Method for preparing paricalcitol

A technology of paricalcitol and chemical reaction, which is applied in the field of 1-α-hydroxy-19-desmethylene vitamin D2, a drug for treating osteoporosis, can solve the problem that paricalcitol is uneconomical and has many steps. , complex operation and other problems, to achieve the effect of improving yield, simplifying process flow, and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

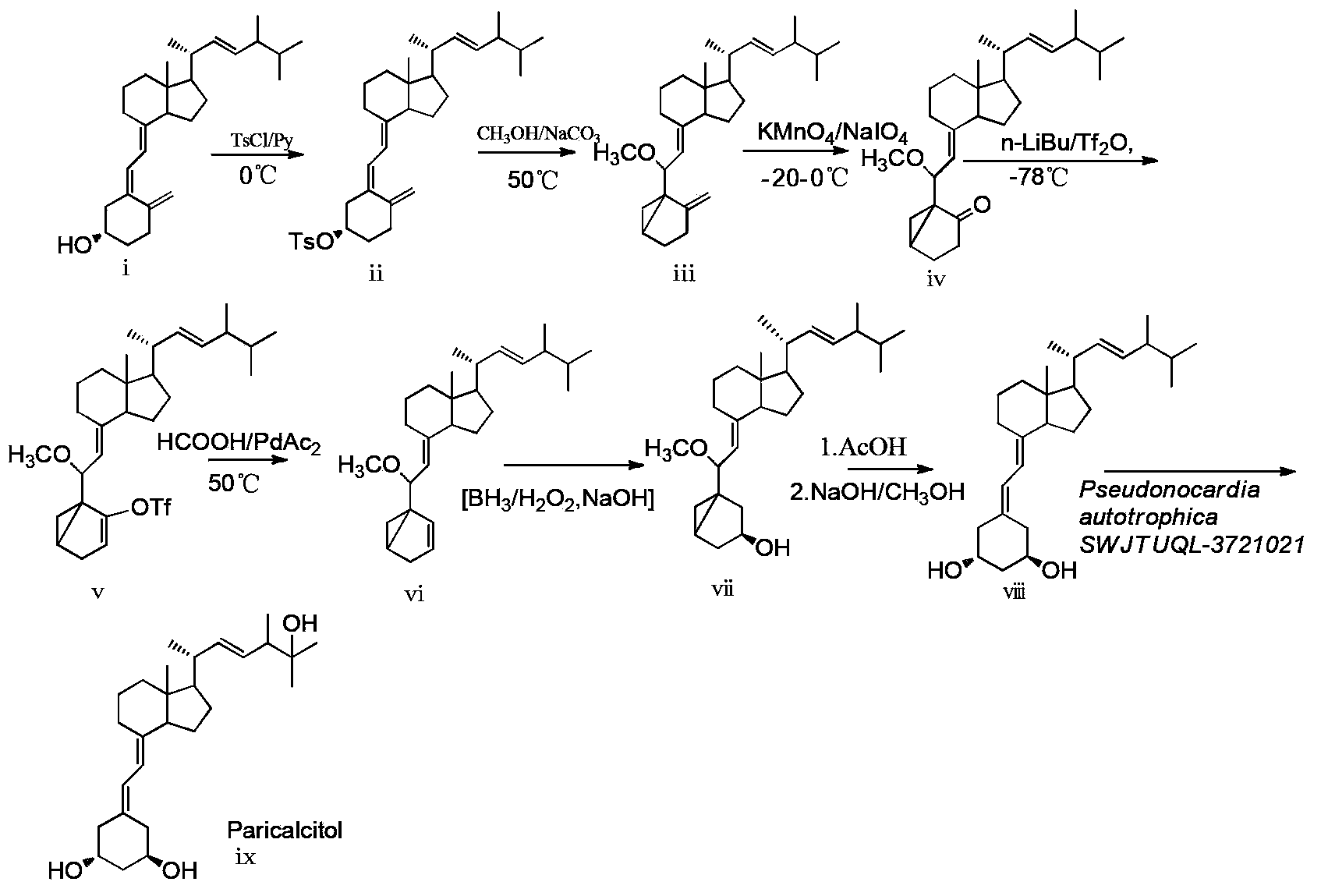

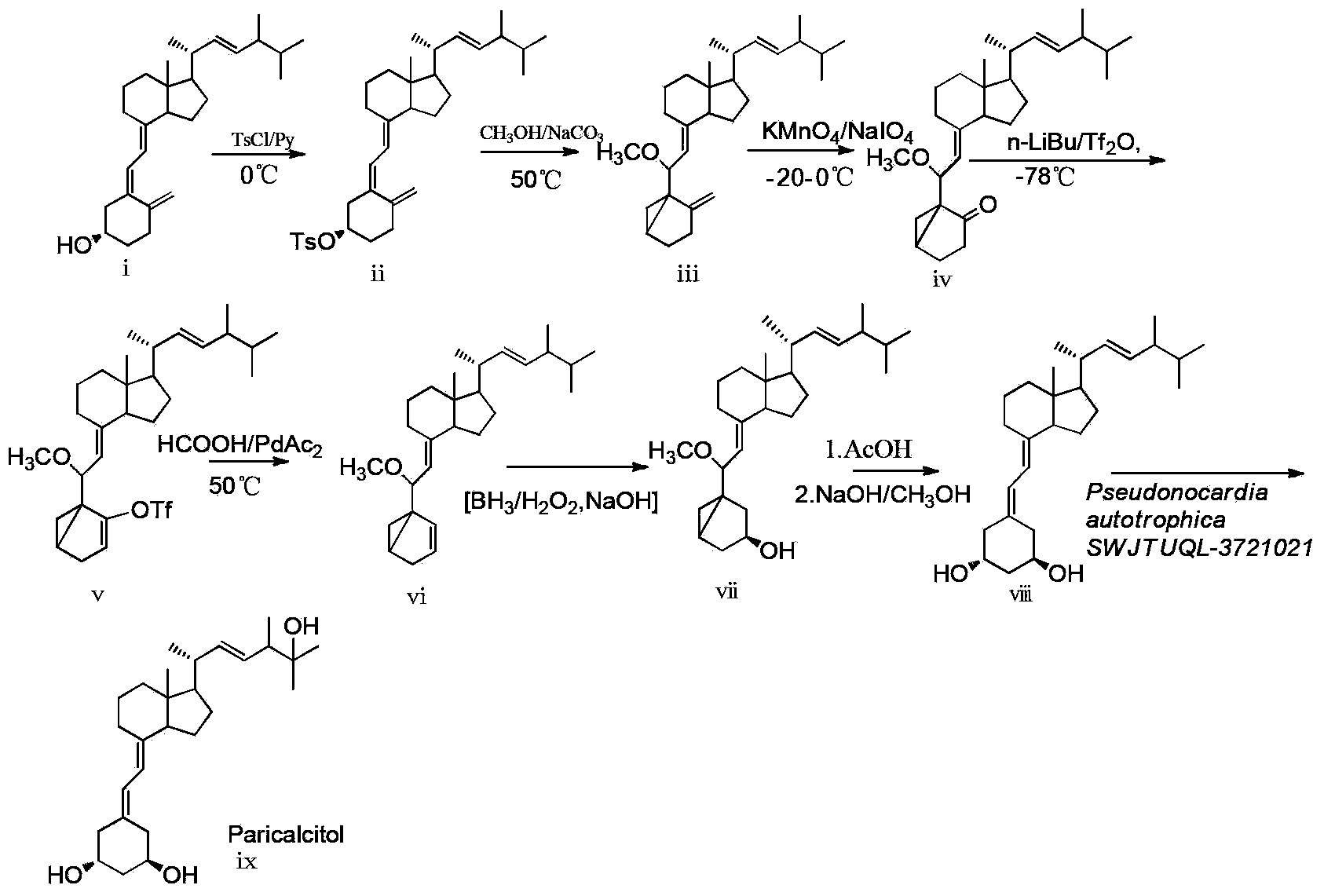

[0034] 1-Hydroxy-19-norvitamin D 2 (ⅷ) Preparation

[0035] a) 10-oxo-3,5-cyclovitamin D 2 (ⅳ) synthesis

[0036] 3,5-cyclovitamin D 2 (Ⅲ) was synthesized using the method of DeLuca et al. (US4195027) to synthesize vitamin D 2 Converted to 3,5-cyclized vitamin D 2 (Ⅲ), add 3.88g, 9.46mmol) 3,5-cyclovitamin D in the reaction flask 2 , dissolved in 300ml ethanol, cooled to -20°C, and then dropwise added potassium permanganate solution (KMnO 4 3.33g, H 2 O100ml), about 20 minutes. Stir at this temperature for 1 h, and then stir for 15 min in a water bath at 40 °C. After filtration, the filtrate was concentrated to dryness under reduced pressure to obtain light yellow