Construction and application of SPR sensor based on amplification effect of magnetic molecularly imprinted polymer

A magnetic molecular imprinting and polymer technology, applied in the measurement of scattering characteristics, etc., can solve the problems of reducing the utilization rate of imprinting sites, large particle diffusion resistance, difficult elution of template imprinted molecules, etc., and achieve fast binding/dissociation rate, The effect of improving binding ability and good application prospect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

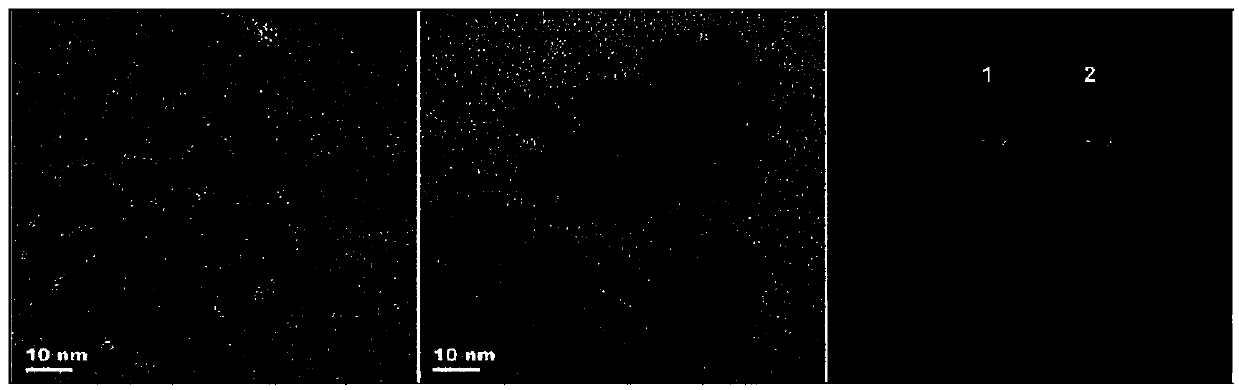

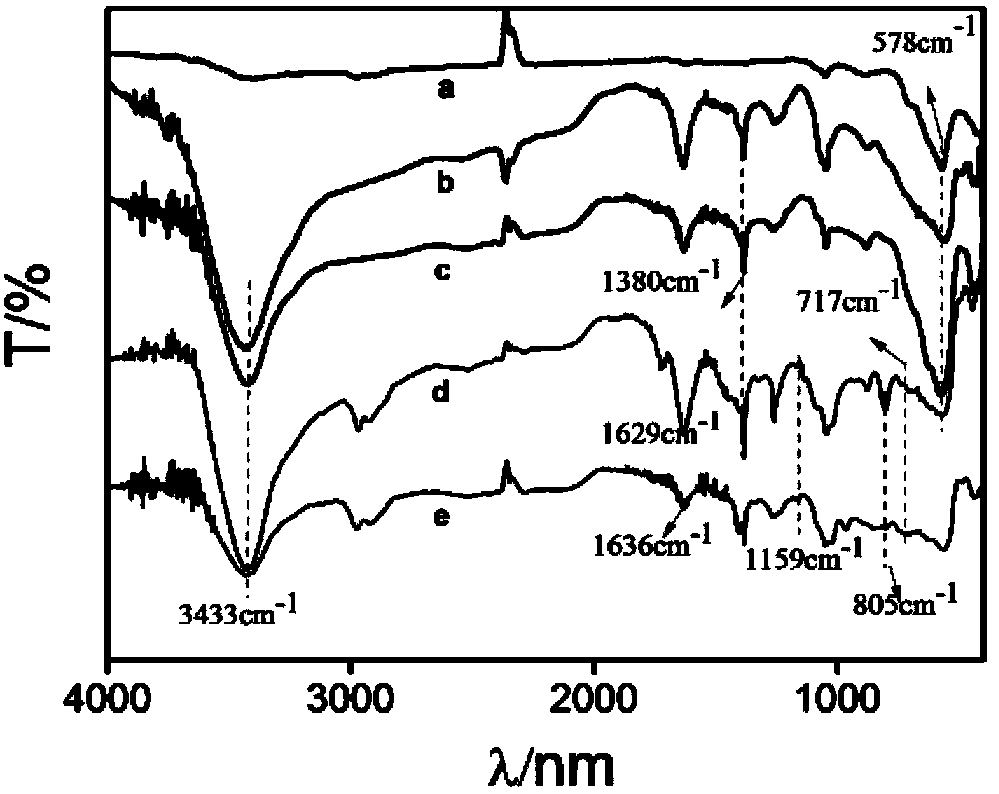

[0026] (1) Fe 3 o 4 Preparation of NPs: 2.35g FeSO 4 ·7H 2 O and 4.1 g FeCl 3 ·6H 2 O was dissolved in 90mL of water, and 25mL of ammonia water with a concentration of 25% by mass was quickly added at room temperature, the solution turned from orange to black, and then 1mL of oleic acid was added dropwise, and then Under the reaction for 1h, Fe with an average particle size of 6-7nm was obtained 3 o 4 NPs. The above experimental process needs to be carried out under the protection of nitrogen. Finally, the Fe in the solution is 3 o 4 NPs were isolated and stored at 4°C for future use;

[0027] (2) Preparation of magnetic molecularly imprinted polymer: 50mg Fe 3 o 4 Dissolve NPs in 20mL, 10mM, pH8.0 Tris buffer solution, add 5mL acetonitrile solution containing 1mg / mL CPF, mechanically stir for 2h at room temperature, then add 25mg DA, continue stirring for 4h at room temperature; the reaction product is separated by a magnet , the imprinted CPF molecules and unpo...

