Polarizing plate and liquid crystal display device

A polarizer and polarizing film technology, applied in polarizing components, instruments, optics, etc., can solve problems such as insufficient ultraviolet absorption performance, and achieve excellent ultraviolet absorption performance, excellent durability, and excellent environmental resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

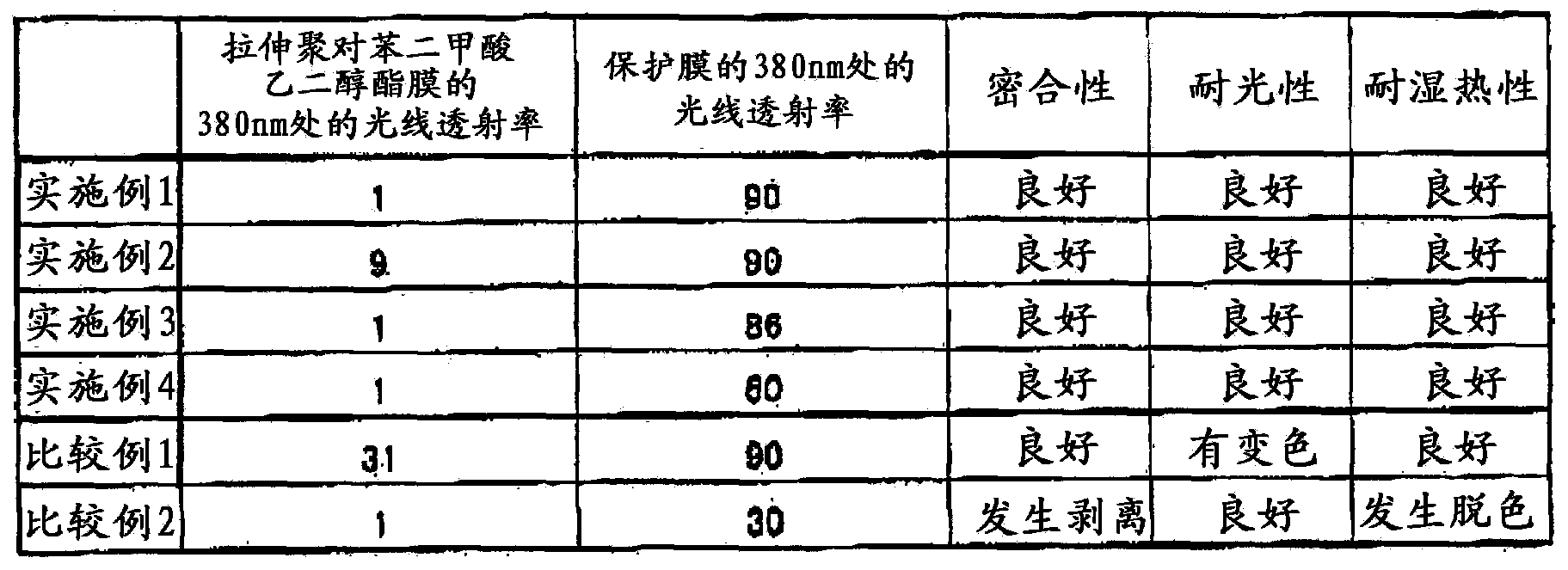

[0205] Hereinafter, the present invention will be described in more detail by way of examples, but the present invention is not limited to these examples. In addition, the % and the part which show content or usage-amount in these examples are based on weight unless otherwise indicated. The evaluation was performed as follows.

[0206]

[0207] About the protective film laminated|stacked on the polarizing film, the light transmittance of 320mn and 380mn was measured using the spectrophotometer UV2450 by Shimadzu Corporation.

[0208]

[0209] The obtained polarizing plate was cut into 40 mm×40 mm, and was bonded to a glass substrate via an adhesive on the outer surface of the protective film laminated on the opposite side to the stretched polyethylene terephthalate film. Then, Sunshine Weather Meter (S80 by Suga Test Instruments Co., Ltd.) was put in so that the stretched polyethylene terephthalate film was irradiated with ultraviolet rays. After 500 hours of irradiation...

manufacture example 1

[0214] [Production Example 1] Production of polarizing film

[0215] A polyvinyl alcohol film having an average degree of polymerization of about 2400, a degree of saponification of 99.9 mol% or more, and a thickness of 75 μm was immersed in pure water at 30°C, and then immersed in iodine / potassium iodide / pure water at a weight ratio of 0.02 / 2 / 100 at 30°C. in aqueous solution. Then, it was immersed in an aqueous solution having a weight ratio of potassium iodide / boric acid / pure water of 12 / 5 / 100 at 56.5°C, followed by washing with pure water at 8°C, and drying at 65°C to obtain iodine-adsorbed and oriented polymers. Polarizing film for vinyl alcohol. The stretching was mainly performed in the steps of iodine dyeing and boric acid treatment, and the total stretching ratio in the steps was 5.3 times.

manufacture example 2

[0216] [Production Example 2] Production of UV-curable Adhesive Composition

[0217] The following components were mixed to prepare a liquid adhesive composition.

[0218] 3,4-Epoxycyclohexylmethyl 3,4-epoxycyclohexanecarboxylate 40 parts

[0219] Bisphenol A epoxy resin 60 parts

[0220] Diphenyl[4-(phenylthio)phenyl]thio Hexafluoroantimonate (cationic polymerization initiator)

[0221] 4.0 servings

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com