Method for controlling N-type 4H-SiC homogenous epitaxial doping

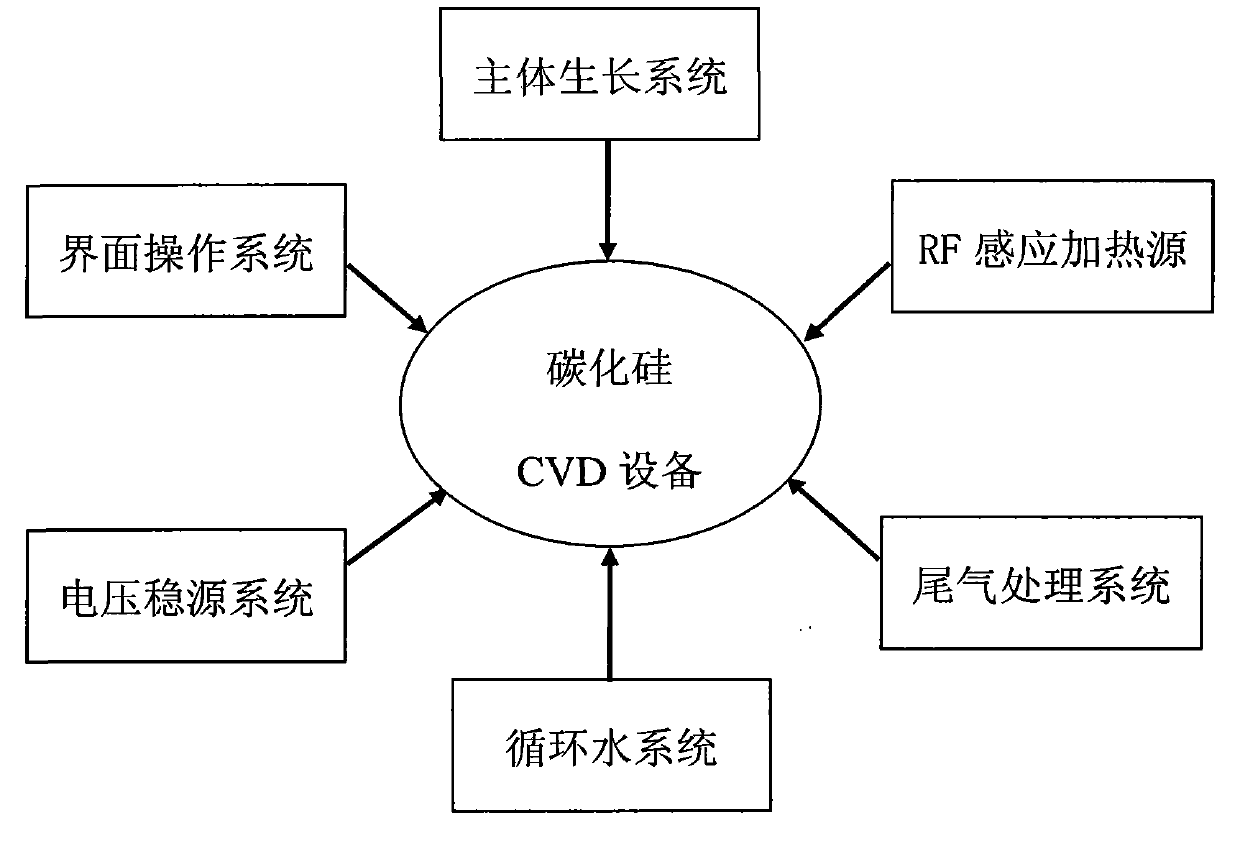

A technology of homoepitaxy and control methods, applied in the directions of diffusion/doping, chemical instruments and methods, from chemically reactive gases, etc., to achieve the effect of simplifying the preparation process, reducing defects, and improving device performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

