Preparation method of hexaphenoxycyclotriphosphazene (HPCTP)

A technology of hexaphenoxy cyclotriphosphazene and phenol, which is applied in the field of preparation of hexaphenoxy cyclotriphosphazene, can solve the problems of complicated operation, large pollution, high experiment risk and the like, and achieves simple process flow and high production efficiency. High rate and high purity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

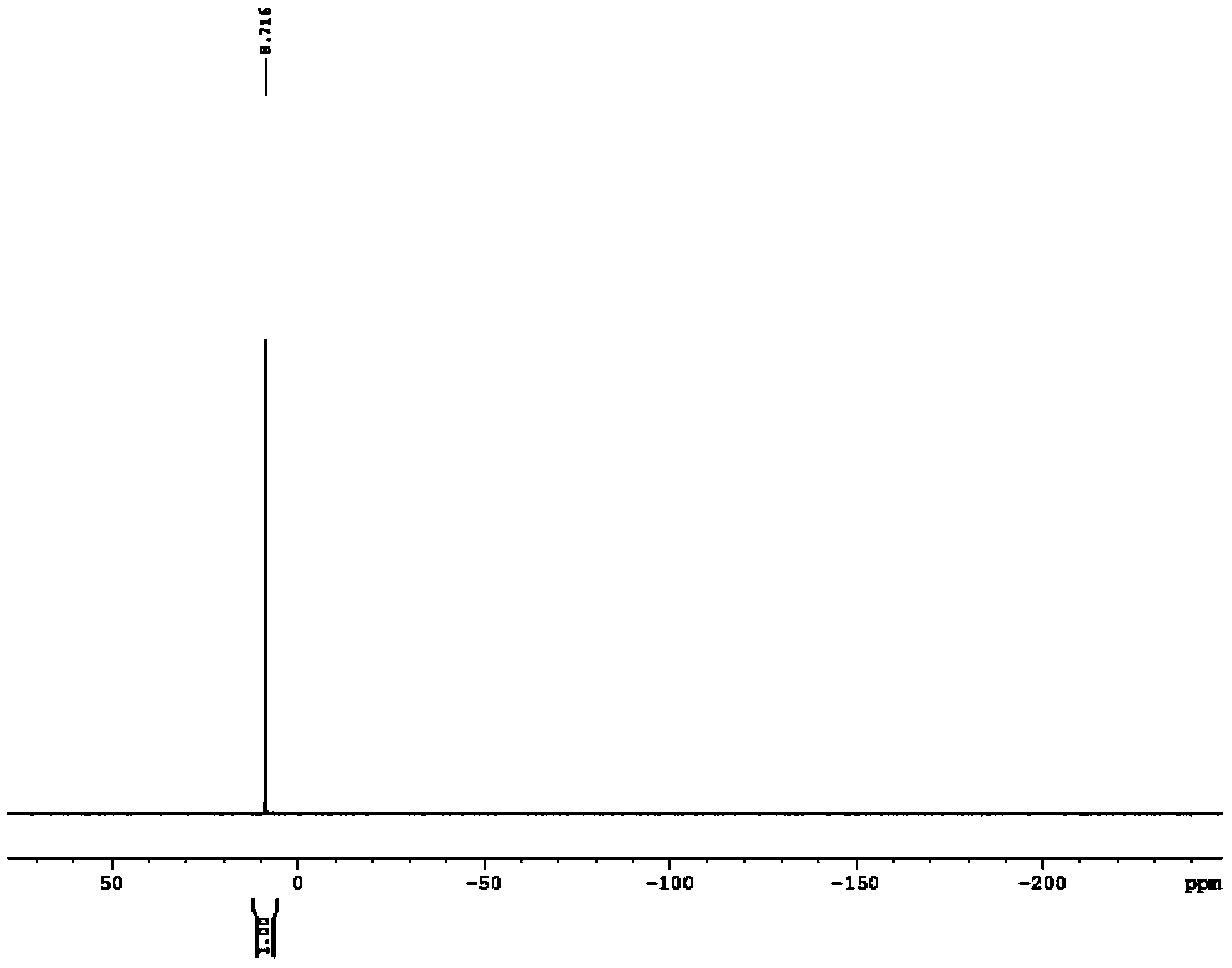

[0036] A preparation method for hexaphenoxy cyclotriphosphazene, comprising the following steps:

