Electrodialysis ion-exchange membrane cleaning agent and preparation method thereof

A technology of ion-exchange membrane and cleaning agent, which is applied in the field of cleaning agent for ion-exchange membrane cleaning. It can solve the problems of ion-exchange membrane life-span impact, high cleaning intensity, and long cleaning time, so as to shorten cleaning time and reduce cleaning frequency. , High cleaning efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

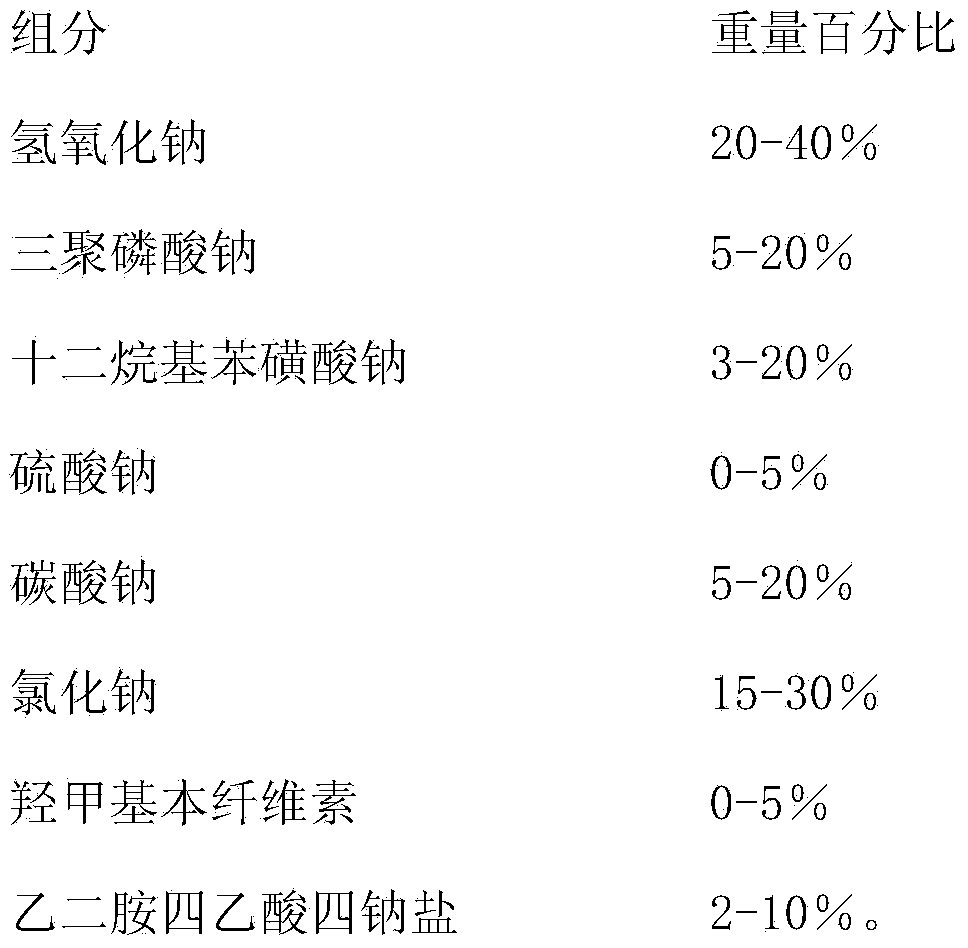

[0024] A preferred formulation of the cleaning agent of the present invention for ion exchange membrane serious pollution cleaning when being preferentially used for electrodialysis desalination treatment of refinery cycle cooling sewage is as follows (weight percent):

[0025]

[0026] In a corrosion-resistant reactor with stirring and grinding, sequentially add sodium hydroxide, sodium tripolyphosphate, sodium dodecylbenzenesulfonate, sodium sulfate, sodium carbonate, hydroxymethyl base Cellulose and ethylenediaminetetraacetic acid tetrasodium salt are stirred at room temperature for 4-6 hours and ground evenly, which is the granular cleaning agent of the present invention.

