Preparation method of carbon-based magnetic temperature-sensitive surface imprinted adsorbent

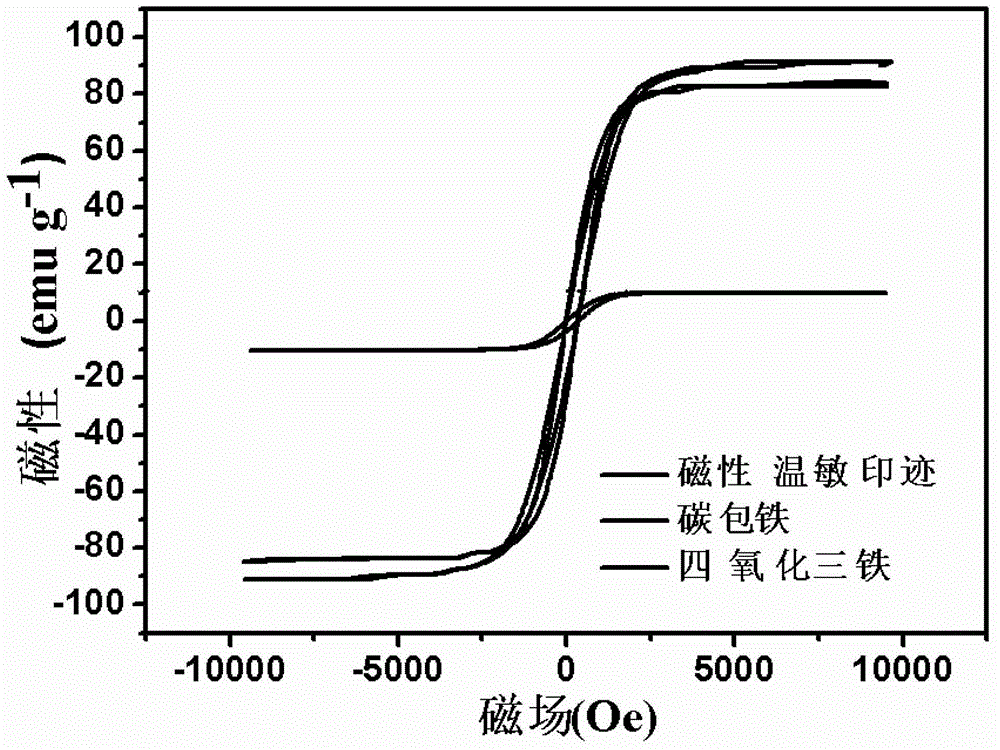

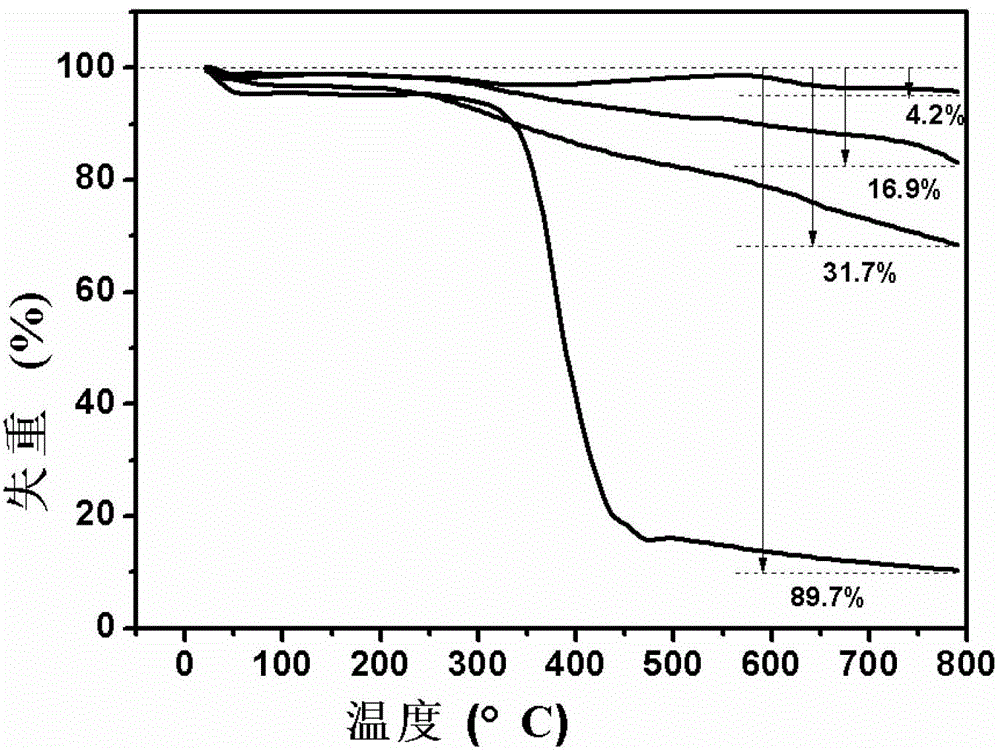

A surface imprinted, temperature-sensitive technology, applied in chemical instruments and methods, other chemical processes, etc., can solve problems such as complex components, and achieve high adsorption capacity, non-destructive, good magnetic and thermal response properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

