Fire-proof thermal-insulation photovoltaic decoration composite board and preparation method thereof

A technology of fire prevention and heat preservation, composite board, applied in the direction of photovoltaic power generation, renewable energy integration, roofing with tile/slate tile, etc. high intensity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

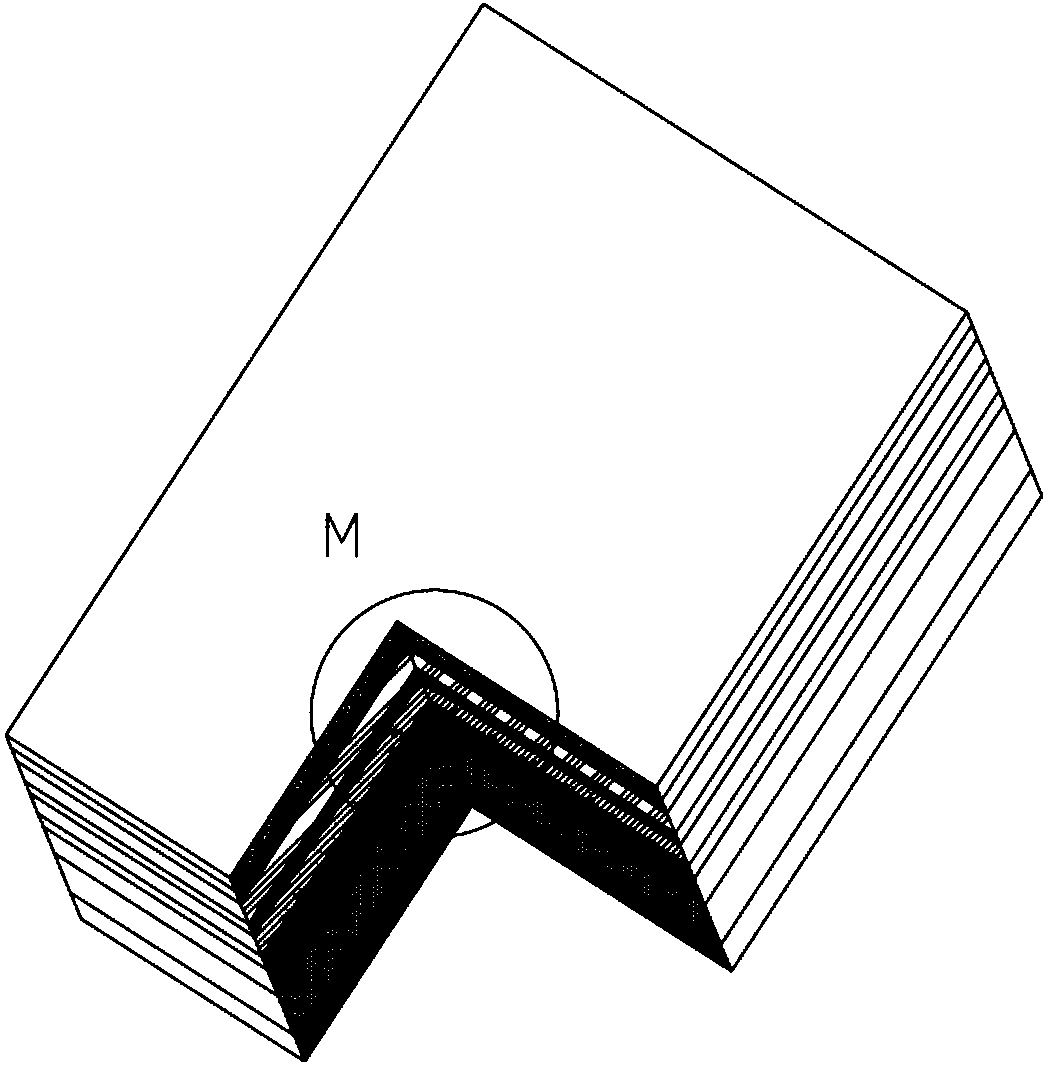

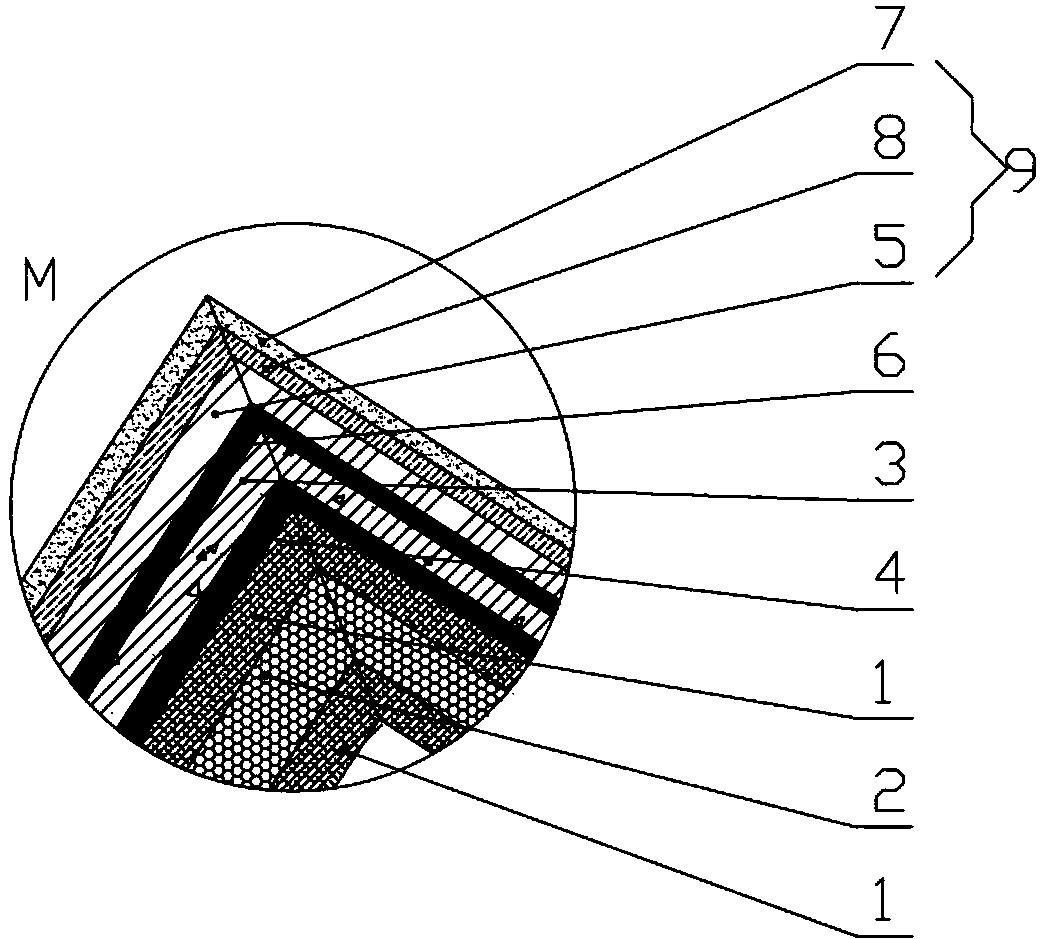

[0038] A kind of fireproof thermal insulation photovoltaic decorative composite board, such as figure 1 and figure 2 Shown is a layered structure, which includes an insulation layer 2, a reinforcement layer 3, and a photovoltaic decoration layer 9 from the inside to the outside. The insulation layer 2 is a rock wool board with a thickness of 30mm and is sealed and wrapped by a waterproof membrane 1; The rock wool fiber arrangement direction of the rock wool board is perpendicular to the horizontal plane of the rock wool board, so that the drawing strength between layers is ≥0.2MPa, and the rock wool fiber density is ≥250 g / m 3 , density ≥ 200kg / m 3 , compressive strength ≥ 0.1MPa, water repellency ≥ 98%; the waterproof membrane 1 is a polymer cement mortar polymer composite waterproof membrane, which is composed of tire base and polymer cement mortar, with a thickness of 1.5mm. The tire base is a composite felt of polyester-cotton non-woven fabric and glass fiber grid cloth...

Embodiment 2

[0041] A fireproof and thermal insulation photovoltaic decorative composite board, wherein the thickness of the thermal insulation layer 2 is 100 mm, the thickness of the waterproof coiled material 1 is 2.5 mm, and the flexible thin film battery assembly 5 is a copper indium potassium selenium thin film solar cell; the film layer 8 has a thickness of 250 um; the coating layer 7 has a thickness of 70 um, the reinforcing layer 3 is a calcium silicate board with a thickness of 5 mm, and the others are the same as in Example 1.

Embodiment 3

[0043] A fireproof and thermal insulation photovoltaic decorative composite board, wherein the thickness of the thermal insulation layer 2 is 60 mm, the thickness of the waterproof coiled material 1 is 2 mm, the flexible thin film battery assembly 5 is a cadmium telluride thin film solar cell; the thickness of the film layer 8 is The coating layer 7 has a thickness of 50 um, the reinforcing layer 3 is a cement pressure plate with a thickness of 3 mm, and the others are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com