oily mixture 4 (3.67g). The crude product was dissolved in 300ml of ethanol, 100ml of saturated sodium periodate was added, and stirred at room temperature for 2.5h. The reaction solution was extracted with ethyl acetate (2×200ml) and washed with saturated sodium chloride solution (1×200ml). The organic lay...

Embodiment 2

[0042] a) 10-oxo-3,5-cyclovitamin D 2 (ⅳ) synthesis

[0043] 3,5-cyclovitamin D 2 (Ⅲ) was synthesized using the method of DeLuca et al. (US4195027) to synthesize vitamin D 2 Converted to 3,5-cyclized vitamin D 2 (iii), 3,5-cyclized VD 2 5 g, dissolved in 150 ml of ethanol, placed in a low-temperature bath at -20°C, and added dropwise with 3% KMnO 4(3% aqueous solution) 320 ml, after dripping, continue to react for 2 hours, timed TLC detection, after 3 hours, the raw materials are consumed, stir at 40°C for 15 minutes, solidify manganese dioxide, filter with diatomaceous earth, concentrate to remove alcohol, add ethyl acetate 100 ml of ester, extracted twice, concentrated to dryness, dissolved the crude product in 300 ml of ethanol, added 100 ml of saturated sodium periodate, and stirred at room temperature for 2.5 h. The reaction solution was extracted with ethyl acetate (2×200ml) and washed with saturated sodium chloride solution (1×200ml). The organic layer was dehydra...

