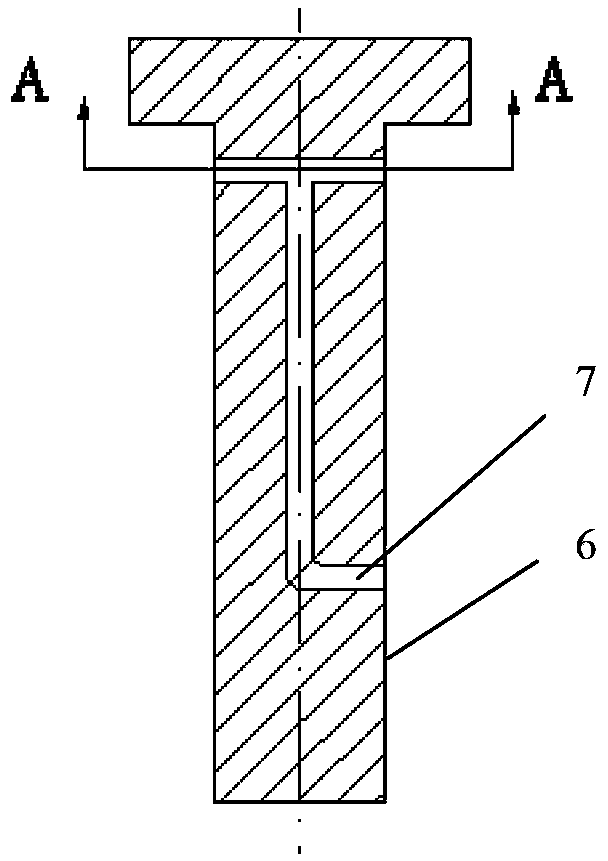

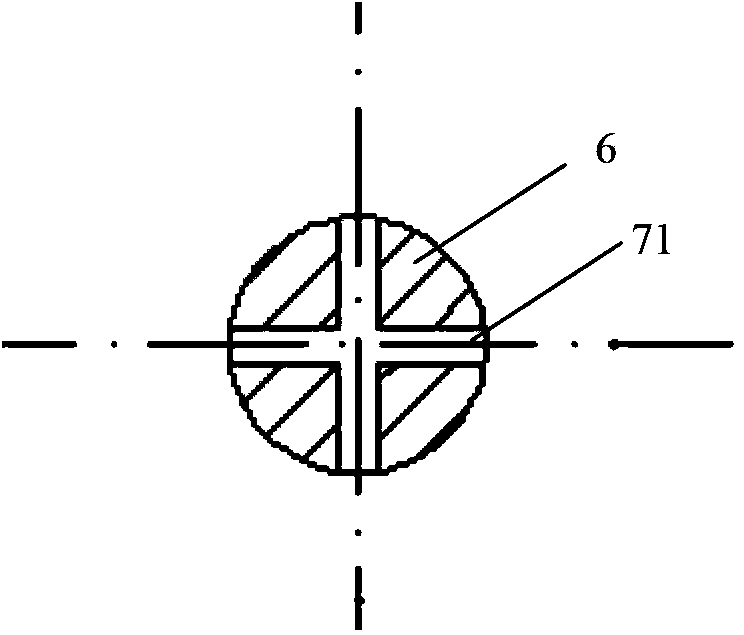

[0051] 4) Start the venting plug device and the plasma melting device, feed the mixed gas of argon and water vapor with a volume fraction of 99.5% and 0.5% respectively into the gas pipe of the venting plug, and then raise the venting plug until the gas outlet is far from the bottom of the graphite crucible 10mm. The ventilation rate is 20L / min, the melting time is 45min, and the water vapor content can be controlled by a hygrometer. The pow...

Embodiment 2

[0055] Raw material and technological process are with embodiment 1. Increase the power of the medium-frequency induction melting furnace to 400kW to keep the silicon liquid at 1700°C. A mixed gas of argon and water vapor with a volume fraction of 99% and 1% was passed into the silicon liquid, the gas flow rate was 25L / min, and the melting time was 50min. Pour the silicon liquid into the graphite mold for casting, take out the silicon ingot after standing for cooling, remove 1 / 10 of the head and the tail, and measure the B content in the polysilicon ingot by plasma inductively coupled mass spectrometer (ICP-MS) to be 0.12ppmw, P The content is 0.31ppmw.

Embodiment 3

[0057] Raw material and technological process are with embodiment 1. Increase the power of the medium-frequency induction melting furnace to 450kW to keep the silicon liquid at 1750°C. A mixture of argon and water vapor with a volume fraction of 98.5% and 1.5% was passed into the silicon liquid, the gas flow rate was 30L / min, and the melting time was 60min. Pour the silicon liquid into the graphite mold for casting, take out the silicon ingot after standing for cooling, remove 1 / 10 of the head and tail, and measure the B content in the polysilicon ingot by plasma inductively coupled mass spectrometer (ICP-MS) to be 0.10ppmw, P The content is 0.33ppmw.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com