Microparticle swarm fuel micro-combustion system based on digital holographic optical tweezers

A digital holographic and micro-particle technology, applied in the direction of burners, combustion methods, combustion types, etc., can solve the problems of shortened residence time, reduced combustion efficiency, and increased influence of the overall reaction, so as to improve the composition mode and increase the combustion efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

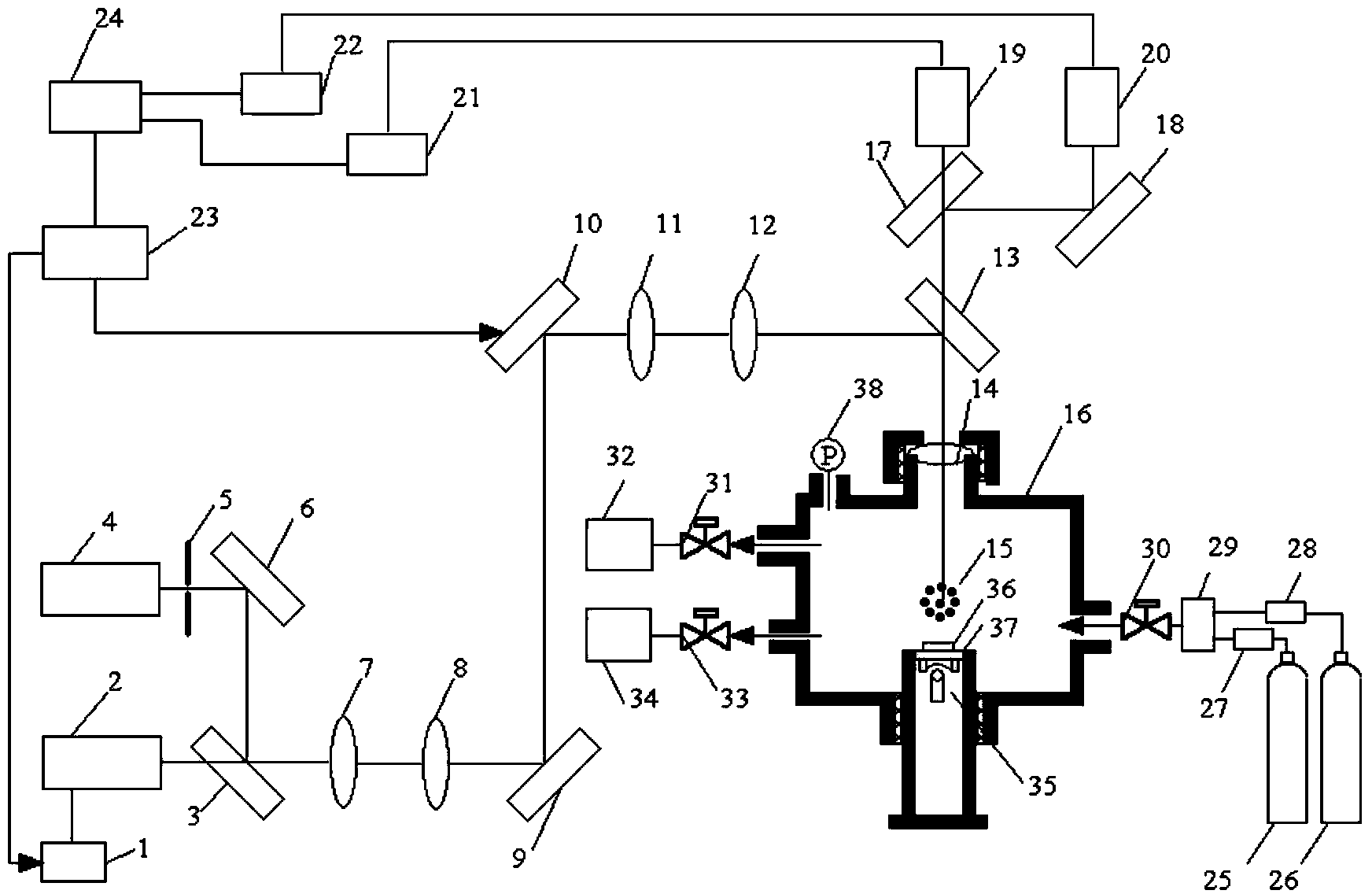

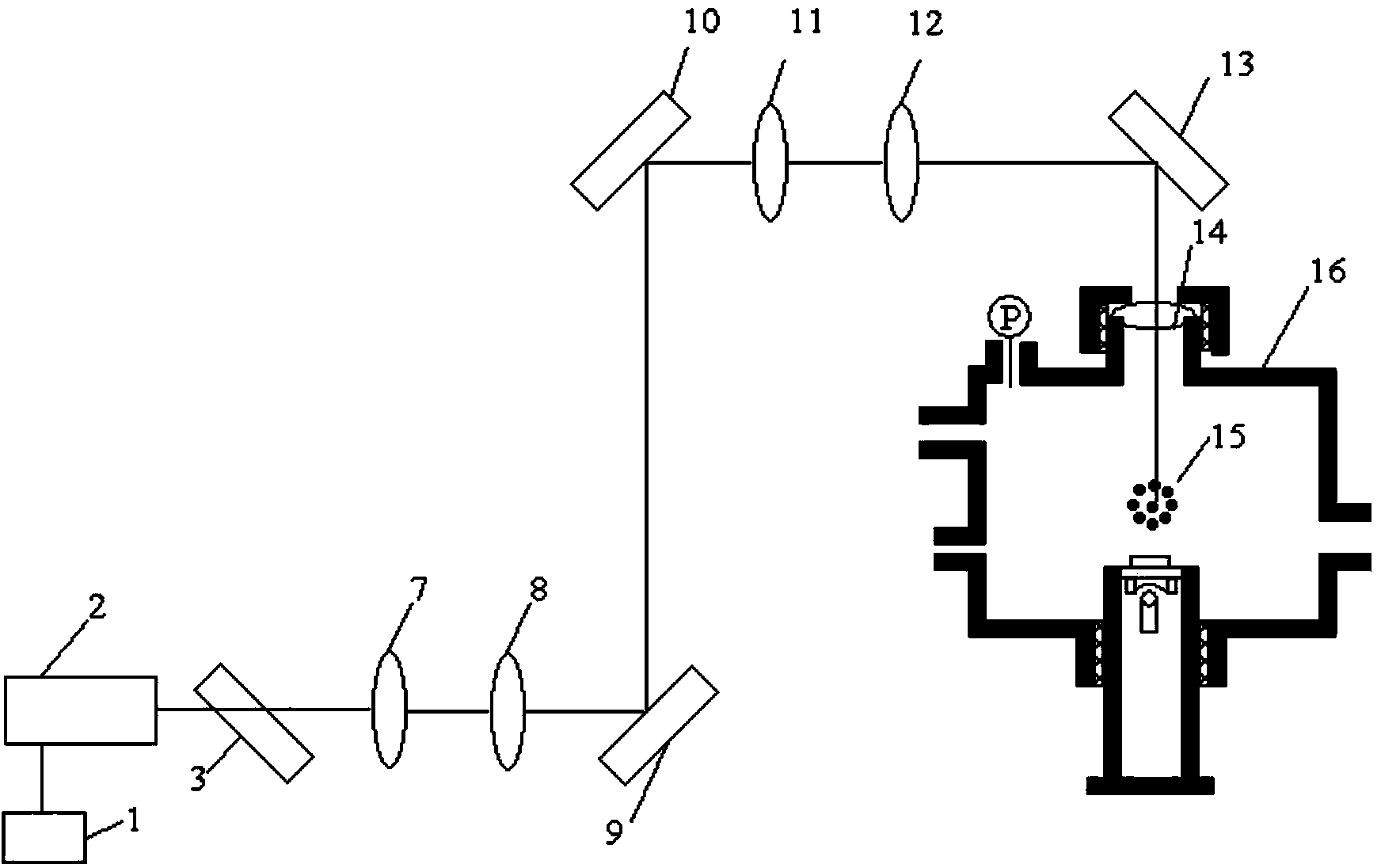