[0037] 1) Evenly disperse phenol and alkali metal hydroxide in methanol, and reflux reaction under the protection of inert gas for 0.5-2h;

[0038] 2) remove the methanol solvent and recover, and dry the obtained product after cooling;

[0039] 3) Put the product phenate and ketone solvent obtained in the previous step in the reaction kettle, and then add the ketone solution of hexachlorocyclotriphosphazene dropwise into the reaction kettle;

[0040] 4) Reflux reaction for 4-48h;

[0041] 5) After the reaction, the solvent is removed and recovered;

[0042] 6) Add deionized water to the reaction kettle, stir to make the product evenly dispersed, release the material and centrifuge, and repeat washing until the filtrate is neutral;

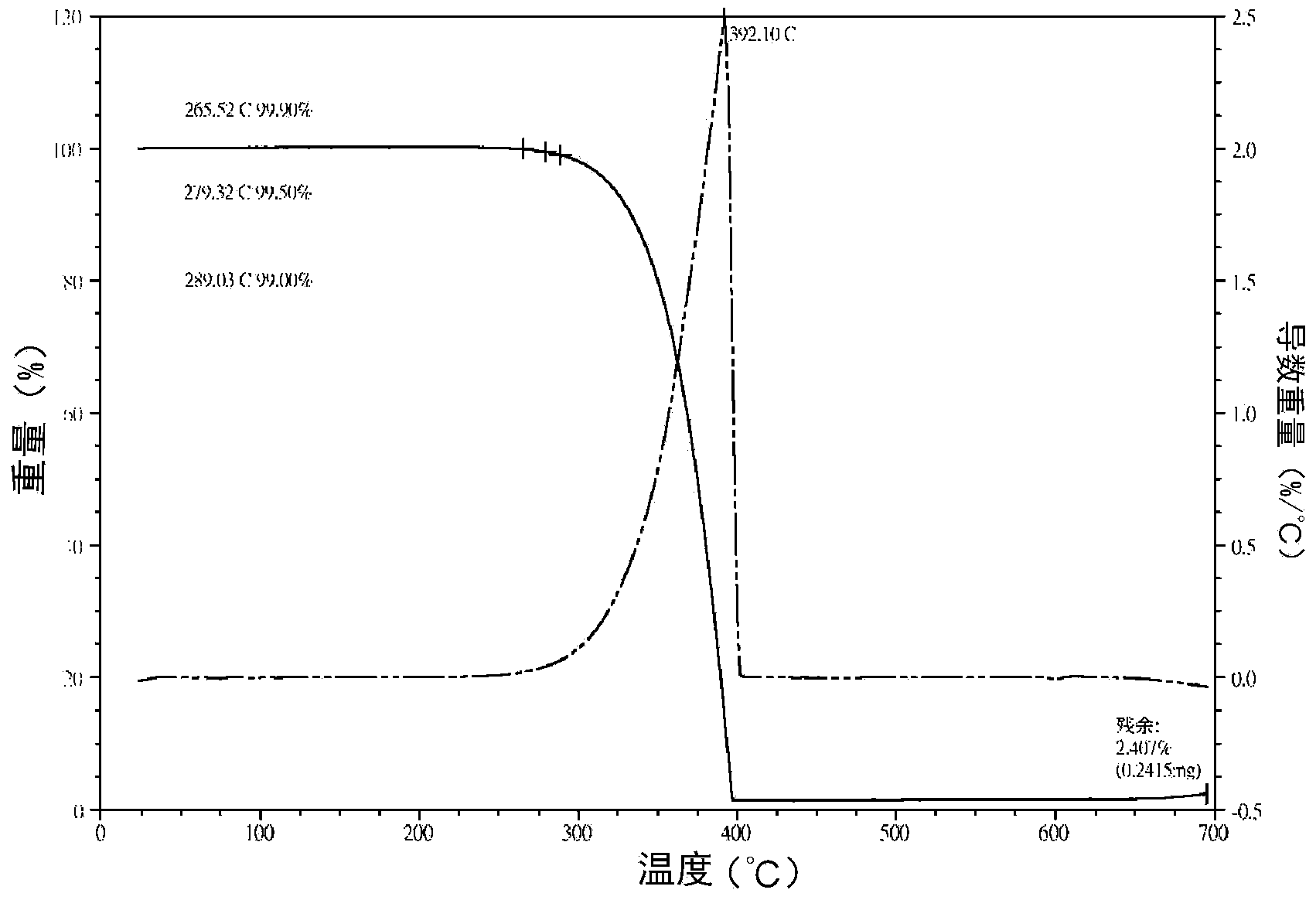

[0043] 7) Dry the product obtained in the previous step to obtain a crude product;

[0044] 8) Heat the crude product and alcohol solvent to 70-7...

