Preparation method for monophosphate-adjuvant water-soluble fluorescent carbon quantum dot solid powder

A technology of carbon quantum dots and solid powders, which is applied in the field of preparation of single phosphate-assisted water-soluble fluorescent carbon quantum dot solid powders, which can solve the difficulty of separation and purification of passivating agents, low effective yield, and difficulty in large-scale production Production application and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

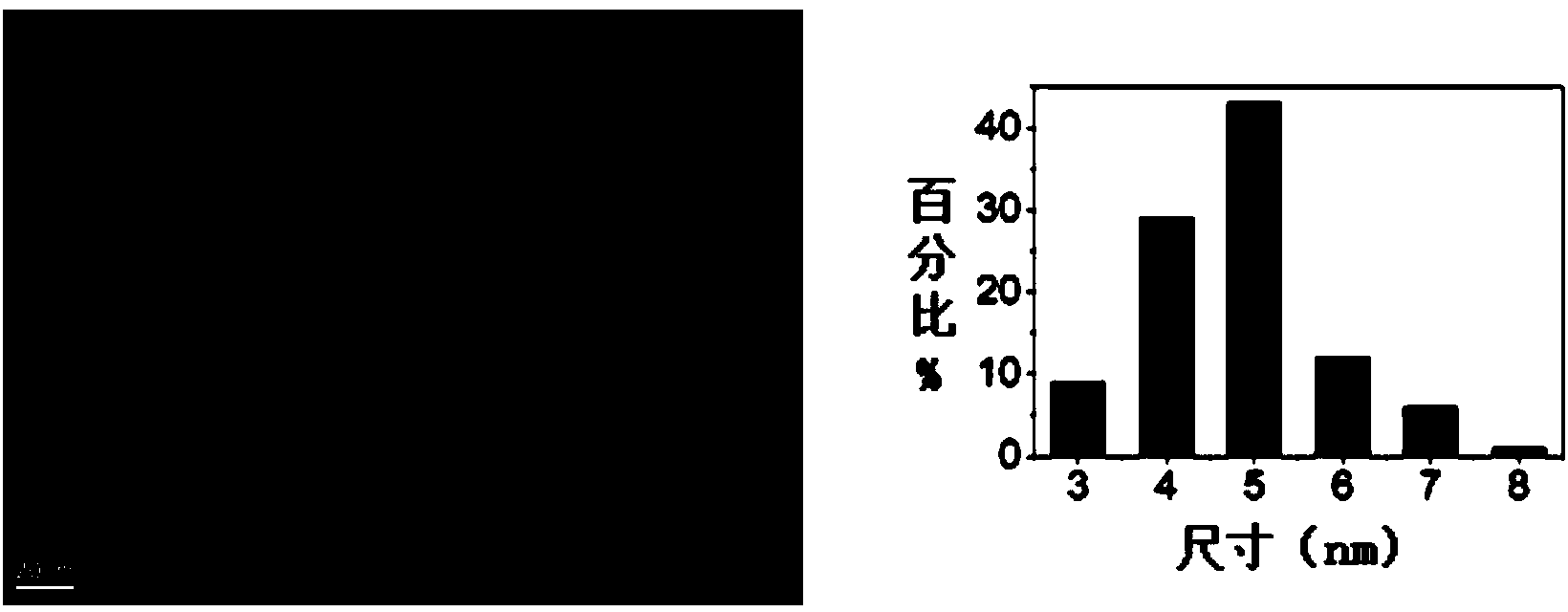

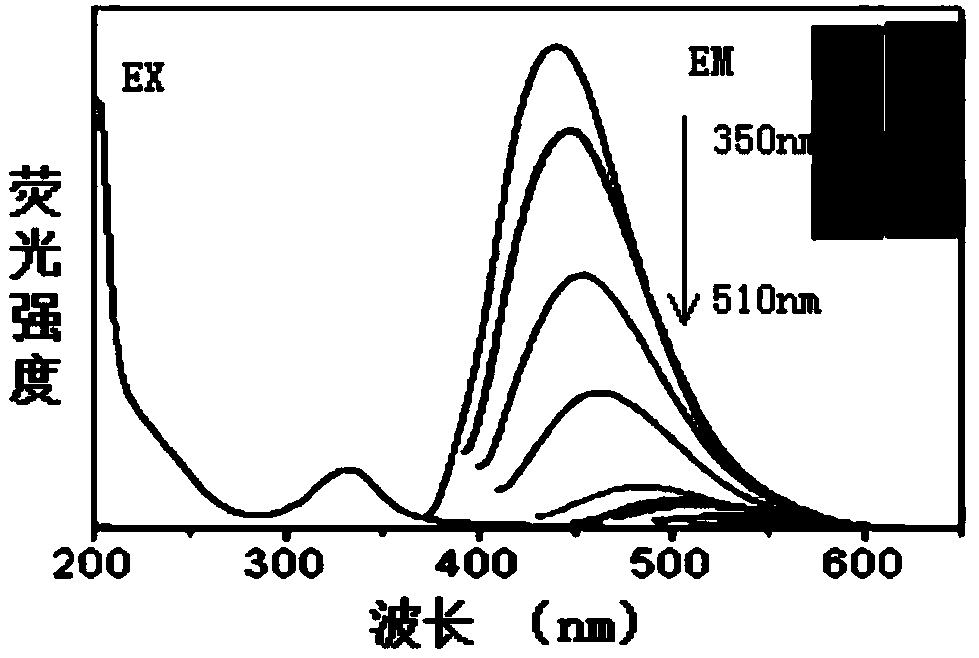

Image

Examples

Embodiment 1

[0029] A rapid preparation method for water-soluble fluorescent carbon quantum dot solid powder assisted by single phosphate, comprising the following steps:

[0030] (1) Take 5.0g of ammonium citrate and add it to 10mL sodium monohydrogen phosphate solution with a concentration of 0.4mol / L. The molar ratio of ammonium citrate and sodium monohydrogen phosphate is 5:1. Ultrasound at room temperature for 2 minutes to mix the solution evenly. A colorless homogeneous transparent solution was obtained.

[0031] (2) Put the transparent solution into a beaker and place it in a microwave oven, heat it in a 750W microwave oven for 2min20s, and obtain a brown-yellow solid powder containing carbon quantum dots in the beaker.

[0032] (3) Dissolve the solid obtained in step (2) in a mixed solution of ethanol and water (volume fraction of ethanol is 75%), ultrasonically disperse for 5 minutes, and centrifuge at 6000r / min for 8 minutes in a high-speed centrifuge to remove the lower precipit...

Embodiment 2

[0037] A rapid preparation method for water-soluble fluorescent carbon quantum dot solid powder assisted by single phosphate, comprising the following steps:

