A method for preparing nitrogen-doped carbon quantum dots by solid-state pyrolysis and its application

A technology of carbon quantum dots and nitrogen doping, which is applied in the field of preparing nitrogen-doped carbon quantum dots by solid-state pyrolysis, can solve the problems of complex instruments and equipment, post-processing, restrictions, etc., and achieve small particle size, uniform distribution, good selective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

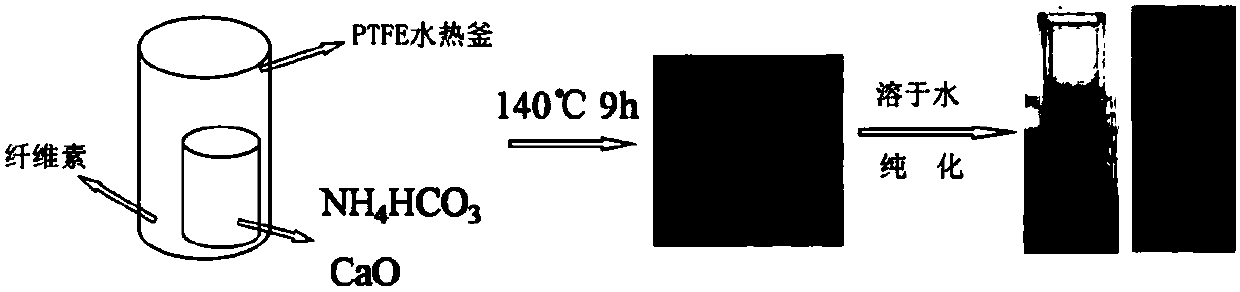

[0045] The present invention utilizes solid-phase pyrolysis method to prepare nitrogen-doped carbon quantum dots, the detailed steps of the preparation method are as follows:

[0046] a. First take 0.5g of microcrystalline cellulose and lay it flat in a polytetrafluoroethylene hydrothermal kettle, then place a glass vial with 2g ammonium bicarbonate and 3g calcium oxide in a hydrothermal kettle. In the process, Ammonium bicarbonate decomposes to produce ammonia, and the ammonia decomposed by ammonium bicarbonate in the hydrothermal kettle is excessive;

[0047] b. In a non-closed system, place the polytetrafluoroethylene hydrothermal kettle in an electric thermostat for heating, and heat up to 70°C; use the ammonia gas generated by the thermal decomposition of ammonium bicarbonate to drive out the air in the hydrothermal kettle;

[0048] c. Seal the hydrothermal kettle after removing the air in step b, set the reaction temperature to 140°C and the reaction time to 9h, and perf...

Embodiment 2

[0051] Embodiment 2: basically the same as Embodiment 1, the difference is:

[0052] In step c: set the reaction temperature to 120° C., and the reaction time to 9 h.

Embodiment 3

[0053] Embodiment 3: basically the same as Embodiment 1, the difference is:

[0054] In step c: set the reaction temperature to 160° C., and the reaction time to 9 h.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com