Thermal-insulation mortar

A technology of thermal insulation mortar and absorbent, which is applied in the field of building materials, can solve the problems of low strength, no electromagnetic wave absorption effect, reduce the strength of thermal insulation mortar, etc., and achieve the effect of wide absorption range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

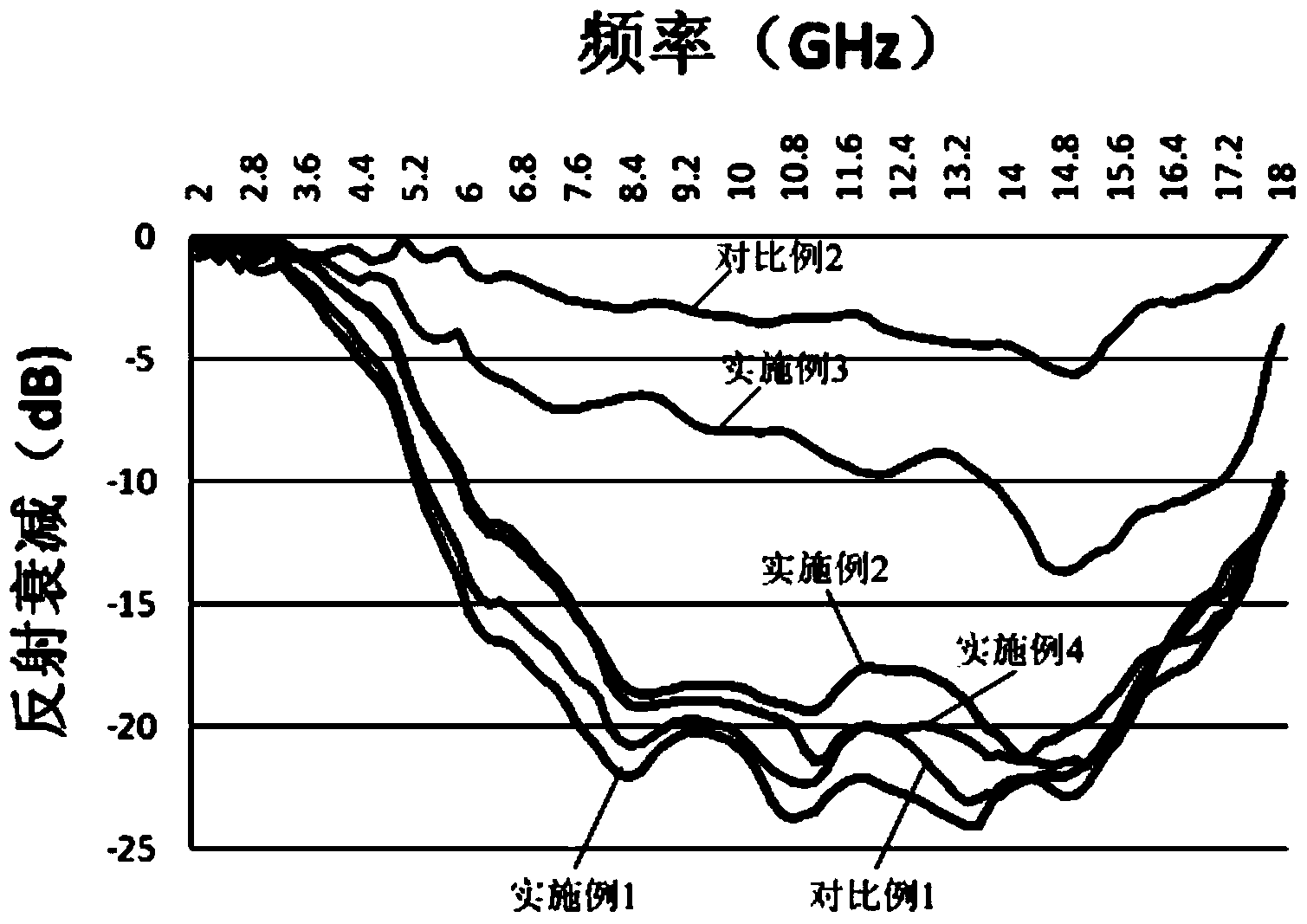

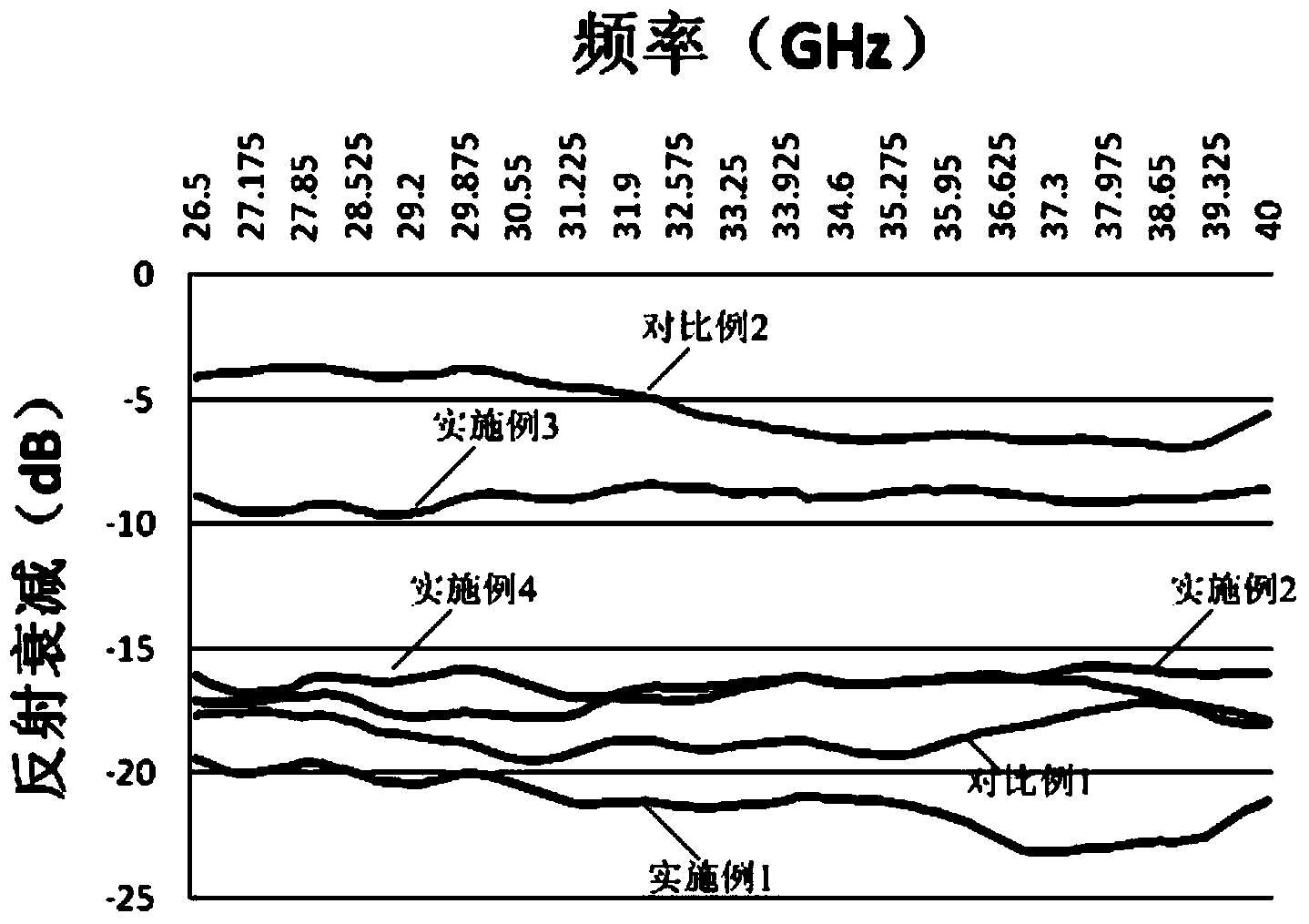

[0031] Add nickel zinc ferrite, 425 ordinary silicon cement, gray calcium, vitrified microspheres, polypropylene fiber, redispersible latex powder, hydroxypropyl methylcellulose and starch ether into the mortar mixer, mix well, Obtain the thermal insulation mortar of this embodiment. Among them, the quality of each component is as follows: nickel zinc ferrite 0.182kg, 425 ordinary silicon cement 2.6kg, ash calcium 1.1kg, vitrified microspheres 6kg, polypropylene fiber 0.03kg, redispersible latex powder 0.1kg, hydroxyl Propyl methyl cellulose 0.02kg and starch ether 0.002kg. The dry density of the insulation mortar is 377g / cm 3 , The thermal conductivity is 0.078W / (m·K). Add water to the thermal insulation mortar of this embodiment and stir it into a slurry, make a 4cm thick sample, and measure the wave-absorbing properties of its 2-18GHz frequency band and 26.5-40GHz frequency band, respectively as figure 1 and figure 2 shown.

Embodiment 2

[0033]Add magnesium zinc ferrite, 425 ordinary silicon cement, fly ash, vitrified microspheres, expanded perlite, polypropylene fiber, redispersible latex powder, hydroxypropyl methylcellulose and starch ether to the mortar mixer In, mix evenly, obtain the insulation mortar of this embodiment. Among them, the quality