Composite fine barium sulfate and manufacturing method thereof

A barium sulfate, fine technology, applied in dyeing organosilicon compound treatment, dyeing low-molecular-weight organic compound treatment, dyeing physical treatment, etc. Good durability, corrosion resistance and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

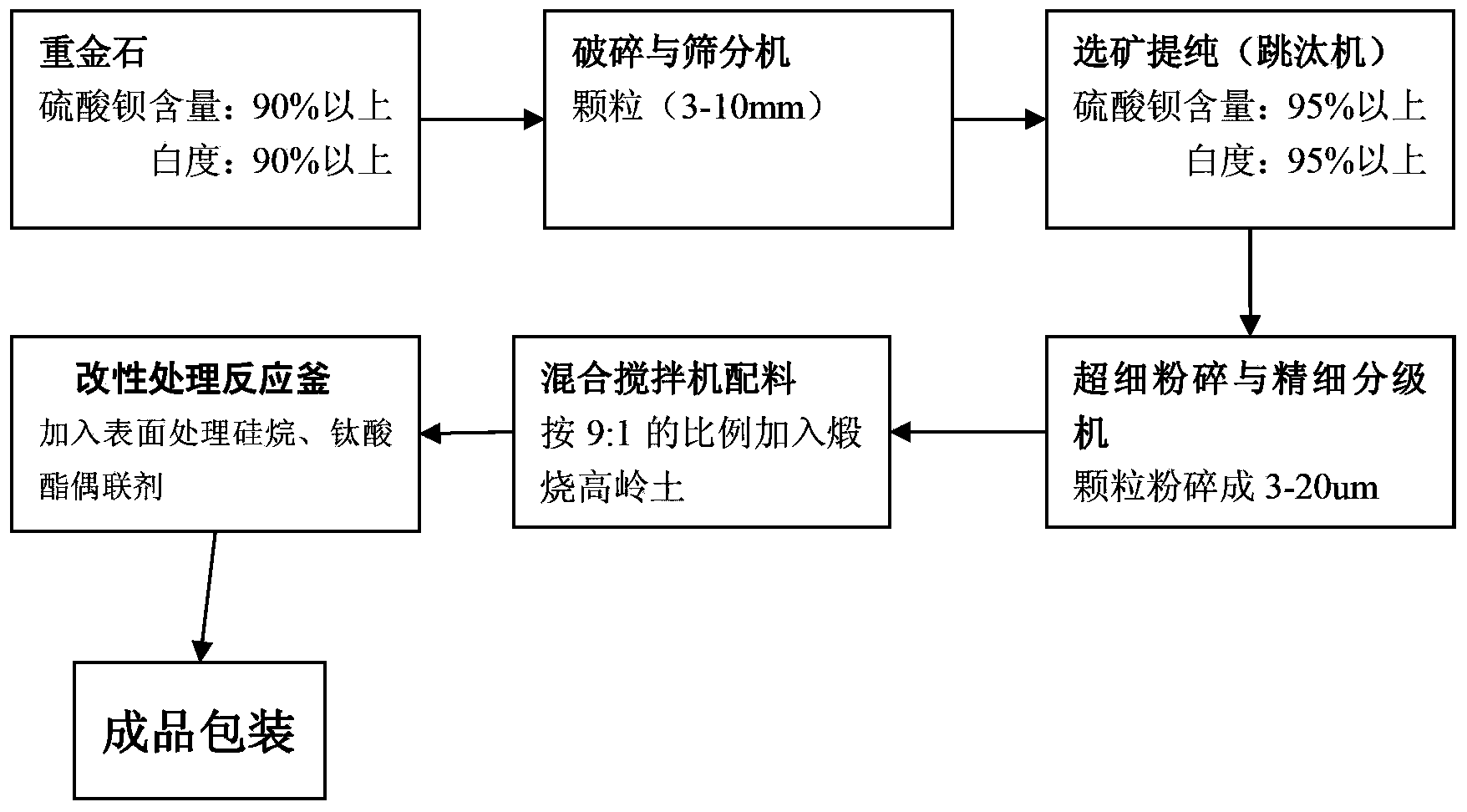

[0022] Composite fine barium sulfate, including barium sulfate and kaolin, the barium sulfate is crushed and sieved from heavy gold stone, after mineral processing and purification, the content and whiteness are both above 90%, and then through ultrafine grinding and fine classification. - Barium sulfate particles of 20 microns, then fully mixed with kaolin at a weight ratio of 6:1-12:1, and finally added a small amount of surface modifier and coupling agent to mix.

[0023] In this embodiment, the content and whiteness of the barium sulfate obtained through ore dressing and purification are between 93%-98%, preferably about 95%; the surface modifier is silane, and the coupling agent is titanate; The weight ratio of the barium sulfate to kaolin is preferably 9:1.

[0024] like figure 1 Shown, the manufacture method of composite fine barium sulfate may further comprise the steps:

[0025] 1. Heavy metal crushing and screening

[0026] Choose barite raw ore size 150*250mm, ba...

PUM

| Property | Measurement | Unit |

|---|---|---|

| whiteness | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com