Lithium ion battery cathode material and preparation method thereof

A technology for lithium ion batteries and negative electrode materials, applied in the field of electrochemical materials, can solve problems such as insufficient performance of negative electrode materials, achieve good application development prospects, improve electronic conductivity, and have the effects of strong operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] The preparation of ferrous carbonate: comprise the following steps:

[0039] S1. Add 0.200 g of sodium lauryl sulfate into 40 mL of deionized water, stir it mechanically to completely dissolve it, and obtain solution A.

[0040] S2. Ferrous sulfate is added in solution A, the molar concentration of ferrous sulfate is 0.02mol / L, mechanically stirred until completely dissolved, obtains solution B.

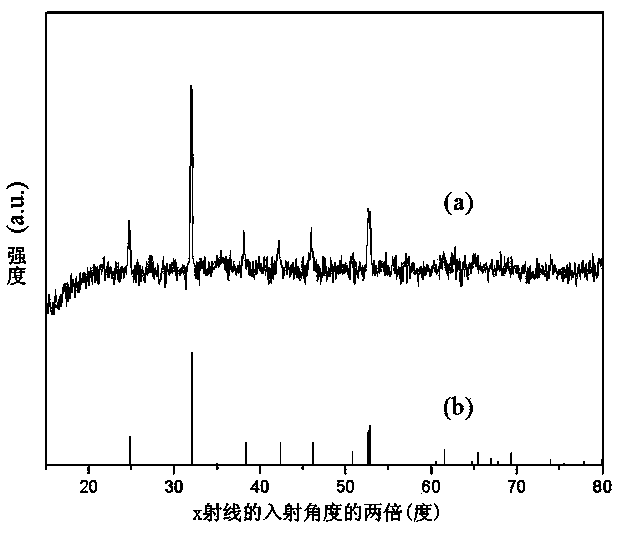

[0041] S3. Add urea to solution B according to the molar concentration ratio of urea and ferrous sulfate is 50:1, after mechanical stirring makes it completely dissolved, adjust solution pH=4 with hydrochloric acid to obtain solution C, and then transfer solution C to poly In a tetrafluoroethylene-lined stainless steel reactor, the reactor was then placed in a blast oven at 100°C for 8 hours of reaction, and the reaction product was repeatedly washed with deionized water and ethanol to obtain a siderite-type ferrous carbonate negative electrode material. Such as figure 1 As ...

Embodiment 2

[0046] The preparation method of ferrous carbonate comprises the following steps:

[0047] S1. Add 0.200g of sodium lauryl sulfate into 40mL of deionized water, stir it with magnetic force to completely dissolve it, and obtain solution A.

[0048] S2. Ferrous sulfate is added in solution A, the molar concentration of ferrous sulfate is 0.05mol / L, magnetic stirring makes it dissolve completely, obtains solution B.

[0049] S3. Then add urea to solution B according to the molar concentration ratio of urea and ferrous sulfate is 30:1, after magnetic stirring to make it completely dissolved, adjust the pH of the solution to 2 with hydrochloric acid to obtain solution C, and then transfer solution C to Put the polytetrafluoroethylene-lined stainless steel reaction kettle, and then place the reaction kettle in a blast oven at 120°C for 8 hours of reaction, and wash the reaction product repeatedly with deionized water and ethanol to obtain ferrous carbonate.

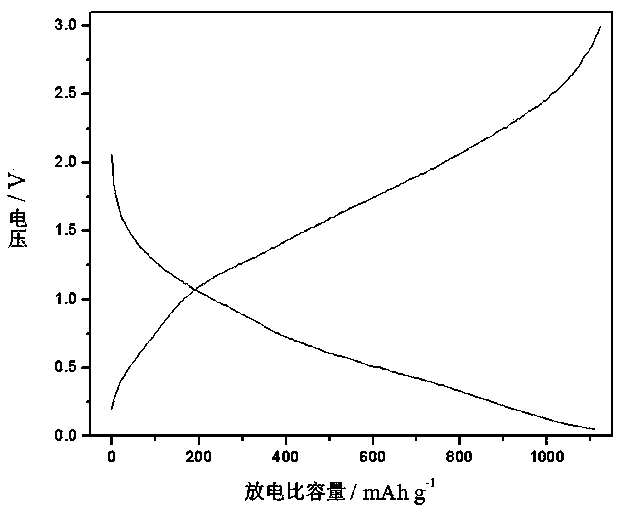

[0050] The electrochem...

Embodiment 3

[0054] The preparation method of ferrous carbonate comprises the following steps:

[0055] S1. Add 0.200 g of sodium lauryl sulfate into 40 mL of deionized water, stir it mechanically to completely dissolve it, and obtain solution A.

[0056] S2. Ferrous sulfate is added in solution A, the molar concentration of ferrous sulfate is 0.10mol / L, mechanically stirred until completely dissolved, obtains solution B.

[0057] S3. Add urea into solution B according to the molar concentration ratio of urea and ferrous sulfate as 20:1, after mechanical stirring makes it dissolve completely, adjust the pH of the solution to 6 with hydrochloric acid to obtain solution C, then transfer solution C to Put the polytetrafluoroethylene-lined stainless steel reaction kettle, then place the reaction kettle in a blast oven at 160°C for 8 hours, and wash the reaction product repeatedly with deionized water and ethanol to obtain ferrous carbonate.

[0058] The electrochemical performance test of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| First discharge specific capacity | aaaaa | aaaaa |

| First discharge specific capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com