of each component is as follows: magnesium zinc ferrite 0.746kg, 425 ordinary silicon cement 3.84kg, fly ash 1.54kg, vitrified microspheres 7.1kg, expanded perlite 1.57kg, polypropylene fiber 0.031kg, recyclable Dispersible latex powder 0.12kg, hydroxypropyl methylcellulose 0.03kg and starch ether 0.003kg. The dry density of the insulation mortar is 383g / cm 3 , The thermal conductivity is 0.081W / (m·K). Add water to the thermal insulation mortar of this embodiment and stir it into a slurry, make a 4cm thick sample, and measure the wave-absorbing properties of its 2-18GHz frequency band and 26.5-40GHz frequency band, respectively as figure 1 and figure 2 shown....

Embodiment 3

[0035] Add nickel zinc ferrite, 425 ordinary silicon cement, gray calcium, fly ash, vitrified microspheres, expanded perlite, polypropylene fiber, redispersible latex powder, hydroxypropyl methylcellulose and starch ether In the mortar mixer, mix evenly, obtain the insulation mortar of this embodiment. Among them, the quality of each component is as follows: nickel-zinc ferrite 0.2kg, 425 ordinary silicon cement 9.9kg, ash calcium 0.3kg, fly ash 1.84kg, vitrified microspheres 3.81kg, expanded perlite 3.22kg, polypropylene fiber 0.196kg, 0.4kg of redispersible latex powder, 0.1kg of hydroxypropyl methylcellulose and 0.01kg of starch ether. The dry density of the insulation mortar is 394g / cm 3 , The thermal conductivity is 0.083W / (m·K). Add water to the thermal insulation mortar of this embodiment and stir it into a slurry, make a 4cm thick sample, and measure the wave-absorbing properties of its 2-18GHz frequency band and 26.5-40GHz frequency band, respectively as figure 1 a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com