Bisphenol epoxy resin and preparation method thereof

A bisphenol epoxy resin, phenol technology, applied in the chemical field, can solve the problems of low heat resistance and toughness, poor heat and humidity resistance and weather resistance, and achieve low cost, good toughness and heat and humidity resistance, and improved toughness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

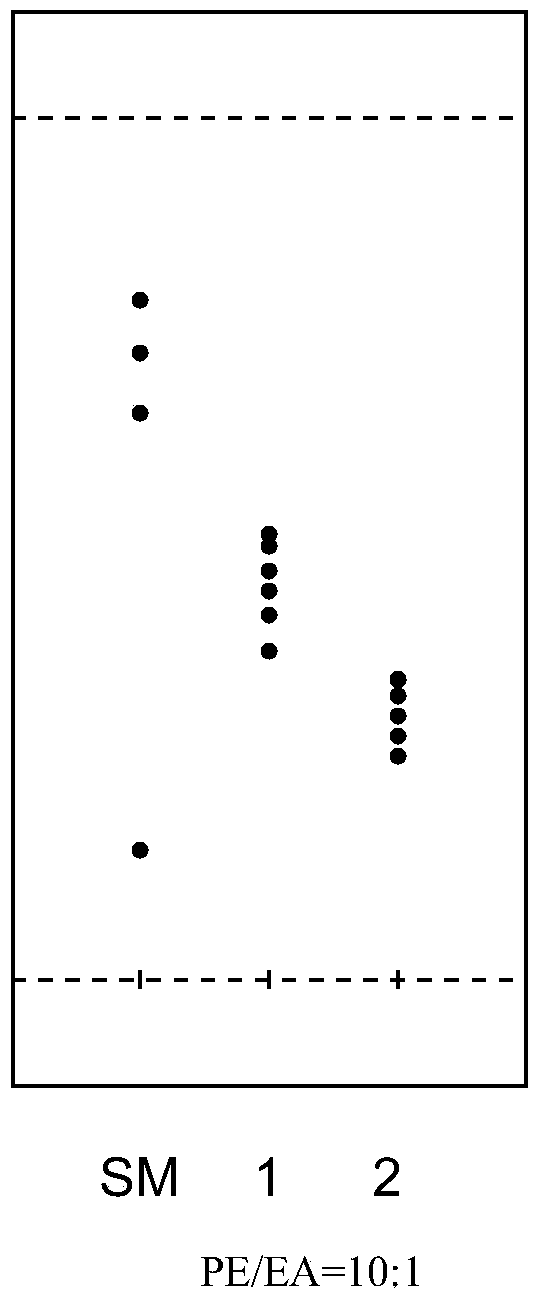

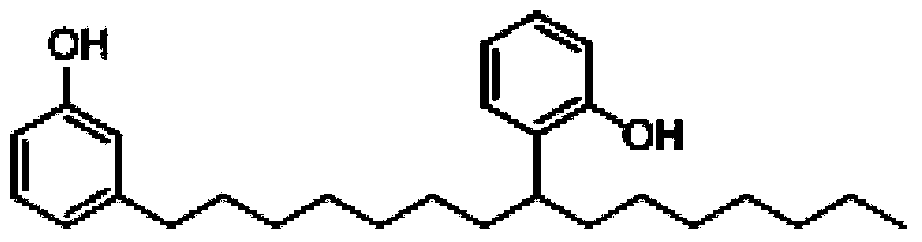

[0051] The invention provides a preparation method of bisphenol as raw material of epoxy resin. According to the molar ratio of cardanol:phenol = 1:1-10, the catalyst is added into the four-necked flask according to the amount of 0.02-10% of the amount of cardanol, nitrogen Under protection, heat to 70-160°C and stir for 1-10 hours, then discharge, dilute with xylene, wash with hot water (80°C, 500mL*5-10), remove excess phenol, evaporate xylene phase solvent in vacuum The yellow-brown viscous liquid is cardanol-phenol adduct. The viscosity is 8000-150000mPa.S. The compound was separated by column chromatography (silica gel 100-200 mesh, benzene as the eluent) to separate two groups of structures (component 1 and component 2), and then identified by NMR:

[0052] Depend on figure 2 It can be seen that new substances are generated through the reaction. Due to the complexity of the components, the column chromatography cannot be completely separated, so they are divided into t...

