Production method of glucose oxidase

The technology of a glucose oxidase and production method, which is applied in the field of glucose oxidase production, can solve the problems of low fermentation activity, high production cost, and low yield, and achieve the effects of simple process, high production efficiency, and easy storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

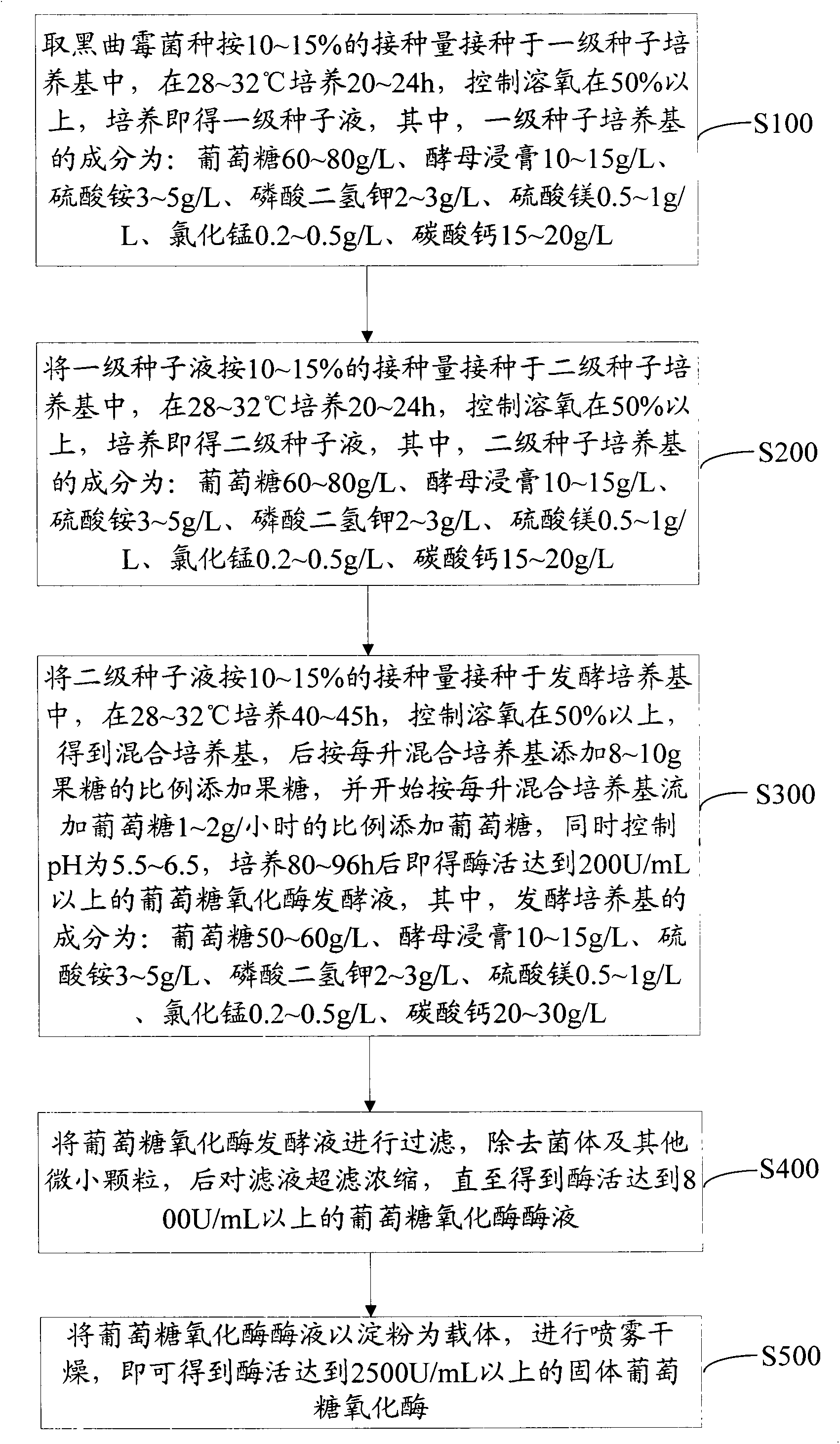

Image

Examples

Embodiment 1

[0039] A production method of glucose oxidase, comprising the following steps:

[0040] (1) Get the Aspergillus niger strain and inoculate it in the first-grade seed culture medium with an inoculum amount of 10%, cultivate it at 32° C. for 24 hours, feed sterile air to control the dissolved oxygen above 50%, and cultivate to obtain the first-grade seed liquid.

[0041]Among them, the ingredients of the primary seed medium are: glucose 60g / L, yeast extract 15g / L, ammonium sulfate 3g / L, potassium dihydrogen phosphate 3g / L, magnesium sulfate 1g / L, manganese chloride 0.2g / L , Calcium carbonate 20g / L.

[0042] (2) Inoculate the primary seed liquid in the secondary seed medium with an inoculum amount of 15%, cultivate at 28° C. for 24 hours, pass through sterile air to control dissolved oxygen above 50%, and cultivate to obtain the secondary seed liquid.

[0043] Among them, the composition of the secondary seed medium is: glucose 60g / L, yeast extract 15g / L, ammonium sulfate 3g / L, ...

Embodiment 2

[0048] A production method of glucose oxidase, comprising the following steps:

[0049] (1) Get the Aspergillus niger strain and inoculate it in the first-class seed culture medium with an inoculum amount of 15%, cultivate it at 30° C. for 20 hours, feed sterile air to control the dissolved oxygen above 50%, and cultivate to obtain the first-class seed liquid.

[0050] Among them, the ingredients of the primary seed medium are: glucose 80g / L, yeast extract 10g / L, ammonium sulfate 5g / L, potassium dihydrogen phosphate 3g / L, magnesium sulfate 0.5g / L, manganese chloride 0.2g / L L, calcium carbonate 15g / L.

[0051] (2) Inoculate the primary seed liquid into the secondary seed medium with an inoculation amount of 12%, cultivate at 32° C. for 24 hours, pass through sterile air to control dissolved oxygen above 50%, and cultivate to obtain the secondary seed liquid.

[0052] Among them, the composition of the secondary seed medium is: glucose 80g / L, yeast extract 10g / L, ammonium sulfa...

Embodiment 3

[0057] A production method of glucose oxidase, comprising the following steps:

[0058] (1) Get the Aspergillus niger strain and inoculate it in the first-grade seed culture medium according to the inoculum amount of 12%, cultivate it at 28° C. for 22 hours, adjust the stirring speed to control the dissolved oxygen above 50%, and cultivate to obtain the first-grade seed liquid.

[0059] Among them, the ingredients of the primary seed medium are: glucose 60g / L, yeast extract 15g / L, ammonium sulfate 4g / L, potassium dihydrogen phosphate 2g / L, magnesium sulfate 1g / L, manganese chloride 0.5g / L , Calcium carbonate 20g / L.

[0060] (2) Inoculate the primary seed liquid into the secondary seed medium with an inoculum amount of 10%, cultivate at 32° C. for 20 h, adjust the stirring speed to control dissolved oxygen above 50%, and cultivate to obtain the secondary seed liquid.

[0061] Among them, the composition of the secondary seed medium is: glucose 60g / L, yeast extract 15g / L, ammon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com