Method of preparing lithium battery vanadate positive materials by utilizing hydrothermal method

A cathode material, lithium battery technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of electrochemical performance limitation, serious particle agglomeration, long reaction time, etc., to achieve short preparation cycle, high purity, low production cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

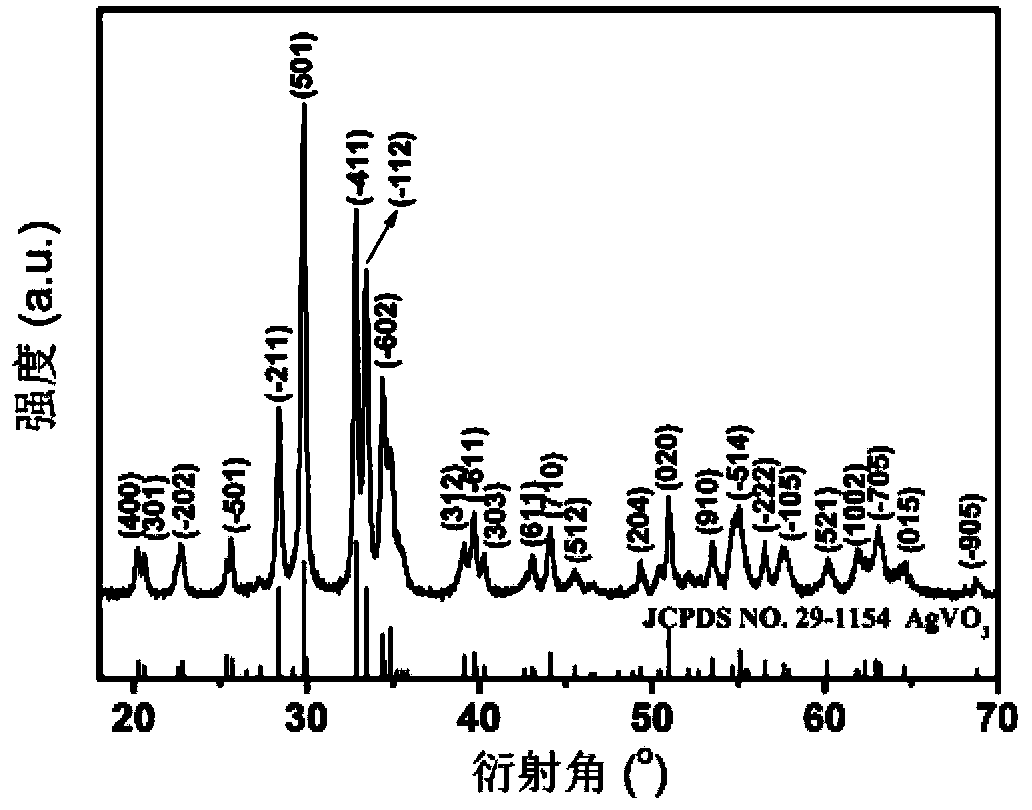

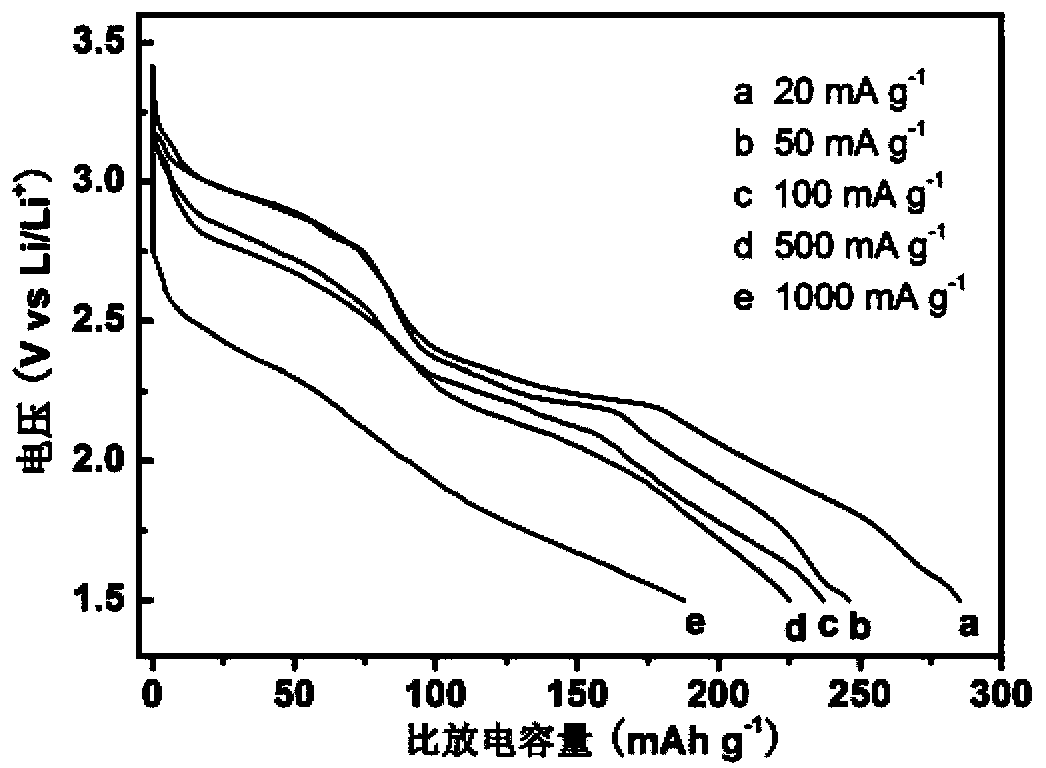

[0023] Weigh 0.3g NH 4 VO 3 Add 35ml of deionized water into a beaker, then add 2ml of hydrogen peroxide with a volume fraction of 30%, and stir on a magnetic stirrer until the solution turns yellow; weigh another 0.4356g of AgNO 3 Slowly add to the above solution, continue to stir for 20 minutes to mix evenly to obtain a clear solution; then transfer the obtained solution to a 50mL autoclave, conduct a hydrothermal reaction at 190°C for 24 hours, and cool to room temperature with the furnace; after centrifugation, Then dry it in a blast oven at 60°C to get AgVO 3 Cathode material. figure 1 It is the XRD spectrum of Example 1 of the present invention. As can be seen from the figure, the synthesized material has good crystallinity and high purity. figure 2 Shown is the AgVO prepared by embodiment 1 3 Scanning electron microscope image of the cathode material. The AgVO that embodiment 1 obtains 3 The positive electrode material is in the form of a nanoribbon structure wi...

Embodiment 2

[0027] Weigh 0.8g NH 4 VO 3 Add 35ml of deionized water into a beaker, then add 2ml of hydrogen peroxide with a volume fraction of 30%, and stir on a magnetic stirrer until the solution turns yellow; add 0.0439g of NaF to the above solution slowly, and continue stirring for 20 minutes to make Mix them evenly to obtain a clear yellow solution; then transfer the obtained solution to a 50mL autoclave for hydrothermal reaction at 205°C for 48 hours, then cool to room temperature with the furnace; Drying; the resulting material is raised to 300-500°C for 4 hours at a heating rate of 5°C / min in a muffle furnace to obtain sodium vanadate Na 0.33 V 2 o 5 Cathode material. Figure 4 It is the XRD spectrum of Example 2 of the present invention. As can be seen from the figure, the synthesized material has good crystallinity and high purity.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com