Glazed tile produced by waste materials of red bricks, and producing method thereof

A glazed tile and waste technology, which is applied in the field of using red brick waste to produce glazed tiles, can solve the problems of changing the color of the green body, limited application, and pinholes in the green body, and achieves a simple recycling process, reducing production costs, and stabilizing materialization. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-5

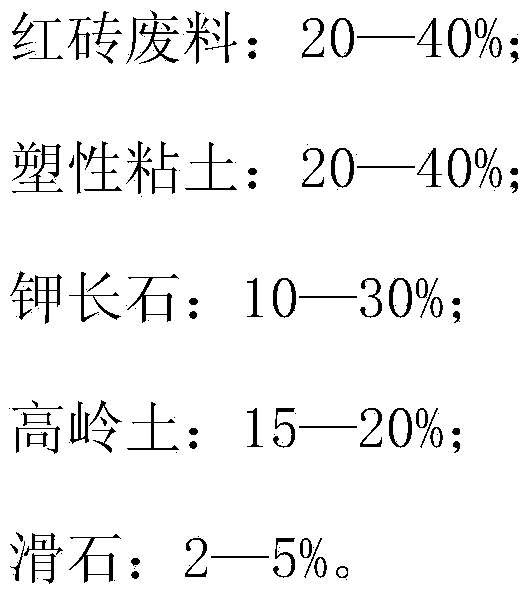

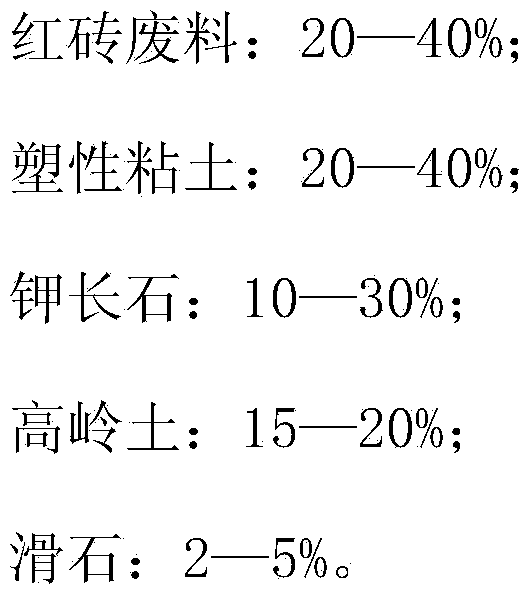

[0026] In the following examples, the main chemical components of the building red brick waste selected in the raw materials are: silicon dioxide 72.03%, aluminum oxide 15.13%, ferric oxide 6.10%, potassium oxide 2.26%, loss on ignition 0.97%, and the rest The composition is undetermined; the plastic clay is yellow clay, and its main chemical composition is: silicon dioxide 71.81%, aluminum oxide 14.5%, ferric oxide 4.17%, potassium oxide 2.96%, loss on ignition 4.14%, and other components is undetermined. Those of ordinary skill in the art should understand that the chemical components given here are exemplary, and the chemical components of building red brick waste and plastic clay in different regions will have certain differences, but the content of ferric oxide in the building red brick waste ≥ 5%.

[0027] After the red brick waste is cleaned, it is crushed with a jaw crusher, and the particles with a particle size of less than 5cm are selected and put into the homogeni...

Embodiment 6

[0043] Because the printing layer is not wear-resistant more, for this reason, the present invention provides following embodiment 6

[0044] The formula and process as in Example 3 are selected, the difference is that after inkjet printing, a layer of transparent or translucent glaze is applied to form a surface glaze layer.

[0045] In this example, the formula of the selected surface glaze layer glaze is: glaze powder 85%, transparent frit 10%, kaolin 5%, wherein the chemical composition of glaze powder is: silicon dioxide 47.34%, oxide Aluminum 20.16%, ferric oxide 0.18, titanium dioxide 0.23, calcium oxide 10.30%, magnesium oxide 4.50%, potassium oxide 1.25%, sodium oxide 3.37%, barium oxide 2.23, zinc oxide 1.28, zirconium oxide 1.49, loss on ignition 7.67% , Moreover, the glaze with the above ratio can make the ceramic inkjet printing ink better in color and make the printing pattern more gorgeous. Glazing thickness is 0.01-0.1mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com