A kind of hydrogel contact lens and preparation method thereof

A contact lens and hydrogel technology, applied in glasses/goggles, instruments, optics, etc., can solve the problems of poor hydrophilicity, weakened interaction, discomfort, etc., and achieve the effect of high water content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

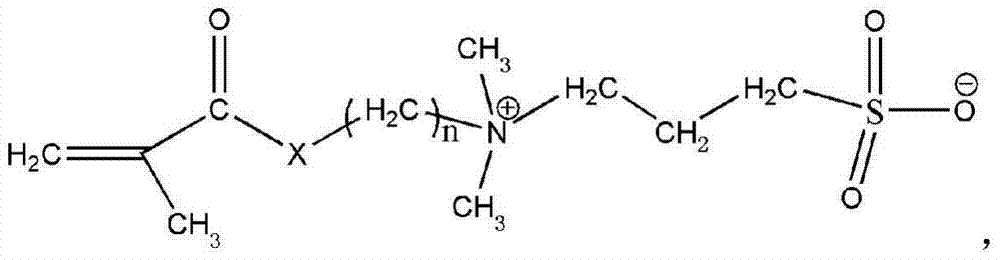

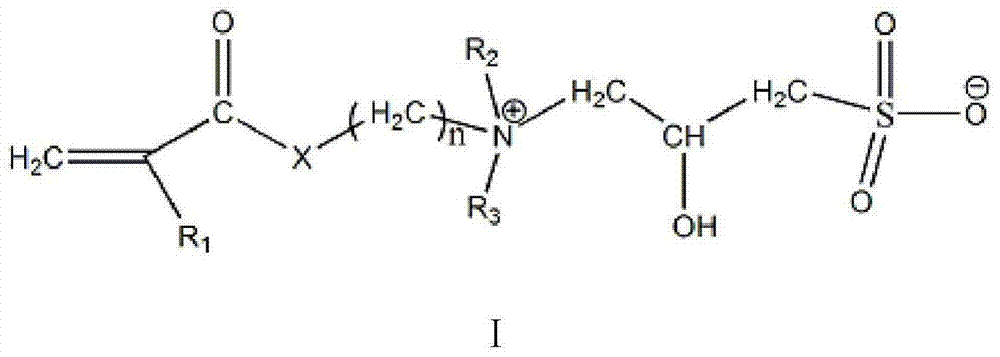

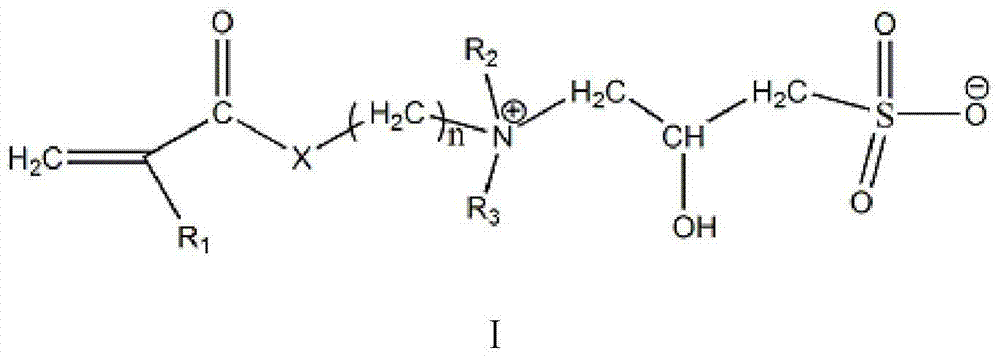

[0041] The invention discloses a method for preparing a hydrogel contact lens, which is characterized in that the polymerizable composition of sulfobetaine zwitterionic monomer, polymerizable monomer, crosslinking agent, and free radical initiator is initiated by ultraviolet light in a mold Or heat-induced polymerization, and further hydration. The contact lens has the characteristics of high water content, high hydrophilicity, anti-dehydration and anti-protein and lipid deposition. The polymerizable composition may further comprise agents of the group consisting of toners, UV absorbers, colorants, antimicrobial agents.

[0042] A kind of hydrogel contact lens of the present invention and preparation method thereof, the measurement of relevant parameter is according to following method:

[0043] 1. Moisture content

[0044] Soak the contact lens in the preset solution until the swelling balance is reached, then take out the moisture on the surface with filter paper and weigh...

example 1

[0059] Example 1 (comparative example)

[0060] 2.55 grams of β-hydroxyethyl methacrylate, 0.015 grams of ethylene glycol dimethacrylate, 0.015 grams of initiator alkyl aryl ketone Darocur-1173, mix well, inject into the mold, cure with UV light, and release the mold , soaked and washed, and placed in physiological saline to obtain a hydrogel contact lens. The material is optically transparent, with a water content of 38%, a Young's modulus of 1.4MPa, a water contact angle of 78 degrees, and a protein adsorption capacity of 80μg / cm 2 ,RPD 10 35%.

example 2

[0062] 2.40 g of β-hydroxyethyl methacrylate, 0.15 g of dimethylaminoethyl methacrylate-2-hydroxy-propyl sulfonate, 0.01 g of ethylene glycol dimethacrylate, 0.015 g of initiator alkane Aryl ketone Darocur-1173, mixed evenly, poured into a mold, cured by ultraviolet light, demolded, soaked and washed, placed in physiological saline to obtain a hydrogel contact lens. The material is optically transparent, with a water content of 47%, a Young's modulus of 1.2 MPa, a water contact angle of 55 degrees, and a protein adsorption capacity of 36 μg / cm 2 , RPD 10 18%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| water contact angle | aaaaa | aaaaa |

| water contact angle | aaaaa | aaaaa |

| water contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com