Method for manufacturing rutile-type titanium dioxide monocrystal nanowire arrays at normal pressure and low temperature

A nanowire array and titanium dioxide technology is applied in the field of low-temperature preparation of rutile-type titanium dioxide single crystal nanowire arrays, which can solve the problems of easy explosion, danger to people and equipment, and achieve the effects of low cost, easy operation and control, and simple process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] (1) Measure 0.5mL of titanium trichloride (commercially available, the same below) and 40mL of nonanoic acid, mix them in a polytetrafluoroethylene container reaction device, stir with a magnetic stirrer for 20 minutes at room temperature, and set aside;

[0033] (2) Tighten the polytetrafluoroethylene container and put it into the incubator, set the reaction temperature to 150°C, and the reaction time to 12 hours, and naturally cool to room temperature after the reaction;

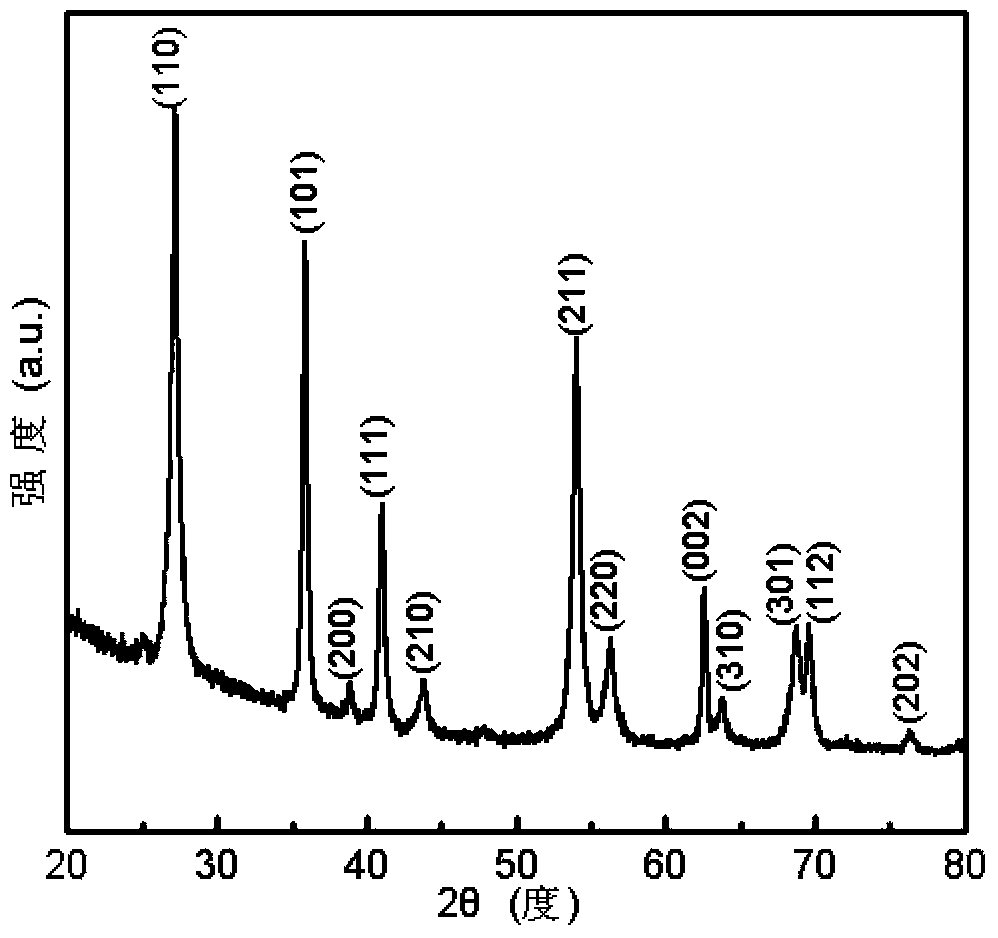

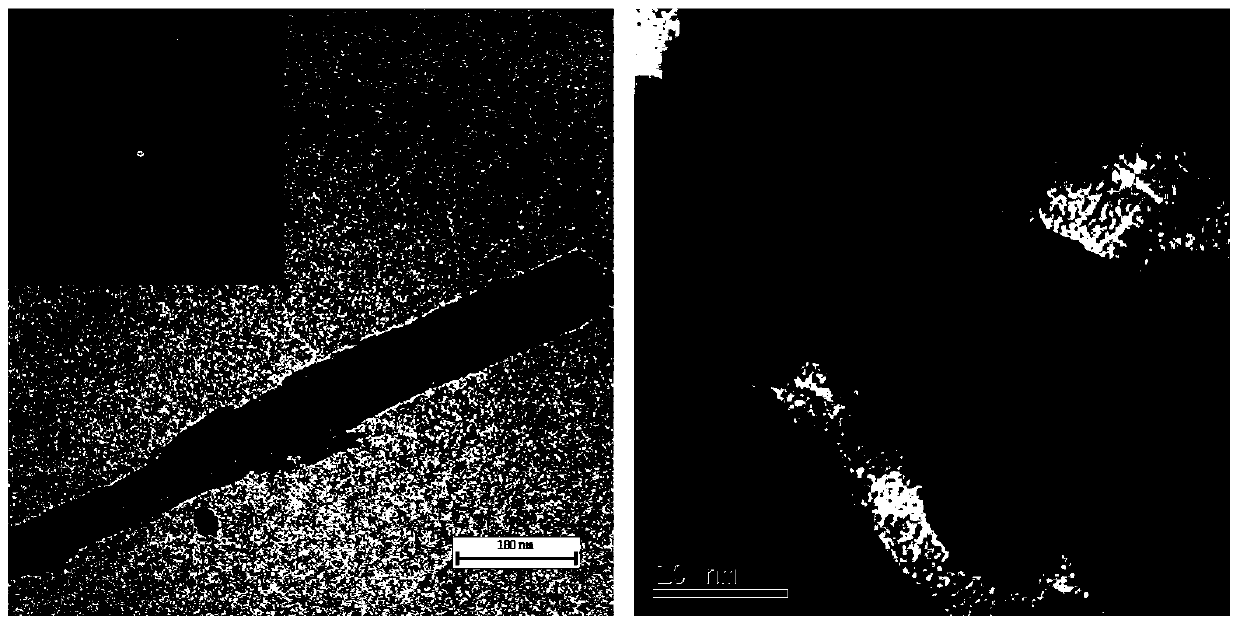

[0034] (3) After opening the polytetrafluoroethylene container of step polymer (2), take out the film, wash it several times with deionized water and absolute ethanol, and dry it in a constant temperature box at 60°C for 24 hours. The prepared titanium dioxide single The XRD pattern of the crystalline nanowire array is as follows figure 1 as shown in the figure 1 It can be seen that the marked crystal plane diffraction peaks correspond to titanium dioxide in the rutile crystal phase. figure 2 (a)...

Embodiment 2

