Method for preparing nanometer surface coating

A surface coating and nanotechnology, applied in the coating, metal material coating process, etc., can solve the problems of inability to ensure high density and high adhesion of the coating, depositing a dense coating, and difficulty in direct spraying, etc. Achieve the effect of low cost, increased diffusion depth and high adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The method for preparing nanometer surface coating of the present embodiment, comprises the following steps:

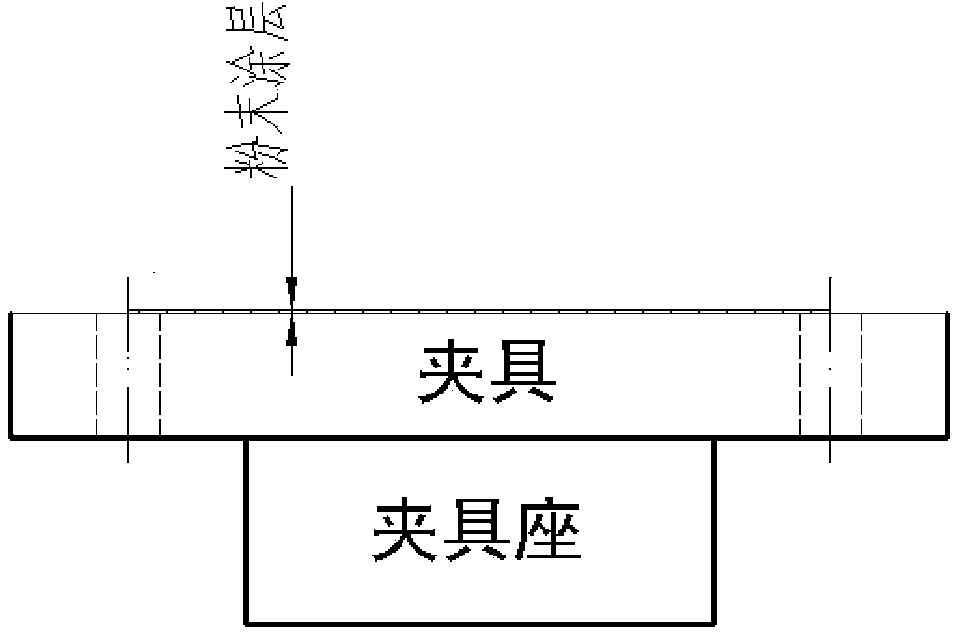

[0025] 1) After ball milling the self-propagating reaction nickel-aluminum mixed powder for 6 hours, coat it on the surface of the metal plate (carbon steel plate) with a coating thickness of 2mm, such as figure 1 shown;

