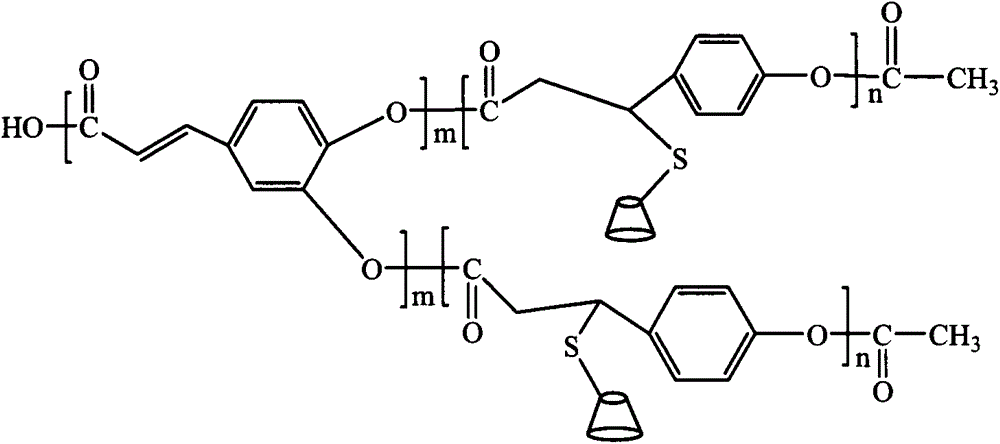

A photosensitive cyclodextrin polymer and its nanoparticles

A cyclodextrin polymer and nanoparticle technology is applied in the field of functional polymer materials to achieve good photosensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] Embodiment 1, sulfonylated β-cyclodextrin (6-OTs-β-CD)

[0014] Add 50g (44mmol) of β-CD to 1L of water dissolved with 16g (400mmol) of NaOH, stir vigorously in an ice bath at 0°C, and slowly add 36g (187mmol) of p-toluenesulfonyl chloride (TsCl) to the system, resulting in a white Precipitation, reaction at 0 ° C for 2h. The insoluble matter was removed by suction filtration, and the pH of the filtrate was adjusted to 7.0 with 10% HCl by volume. The precipitate was recrystallized with deionized water and dried in vacuo to obtain monosulfonylated β-CD (6-OTs-β-CD).

Embodiment 2

[0015] Example 2, thiolated β-cyclodextrin (6-SH-β-CD)

[0016] Add 12g (9.3mmol) 6-OTs-β-CD and 12g (158mmol) thiourea into 480mL anhydrous DMF, and react at 75°C for 48h. After the reaction, cool to room temperature. Then add 1.4L of anhydrous ether and stir, the precipitate is filtered, and washed twice with acetone. The resulting product and 480mg Na 2 S 2 o 5 Dissolve in 400ml of 1mol / L NaOH and stir at room temperature for 30min. Acidify with 1mol / L HCl to pH = 3, then add 20mL trichlorethylene, and sonicate for 10min. The precipitate is filtered, recrystallized twice with water, and dried to obtain 6-SH-β-CD, which is a white powder.

Embodiment 3

[0017] Embodiment 3, poly 3,4-dihydroxycinnamic acid (PDHCA)

[0018] Add 43g (239mmol) of DHCA and 4g (48.8mmol) of sodium acetate into 100mL of acetic anhydride, pass through N2, react at 140°C for 1h, and at 200°C for 6h. The obtained product was washed twice with ethanol and deionized water twice, and dried at 50° C., and the obtained product was a brown powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com