Method for rapidly preparing thick-wall CdTe/CdS quantum dot with controllable shell thickness

A technology of quantum dots and quantum dot solutions, which is applied in the field of nanomaterial preparation, can solve problems such as high reaction temperature, harsh reaction conditions, and long reaction time, and achieve the effects of strong controllability, uniform particle size, and good dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] (a) Preparation of CdTe nuclear quantum dot solution

[0033] Add 115 mg CdCl to a 1 L two-necked bottle 2 , dissolved in 500 mL of ultrapure water, then added 199 μL of MPA solution, stirred evenly, added NaOH solution to adjust the pH value of the solution to 9, injected high-purity nitrogen gas into the cadmium source solution for 30 min, and added the newly prepared NaHTe solution 0.25 mL, heated to reflux for 40 min. After the reaction solution was cooled to room temperature, concentrated by rotary evaporation, an appropriate amount of isopropanol was added, and purified by high-speed centrifugation.

[0034] (b) Preparation of reaction precursor solution

[0035] Add 229 mg CdCl to a 10 mL vial 2 , dissolved in 4 mL of ultrapure water, and then added 109 μL of MPA solution and 891 μL of NaOH solution (mass concentration: 20%).

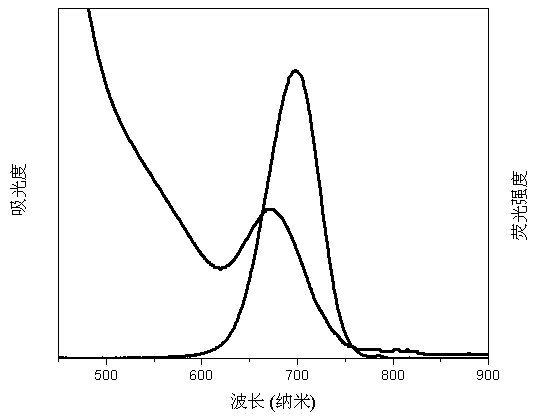

[0036] (c) Growth of CdTe / CdS core-shell quantum dots

[0037] The purified CdTe quantum dot solution was tested by ultraviolet sp...

Embodiment 2

[0039] (a) Preparation of CdTe nuclear quantum dot solution

[0040] Add 115 mg CdCl to a 1 L two-necked bottle 2 , dissolved in 500 mL of ultrapure water, then added 199 μL of MPA solution, stirred evenly, added NaOH solution to adjust the pH value of the solution to 9.5, injected high-purity nitrogen into this cadmium source solution for 30 min, and added newly prepared NaHTe solution 0.25 mL, heated to reflux for 60 min. After the reaction solution was cooled to room temperature, concentrated by rotary evaporation, an appropriate amount of isopropanol was added, and purified by high-speed centrifugation.

[0041] (b) Preparation of reaction precursor solution

[0042] Add 229 mg CdCl to a 10 mL vial 2 , dissolved in 3.5 mL of ultrapure water, and then added 164 μL of MPA solution and 1.34 mL of NaOH solution (mass concentration: 20%).

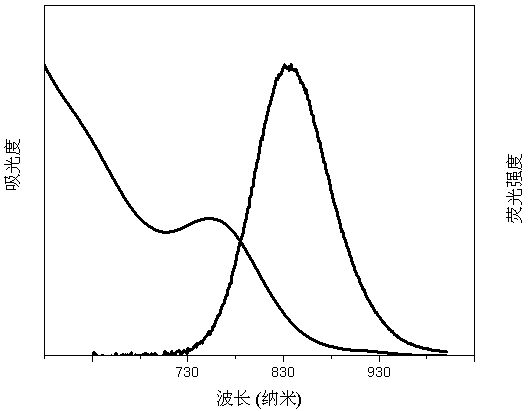

[0043] (c) Growth of CdTe / CdS core-shell quantum dots

[0044] The purified CdTe quantum dot solution was tested by ultraviolet spec...

Embodiment 3

[0046] (a) Preparation of CdTe nuclear quantum dot solution

[0047] Add 115 mg CdCl to a 1 L two-necked bottle 2 , dissolved in 500 mL of ultrapure water, then added 109 μL of MPA solution, stirred evenly, added NaOH solution to adjust the pH of the solution to 8.5, injected high-purity nitrogen into this cadmium source solution for 30 min, and added newly prepared NaHTe solution 0.5 mL, heated to reflux for 45 min. After the reaction solution was cooled to room temperature, concentrated by rotary evaporation, an appropriate amount of isopropanol was added, and purified by high-speed centrifugation.

[0048] (b) Preparation of reaction precursor solution

[0049] Add 229 mg CdCl to a 10 mL vial 2 , dissolved in 3.5 mL of ultrapure water, and then added 164 μL of MPA solution and 1.34 mL of NaOH solution (mass concentration: 20%).

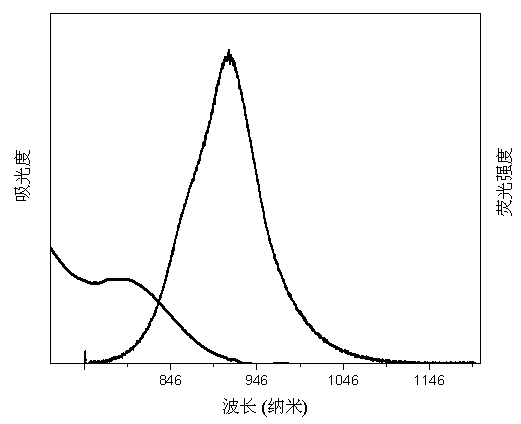

[0050] (c) Growth of CdTe / CdS core-shell quantum dots

[0051] The purified CdTe quantum dot solution was tested by ultraviolet spectrum, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com