Method for preparing tissue engineering cell culture support

A cell culture and tissue engineering technology, applied in the field of tissue engineering cell culture scaffolds, can solve the problems of difficult to increase porosity, insufficient manufacturing process, high cost, etc., to achieve improved biocompatibility, excellent mechanical properties, good biological compatibility effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

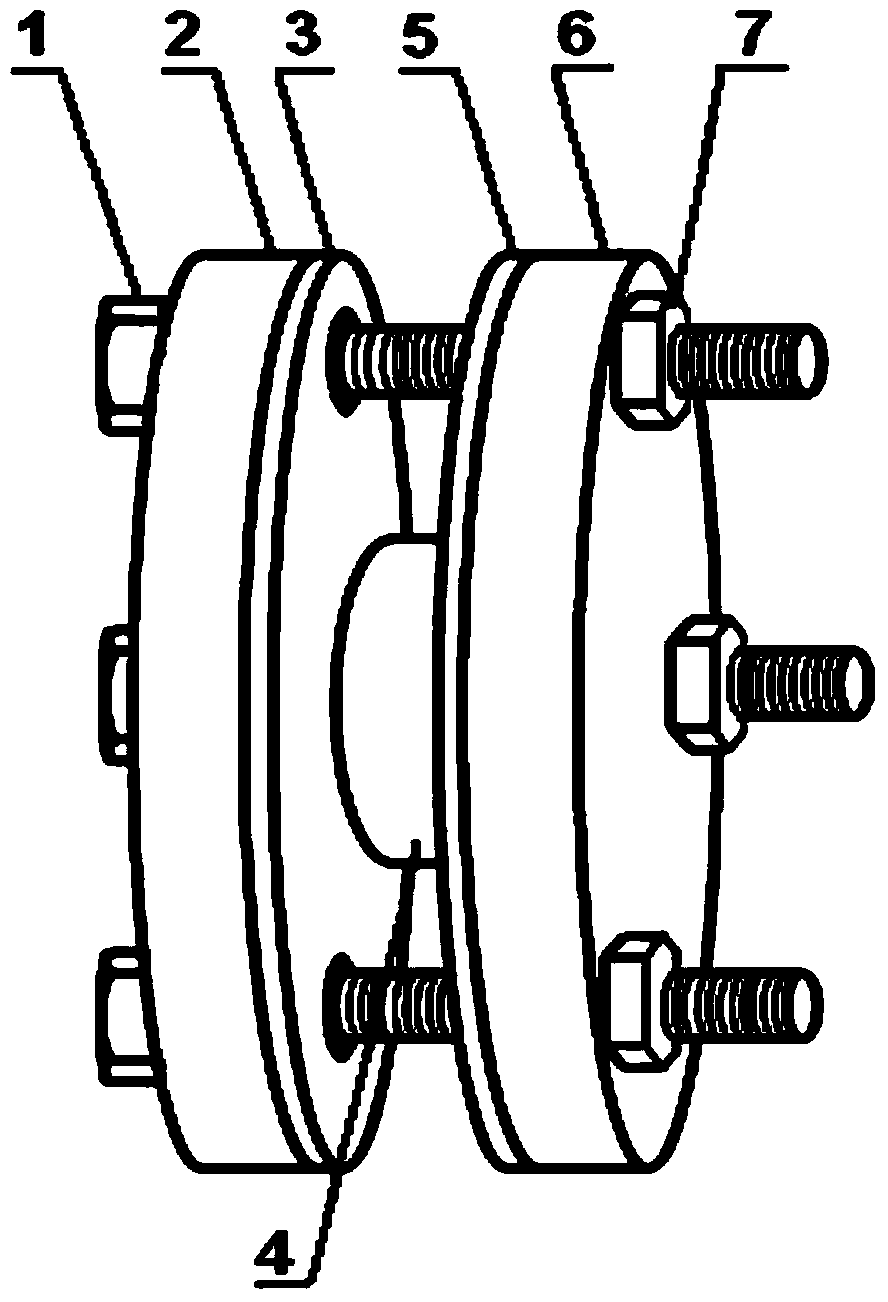

Embodiment 1

[0051] Take 1.0 g of 316L stainless steel fiber with a diameter of 30 μm, cut it into short fibers with a length of 5 mm, fill it randomly into a barrel-shaped mold with an inner diameter of 20 mm, and press it from above with a rod-shaped indenter, according to the design porosity 90% and the thickness of the preform is 4 mm to obtain a cylindrical cell culture scaffold preform with a thickness of 4 mm. Put the cylindrical cell culture scaffold preform obtained after pressing into oxalic acid aqueous solution (5% W / V), acetone, absolute ethanol and deionized water for ultrasonic cleaning, each ultrasonic cleaning for 10 minutes. Then, the preform was put into a vacuum drying oven at a temperature of 60° C. and kept at a constant temperature for 2 hours. Next, clamp the prefabricated body into the disc-type pressurizing device, adjust the nut to tighten the pressing piece to keep the thickness of the preformed body at 4mm, and place the disc-type pressurizing device with the p...

Embodiment 2

[0053] Take 1.0 g of 316L stainless steel fiber with a diameter of 30 μm, cut it into short fibers with a length of 5 mm, and then evenly disperse and fill it in a barrel-shaped mold with an inner diameter of 20 mm, and press it with a rod-shaped indenter. According to the design porosity 80% and a preform thickness of 2mm are pressed to obtain a cylindrical cell culture scaffold preform with a thickness of 2mm. . Put the cylindrical cell culture scaffold preform obtained after pressing into oxalic acid aqueous solution (5% W / V), acetone, absolute ethanol and deionized water for ultrasonic cleaning, each ultrasonic cleaning for 10 minutes. Then, the preform was put into a vacuum drying oven at a temperature of 60° C. and kept at a constant temperature for 2 hours. Next, clamp the prefabricated body into the disc-type pressurizing device, adjust the nut to tighten the pressing piece to keep the thickness of the preformed body at 2mm, and place the disc-type pressurizing device...

Embodiment 3

[0055] Take 1.0g of 316L stainless steel fiber with a diameter of 30μm, integrate it into a bundle, bend it into a "Z"-shaped fiber bundle with a total length of 15mm, and cut it (the "Z"-shaped fiber bundle is bent twice The final three fiber bundles are formed, each length is equal to 5mm), and then the "Z"-shaped fiber bundles with equal lengths are dispersed into a single "Z"-shaped fiber and then randomly placed in a conical container to form a structure , and then fill this structure in a barrel-shaped mold with an inner diameter of 20 mm. According to the design porosity of 90% and the prefabricated body thickness of 4 mm, the prefabricated body of the cylindrical cell culture scaffold with a thickness of 4 mm is obtained. Put the cylindrical cell culture scaffold preform obtained after pressing into oxalic acid aqueous solution (5% W / V), acetone, absolute ethanol and deionized water for ultrasonic cleaning, each ultrasonic cleaning for 20 minutes. Then, the preform wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com