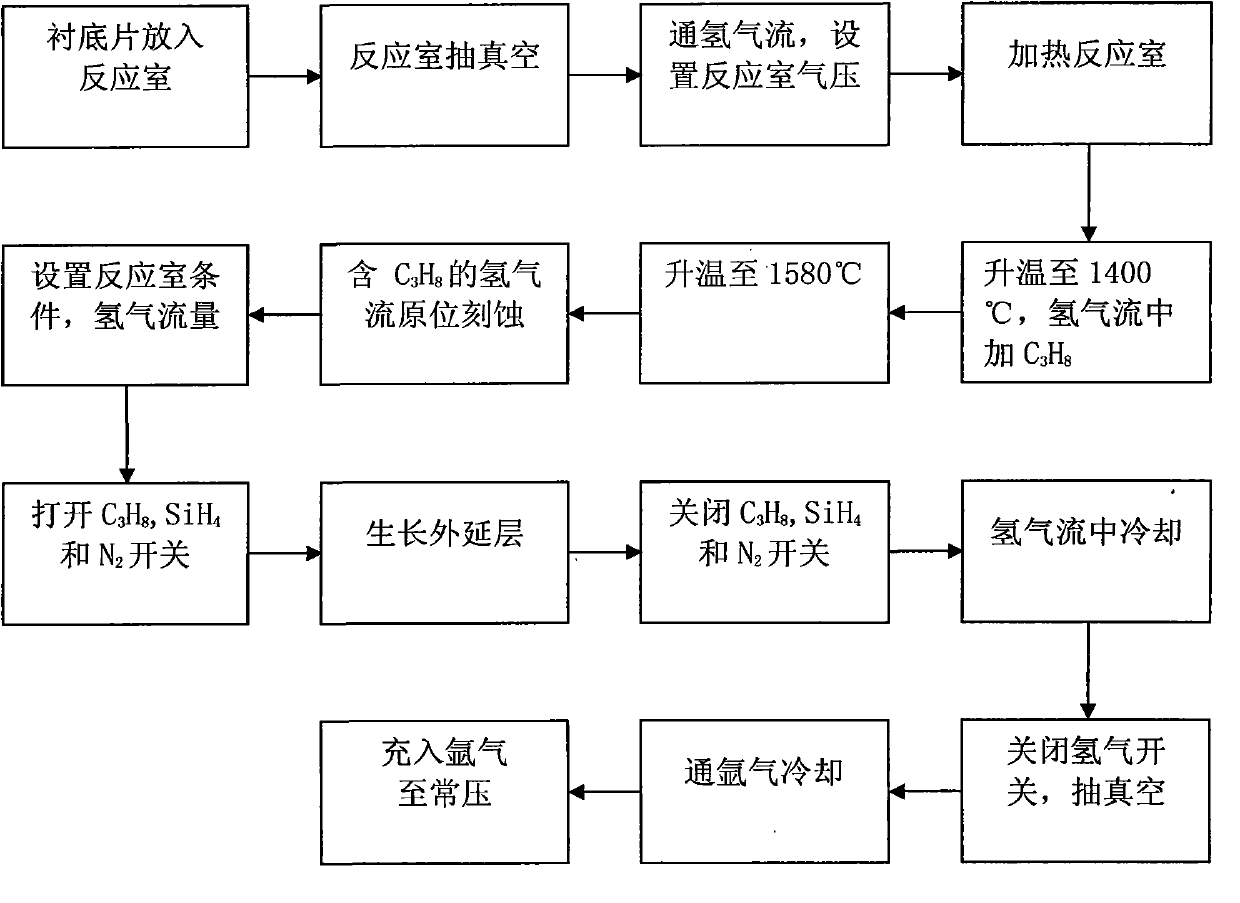

[0026] Step 1, placing the silicon carbide substrate into the reaction chamber of the silicon carbide CVD equipment.

[0027] (1.1) Selection bias A 4H silicon carbide substrate with a crystal orientation of 8° is placed in the reaction chamber of the silicon carbide CVD equipment;

[0028] (1.2) Vacuumize the reaction chamber until the pressure in the reaction chamber is lower than 1×10 -7 mbar.

[0029] Step 2, heating the reaction chamber in the hydrogen flow.

[0030] (2.1) Open the hydrogen switch leading to the reaction chamber, and control the hydrogen flow to gradually increase to 80L / min;

[0031] (2.2) Turn on the vacuum pump to extract the gas in the reaction chamber, and keep the reaction chamber pressure at 300mbar;

[0032] (2.3) Gradually increase the power of the heating source to slowly increase the temperature of the reaction chamber. When the temperature exceeds 1400°C, add C with a flow rate of 5mL / min into the hydrogen flow. 3 h 8 .

[0033] Step 3...

Embodiment 2

[0049] Step 1, choose the direction The 4H silicon carbide substrate with a crystal orientation of 8° is placed in the reaction chamber of the silicon carbide CVD equipment; the reaction chamber is evacuated until the pressure of the reaction chamber is lower than 1×10 -7 mbar.

[0050] Step 2, open the H to the reaction chamber 2 Switch, control the hydrogen flow to gradually increase to 80L / min, and at the same time turn on the vacuum pump to extract the gas in the reaction chamber, keeping the pressure of the reaction chamber at 500mbar; gradually increase the power of the RF heating source to slowly increase the temperature of the reaction chamber, when the temperature of the reaction chamber After reaching 1400°C, add C with a flow rate of 7mL / min into the hydrogen flow 3 h 8 .

[0051] Step 3, when the temperature of the reaction chamber reaches 1580°C, keep the temperature of the reaction chamber constant, and keep the flow rate of 80L / min H 2 and C at a flow rate o...

Embodiment 3

[0056] The first step is to choose a bias The 4H silicon carbide substrate with a crystal orientation of 8° is placed in the reaction chamber of the silicon carbide CVD equipment; the reaction chamber is evacuated until the pressure of the reaction chamber is lower than 1×10 -7 mbar.

[0057] In the second step, open the H to the reaction chamber 2 Switch, control the hydrogen flow to gradually increase to 80L / min, and at the same time turn on the vacuum pump to extract the gas in the reaction chamber, keeping the pressure of the reaction chamber at 700mbar; gradually increase the power of the RF heating source to slowly increase the temperature of the reaction chamber, when the temperature of the reaction chamber After reaching 1400°C, add C with a flow rate of 10mL / min into the hydrogen flow 3 h 8

[0058] In the third step, the substrate is etched in situ.

[0059] (3.1) When the reaction chamber temperature reaches 1600°C, keep the reaction chamber temperature consta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com