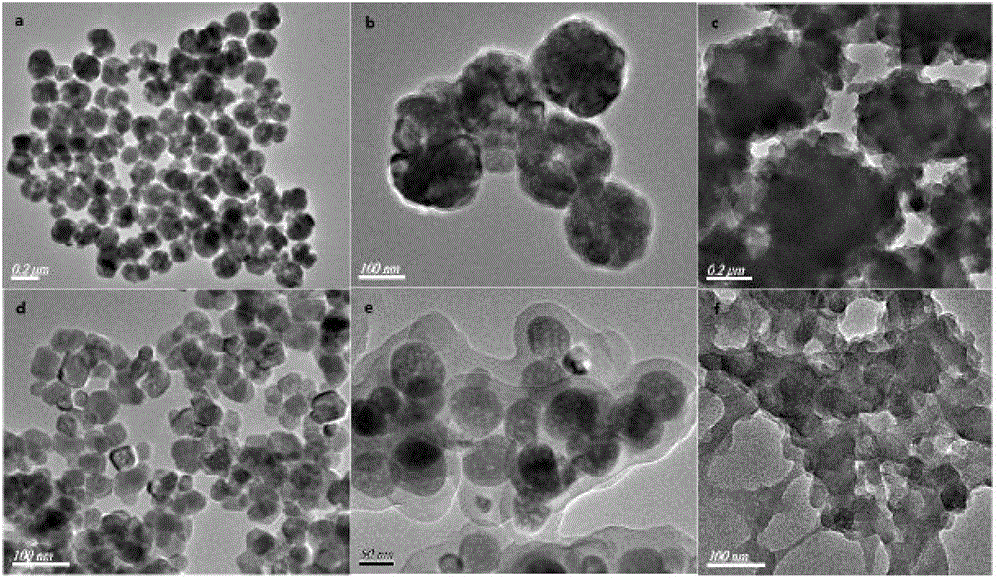

[0024] 1. A method for preparing a carbon-based magnetic temperature-sensitive surface imprinted adsorbent, characterized in that it is carried out according to the following steps:

[0025] (1) Ferric oxide (Fe 3 o 4 ) synthesis method

[0026] 4g hexahydrate and ferric chloride (FeCl 3 ·6H 2 O) and 5g of sodium acetate (NaAc) were dissolved in 40ml of ethylene glycol, and the mixture was stirred at 130°C for 1h under nitrogen protection, then transferred to a 100ml reactor, reacted at 150°C for 8h, cooled to room temperature, black The magnetic Fe3O4 was washed several times with absolute ethanol and dried at 50°C for 4h.

[0027] (2) Magnetic carbon sphere composites (Fe 3 o 4 C) Preparation

[0028] Fe 3 o 4 Microspheres 0.1g, glucose 4g, PEG ( M W =1500) 0.3g, dissolved in 10ml of distilled water, ultrasonic 10min, the mixture was stirred for 30 minutes, then put into the reaction kettle, heated to 150°C, the temperature was raised for 3h, kept for 6h, coo...

Embodiment 2

[0042] 1. A method for preparing a carbon-based magnetic temperature-sensitive surface imprinted adsorbent, characterized in that it is carried out according to the following steps:

[0043] (1) Synthesis method of ferric oxide (Fe3O4)

[0044] 9g of hexahydrate and ferric chloride (FeCl3 6H2O) and 10g of sodium acetate (NaAc) were dissolved in 70ml of ethylene glycol, and the mixture was stirred at 180°C for 3h under the protection of nitrogen, then transferred to a 100ml reaction kettle, and heated at 200°C The reaction was carried out for 12 hours, cooled to room temperature, the black magnetic ferric iron tetroxide was washed several times with absolute ethanol, and dried at 60°C for 8 hours.

[0045] (2) Preparation of magnetic carbon sphere composite (Fe3O4C)

[0046] Fe3O4 microspheres 0.3g, glucose 7g, PEG (MW=1500) 0.6g, dissolved in 25ml distilled water, ultrasonicated for 20min, the mixture was stirred for 30min, then put into the reaction kettle, heated to 200°C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com