High-yield co-production method of D-gluconic acid-delta-lactone, mannose and mannitol

A technology of gluconic acid and mannose, applied in chemical instruments and methods, monosaccharides, sugar derivatives, etc., can solve problems such as increasing production process costs, and achieve the effects of improving yield and improving economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

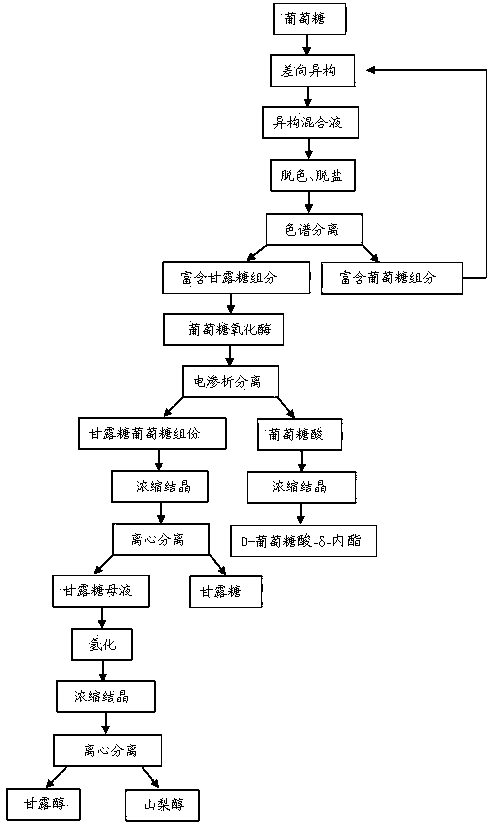

[0026] The method for high yield co-production of D-glucono-δ-lactone, mannose and mannitol described in this embodiment comprises the following steps, such as figure 1 Shown:

[0027] 1. Dissolve 5.5 kg of crystalline glucose monohydrate (contains one crystal water molecule, 5 kg of dry matter) in 4.5 kg of deionized water to obtain a solution with a concentration of 50%, add hydrochloric acid to adjust the pH to 3.0, and add catalyst ammonium molybdate 5 g, carried out epimerization reaction at 110 ° C for 1 hour, and then desalted and refined by ion exchange resin to obtain a mannose content of 30.5% in the heterogeneous mixture.

[0028] 2. Send the above-mentioned heterogeneous mixed solution into a chromatographic separation device to obtain a mannose-rich component and a glucose-rich component; the mass percentage concentration of mannose and glucose in the mannose-rich component is 17% , wherein the content of mannose in the total sugar is 72%, the concentration in th...

Embodiment 2

[0035] The method for high yield co-production of D-glucono-δ-lactone, mannose and mannitol described in this example comprises the following steps:

[0036] 1. Dissolve 5.5 kg of crystalline glucose monohydrate (containing one crystalline water molecule, 5 kg of dry matter) in 5 kg of deionized water to obtain a solution with a concentration of 47.6%, add hydrochloric acid to adjust the pH to 3.5, and add catalyst ammonium molybdate 5 g was subjected to epimerization at 115°C for 1 hour, and then desalted and refined by ion exchange resin to obtain a mannose content of 30.2% in the heterogeneous mixture.

[0037]2. Desalting and refining the above-mentioned heterogeneous mixed solution through ion exchange resin into a chromatographic separation device to obtain a mannose-rich component and a glucose-rich component; the mannose-rich glucose content in the mannose-rich component The mass percentage concentration is 17%, the content of mannose in the total sugar is 73%, the mas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com