Embodiment 2

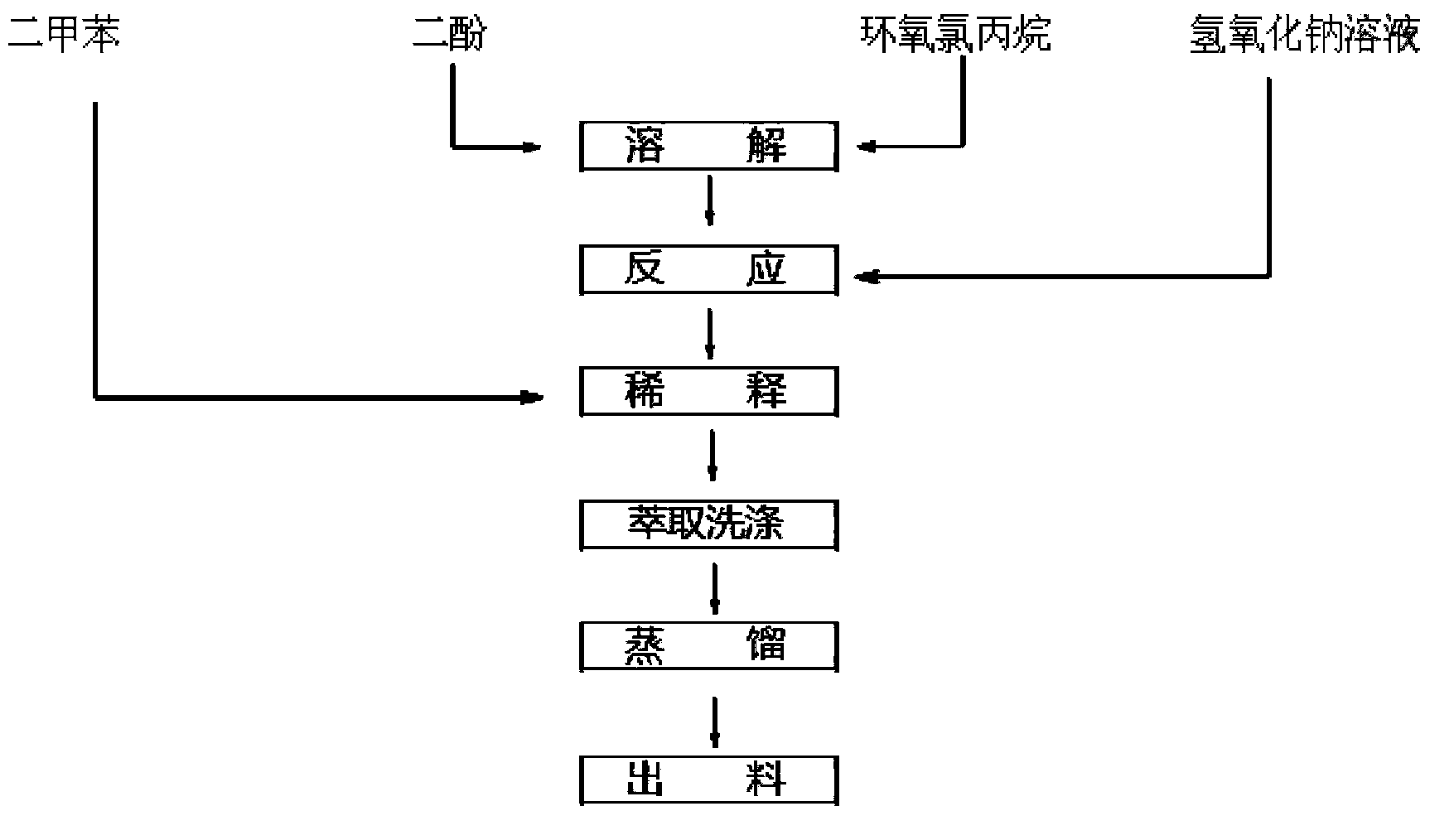

[0060] like figure 1 As shown, the present invention provides a kind of preparation method of bisphenol epoxy resin, according to bisphenol: epichlorohydrin: the mol ratio of sodium hydroxide=1:1.5~10:1.5~10 quality weighs each material, Then add bisphenol into the reaction vessel, stir, pass nitrogen gas to discharge the air, add epichlorohydrin after 1 to 5 minutes, continue stirring, control the temperature at 40-50 degrees Celsius, add sodium hydroxide, the said hydroxide The mass percentage concentration of sodium is 30-50%. After the dropwise addition, the temperature is raised to 70-100 degrees Celsius, kept for 2-9 hours, dissolved in xylene, washed with hot water for many times, and then distilled under reduced pressure to obtain the first batch of brown-red products. The viscous liquid is the prepared product. The bisphenol used in this embodiment is the bisphenol mixture obtained in Example 1.

[0061] The obtained epoxy resin was basically detected, the epoxy val...

Embodiment 3

[0063] Embodiment 3 The curing experiment of bisphenol epoxy resin and MD650 curing agent.

[0064] The general preparation method of the paint film is in accordance with the national standard GB1727-79, the pencil hardness test method GB / T6739-1996, the paint film adhesion test method GB1720-79, the paint film flexibility test method (bending) GB1731-1993, the paint film impact resistance test Method GB1732-93, plastic Shore hardness test method GB-T2411-2008.

[0065] project

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy value | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com