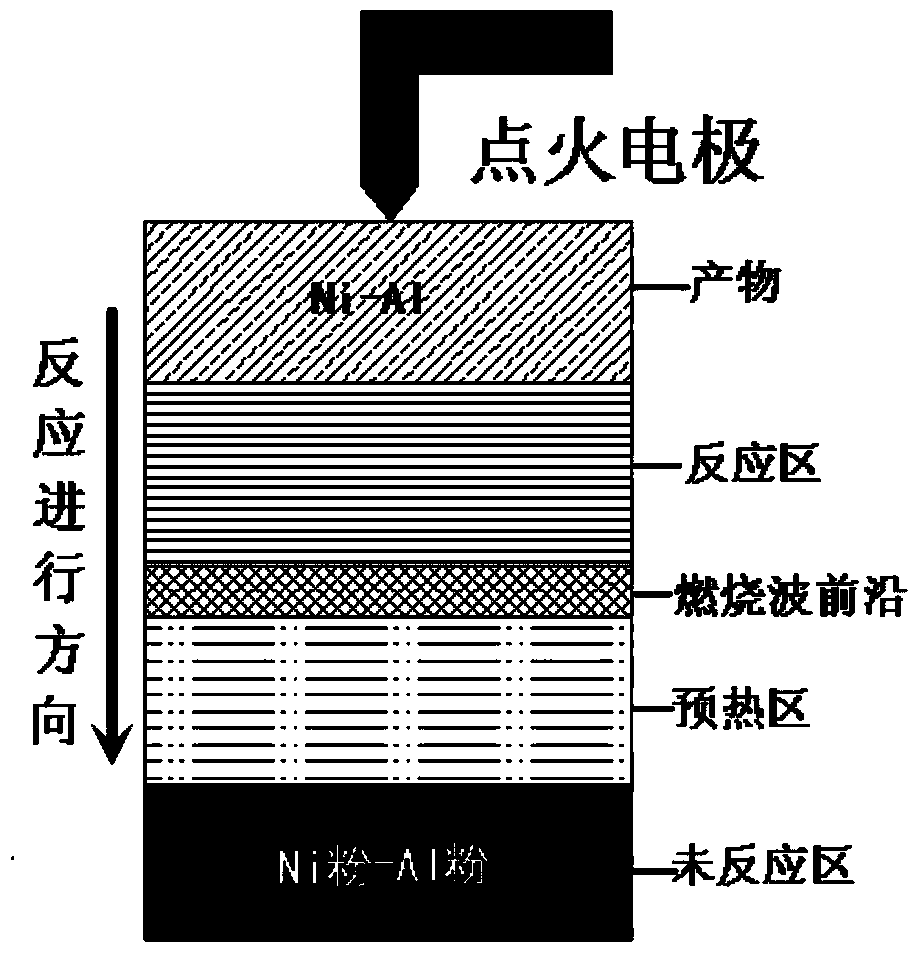

[0026] 2) Use a resistance wire to ignite the nickel-aluminum mixed powder coating coated on the surface of the metal plate, and the nickel-aluminum mixed powder coating undergoes a self-propagating reaction, figure 2 Shown is the self-propagating reaction mechanism of the powder coating in the depth direction, while the depth reaction, the self-propagating reaction will expand in the plane direction;

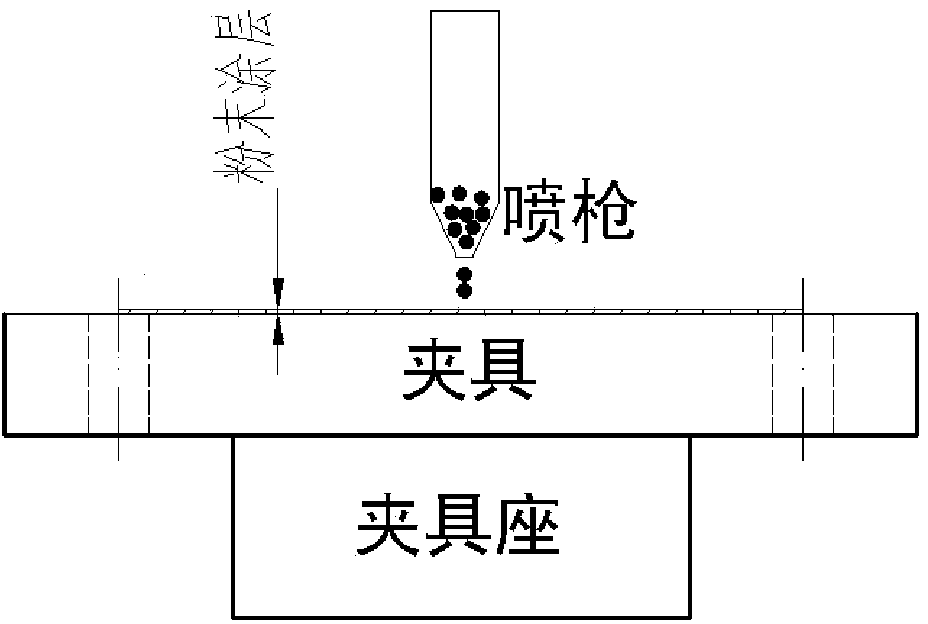

[0027] 3) The nickel-aluminum mixed powder coating is subjected to shot peening within 30s after the self-propagating reaction occurs, such as image 3 As shown, the shot peening angle is 90 degrees, the shot peening speed is 100m / s, the sh...

Embodiment 2

[0029] The method for preparing nanometer surface coating of the present embodiment, comprises the following steps:

[0030] 1) After ball milling the self-propagating reaction nickel-titanium mixed powder for 4 hours, it is coated on the surface of the metal plate (carbon steel plate) with a coating thickness of 2mm, such as figure 1 shown;

[0031] 2) Use a resistance wire to ignite the nickel-titanium mixed powder coating coated on the surface of the metal plate, and the nickel-titanium mixed powder coating will undergo a self-propagating reaction;

[0032] 3) The nickel-titanium mixed powder coating is subjected to shot peening within 15s after the self-propagating reaction occurs, such as image 3 As shown, the shot peening angle is 90 degrees, the shot peening speed is 100m / s, the shot peening type is carbon steel ball, and the shot peening size is 20μm; after the self-propagating reaction and shot peening treatment, the nanometer surface coating is obtained .

Embodiment 3

[0034] The method for preparing nanometer surface coating of the present embodiment, comprises the following steps:

[0035] 1) After ball milling the self-propagating reaction titanium-carbon mixed powder for 2 hours, coat it on the surface of the metal plate (carbon steel plate) with a coating thickness of 2 mm, such as figure 1 shown;

[0036] 2) Ignite the titanium-carbon mixed powder coating coated on the surface of the metal plate with a resistance wire, and the titanium-carbon mixed powder coating undergoes a self-propagating reaction;

[0037] 3) The titanium-carbon mixed powder coating is subjected to shot peening within 25s after the self-propagating reaction occurs, such as image 3 As shown, the shot peening angle is 90 degrees, the shot peening speed is 100m / s, the shot peening type is carbon steel ball, and the shot peening size is 20μm; after the self-propagating reaction and shot peening treatment, the nanometer surface coating is obtained .

[0038] In the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com