Embodiment 3

[0049] 100ml of culture medium in a 500m shaker bottle, 1.5% glucose, 1.5% soybean cake powder, 0.5% corn steep liquor, 0.5% NaCl, 0.2% CaCO 3 , pH7.0. The medium was sterilized at 121°C for 20 minutes. Insert 2 ml of spore suspension of strain CGMCC5098, rotate at 27°C, rotate at 240rpm, cultivate for 4 days, 50mg 1-hydroxy-19-norvitamin D 2 (ⅷ) and 10 mg of β-cyclodextrin and 10 mg of Tween-80 were dissolved in 2 mL of ethanol, and the mixture was added to the culture medium, continued to cultivate for 3 days, filtered, and the filtrate was extracted with ethyl acetate 2×50 mL, and the extract Concentrate and separate with a silica gel column [column chromatography silica gel, ethyl acetate:petroleum ether (1:2)] to obtain 31 mg of the hydroxylated product Paricalcitol at position 25, with a yield of 60%. 1 H NMR (400MHz, CD 3 OD) δ6.21(d,1H,J=11Hz,H6),5.88(d,1H,J=11Hz,H7),5.35(dd,1H,J=8and15Hz,H23),5.27(dd,1H,J =8and15Hz,H22),4.04(m,1H,H1),3.98(m,1H,H3),2.84(brd,1H,J=11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com