Embodiment 1

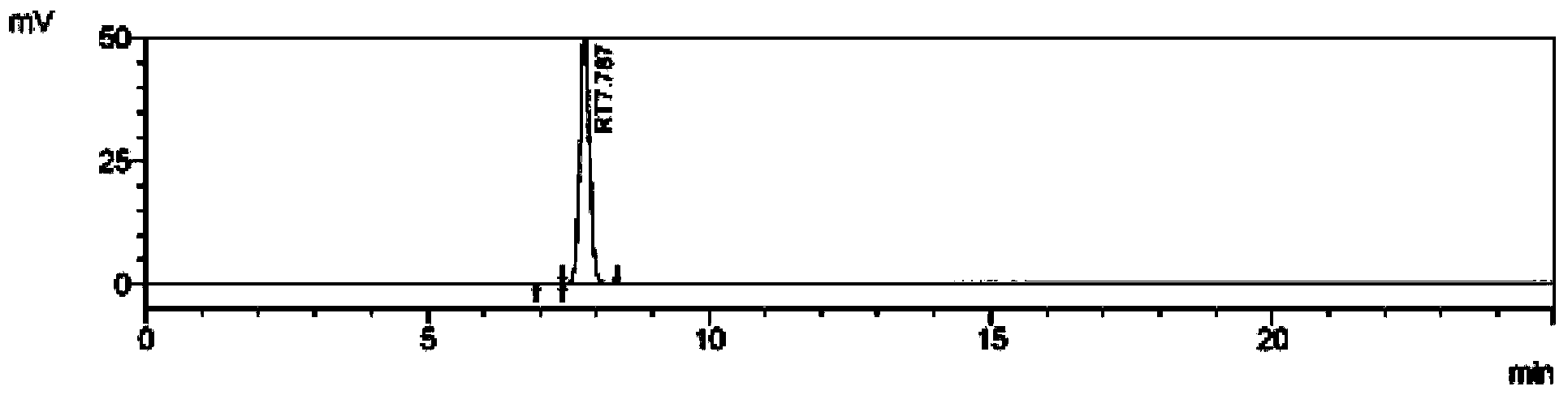

[0057] Add 67.76g of phenol and 250mL of methanol to a 500mL four-necked flask equipped with a stirring, reflux and nitrogen protection device and stir evenly, then add 28.81g of sodium hydroxide, heat up to reflux for 1 hour, and distill part of it under reduced pressure ( 60-80%, the distilled methanol is 60-80% of the original added methanol) methanol is recovered, cooled and filtered to obtain sodium phenate solid, put in a 100°C oven for drying for 2 hours, and weighed to obtain 81.88g of sodium phenate. The rate is 98%.

[0058] In the 1L four-neck flask with stirring and reflux device, add above-mentioned sodium phenate 80g and acetone 50mL, after stirring evenly, add 200mL acetone solution containing 33.30g of hexachlorocyclotriphosphazene, which contains hexachlorocyclotriphosphazene The time for adding the acetone solution is 3.5 hours, keep the system temperature at 50-55°C, then start heating, react under reflux for 30 hours, distill under reduced pressure, distill...

Embodiment 2

[0060] Add 75.32g of phenol and 250mL of methanol into a 500mL four-necked flask equipped with a stirring, reflux and nitrogen protection device and stir evenly, slowly add 33.60g of sodium hydroxide, heat up to reflux for 1 hour, and distill off part (60-80% ) methanol and recovered, cooled and filtered to obtain sodium phenate solid, put it in an oven at 100°C for 2 hours, and weighed to obtain 91.91 g of sodium phenate, with a yield of 99.0%.

[0061] In a 1L four-necked flask with a stirring and reflux device, add the above-mentioned sodium phenate 85g and acetone 50mL, stir well and add 200mL of acetone solution containing 34.77g of hexachlorocyclotriphosphazene, which contains hexachlorocyclotriphosphazene The time for adding the acetone solution is 5 hours, keep the temperature of the system at 50-55°C, then start heating, react under reflux for 20 hours, distill under reduced pressure, distill all the acetone out and recover it, add 800mL deionized water into the four-n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com