Embodiment 2

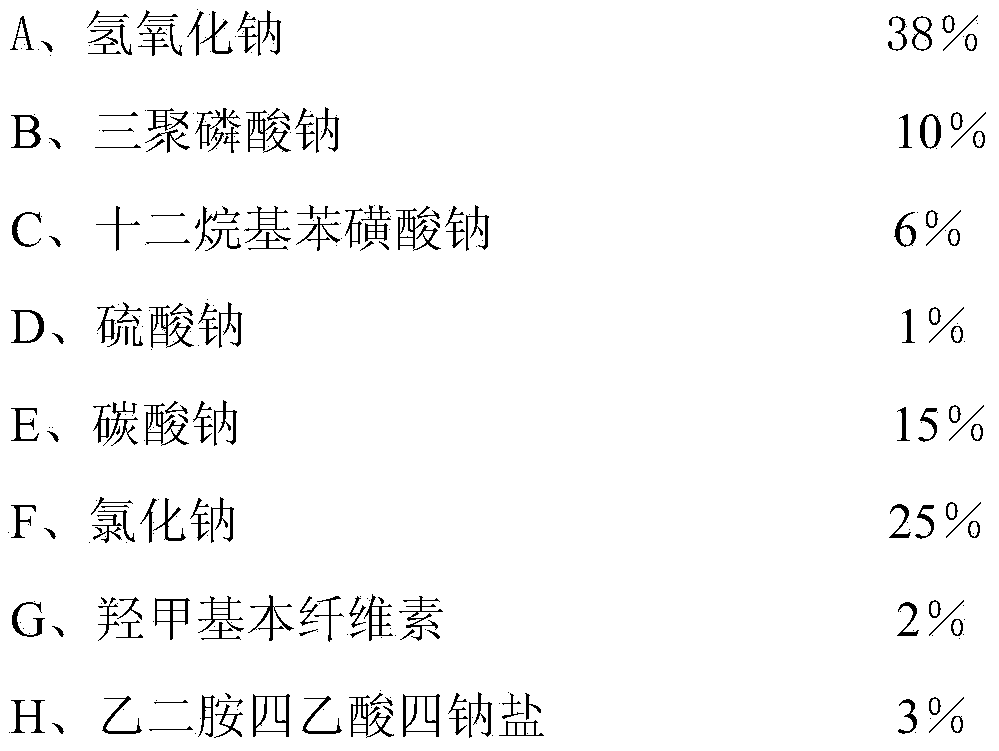

[0028] Another preferred formulation of the cleaning agent of the present invention that is preferentially used for electrodialysis desalination treatment of refinery cycle cooling sewage, ion exchange membrane serious pollution cleaning is as follows (weight percentage):

[0029]

[0030]

[0031] In a corrosion-resistant reactor with stirring and grinding, add sodium hydroxide, sodium tripolyphosphate, sodium dodecylbenzenesulfonate, sodium sulfate, sodium carbonate, and sodium chloride in sequence according to the above components and proportions , hydroxymethyl cellulose, and tetrasodium edetate, stirred at room temperature for 4-6 hours, and ground evenly, is the granular cleaning agent of the present invention.

Embodiment 3

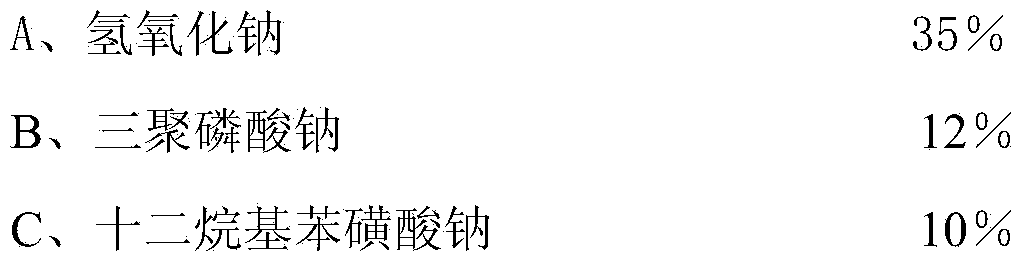

[0033] Another preferred formulation of the cleaning agent of the present invention that is preferentially used for electrodialysis desalination treatment of refining and chemical enterprise circulating cooling effluent, ion-exchange membranes are generally polluted and cleaned as follows (percentage by weight):

[0034]

[0035] In a corrosion-resistant reactor with stirring and grinding, add sodium hydroxide, sodium tripolyphosphate, sodium dodecylbenzenesulfonate, sodium sulfate, sodium carbonate, and sodium chloride in sequence according to the above components and proportions , hydroxymethyl cellulose, and tetrasodium edetate, stirred at room temperature for 4-6 hours, and ground evenly, is the granular cleaning agent of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com