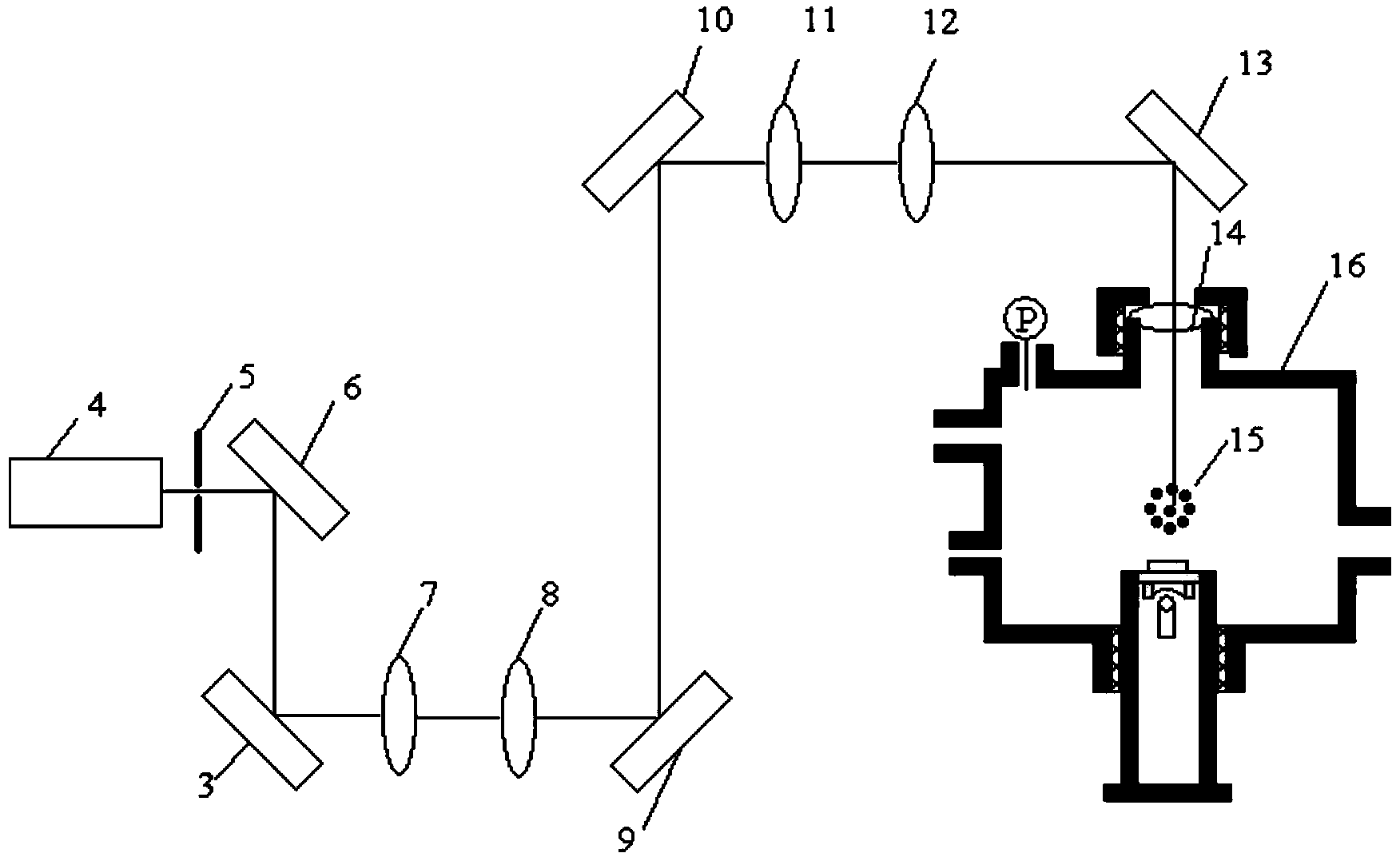

[0022] The present invention will be further described below in conjunction with accompanying drawing.

[0023] Classical holographic technology uses the interference principle of light to record the light wave front emitted by the object in the form of interference fringes to achieve the purpose of freezing the phase information of the light wave of the object; using the diffraction principle of light to reproduce the wave front of the recorded object light wave, we can get The amplitude (intensity) and phase (including position, shape and color) information of an object has unique advantages in the field of optical detection and three-dimensional imaging.

[0024] Digital holography refers to the use of CCD imaging devices instead of ordinary photographic coherent plates to record holograms and reproduce them with digital computing methods; later, the scope of digital holography was expanded to computer-made holograms, photoelectron reproduction holograms, etc., forming a bro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com