[0036] (1) Measure 0.5mL of titanium trichloride and 40mL of nonanoic acid and mix them in a glass bottle container reaction device. The glass container is borosilicate glass, and stir with a magnetic stirrer for 20 minutes at room temperature for later use;

[0037] (2) Tighten the glass bottle and place it in an incubator, set the reaction temperature to 90°C, and the reaction time to 12 hours, and naturally cool to room temperature after the reaction;

[0038] (3) After opening the glass bottle of step polymer (2), take out the film and wash it several times with absolute ethanol and alcohol, and dry it in a constant temperature box at 60°C for 24 hours. The prepared titanium dioxide single crystal nanowire array XRD patterns such as Figure 4 as shown in the Figure 4 It can be seen that the marked crystal plane diffraction peaks correspond to titanium dioxide in the rutile crystal phase. Figure 5 As shown in the scanning electron microscope pictures, the prepared sampl...

Embodiment 3

[0040] (1) Measure 0.5mL of titanium trichloride and 40mL of nonanoic acid and mix them in a glass bottle container reaction device. The glass container is borosilicate glass, and stir with a magnetic stirrer for 20 minutes at room temperature for later use;

[0041] (2) Tighten the glass bottle and place it in an incubator, set the reaction temperature to 90°C, and the reaction time to 12 hours, and naturally cool to room temperature after the reaction;

[0042] (3) After opening the glass bottle of step polymer (2), take out the film and wash it several times with absolute ethanol and alcohol, and dry it in an incubator at 50°C for 36 hours. The prepared sample is composed of titanium dioxide nanowires The corresponding film thickness is 3.7 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com