Embodiment 2

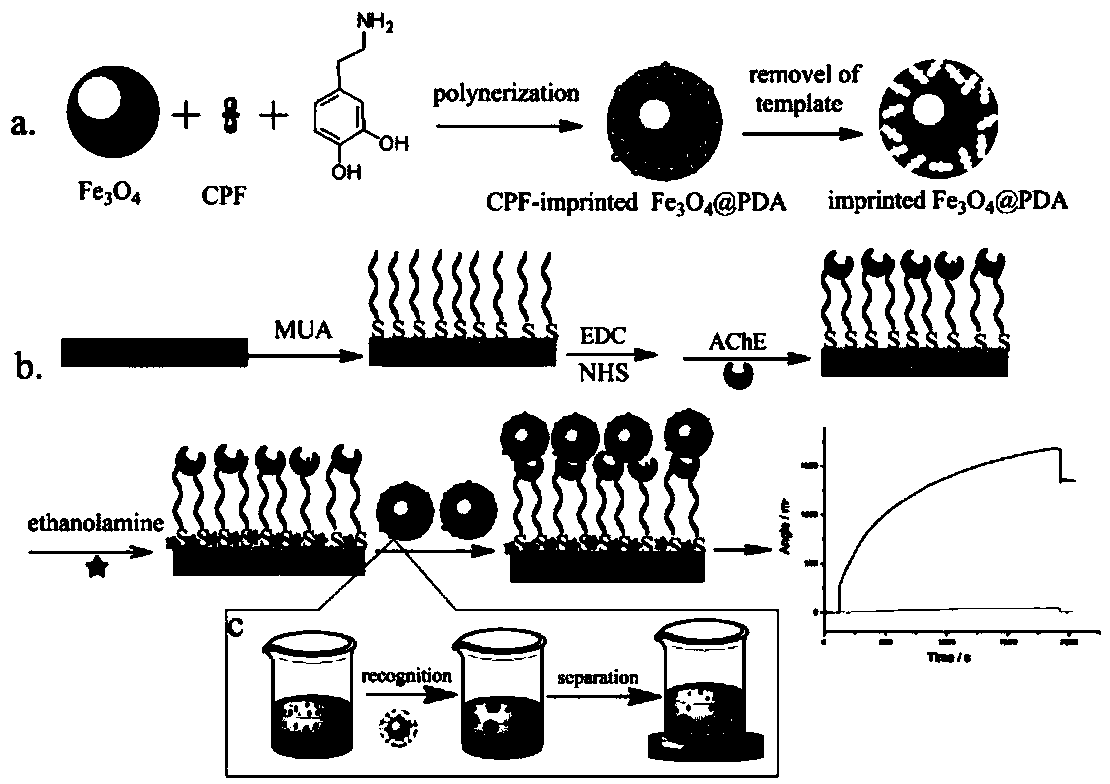

[0032] Construction of SPR sensing interface

[0033] (1) The construction process of the SPR sensing interface is as follows: figure 1 shown. First place the gold flakes in H with a volume ratio of 7:3 2 SO 4 :H 2 o 2 Soak in the mixed solution for 2 minutes, rinse with secondary water and blow dry with nitrogen, and install it into the SPR detection cell. Inject 50 μL of 1 mM 11-mercaptoundecanoic acid solution into the detection cell to react for 2 hours, rinse with secondary water, inject 50 μL of 0.2M 1-ethyl-3-(3-dimethylaminocarbodiimide) hydrochloride and 0.05M N-hydroxysuccinimide mixed solution was reacted for 10 minutes, and then injected with 50 μL 2U / mL AChE solution for 30 minutes; finally, 50 μL of 1.0M ethanolamine solution was injected for 10 minutes, and after washing with 10 mM Tris buffer solution of pH 8.5, the AChE functional Optimized SPR sensing interface;

[0034] (2) Combining CPF with MIP-Fe 3 o 4 PDA NPs were mixed at room temperature and i...

Embodiment 3

[0037] (1) Influence of polymerization time, pH of polymerization solution, and pH of recombination medium solution on sensor performance

[0038] Image 6 A is the effect of DA aggregation time on sensor performance. It can be seen from the figure that as the polymerization time prolongs, the SPR angle change (ΔAngle) gradually increases. When the polymerization time is 4h, ΔAngle reaches the maximum, and after more than 4h, ΔAngle decreases. If the polymerization time is too short, the number of imprinted sites is small, resulting in weak adsorption capacity for CPF; if the polymerization time is too long, the thickness of the PDA film will be large, and the elution efficiency of CPF will be low, which will lead to a decrease in the adsorption capacity of molecular imprinting. Therefore, the best polymerization time for choosing DA is 4h. Image 6 B is the effect of the pH of the polymerization solution on the performance of the sensor. Lower pH will inhibit the self-poly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com