[0038] (1) Take 2.5g of ammonium citrate and add it to 10mL of potassium monohydrogen phosphate solution with a concentration of 0.5mol / L. The molar ratio of potassium monohydrogen phosphate and ammonium citrate is 2:1. Ultrasound at room temperature for 1min to mix the solution evenly. A colorless homogeneous transparent solution was obtained.

[0039] (2) Put the transparent solution into a beaker and place it in a microwave oven, heat it with a 750W microwave for 2min15s, and obtain a dark yellow solid containing carbon quantum dots in the beaker.

[0040] (3) Dissolve the solid obtained in step (2) in a mixed solution of ethanol and water (volume fraction of ethanol is 80%), ultrasonically disperse for 3 minutes, and centrifuge at 4500r / min in a high-speed centrifuge for 7 minutes to remove the lower sediment.

[0...

Embodiment 3

[0044] A rapid preparation method for water-soluble fluorescent carbon quantum dot solid powder assisted by single phosphate, comprising the following steps:

[0045] (1) Add 4.0g glycine to 10mL potassium monohydrogen phosphate solution with a concentration of 1mol / L, the molar ratio of glycine and potassium monohydrogen phosphate is 5:1, and ultrasonically mix the solution for 1.5min at room temperature to obtain a colorless uniform transparent solution.

[0046] (2) Put the transparent solution into a beaker, place it in a microwave oven, and heat it with a 750W microwave for 2 minutes, and a dark yellow solid containing carbon quantum dots is obtained in the beaker.

[0047] (3) Dissolve the solid obtained in step (2) in a mixed solution of ethanol and water (volume fraction of ethanol is 90%), ultrasonically disperse for 4 minutes, and centrifuge with a high-speed centrifuge at 8000r / min for 6 minutes to remove the lower sediment.

[0048] (4) Add 5g of D201 macroporous ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com