A kind of alcohol fermentation accelerator and its preparation method and usage

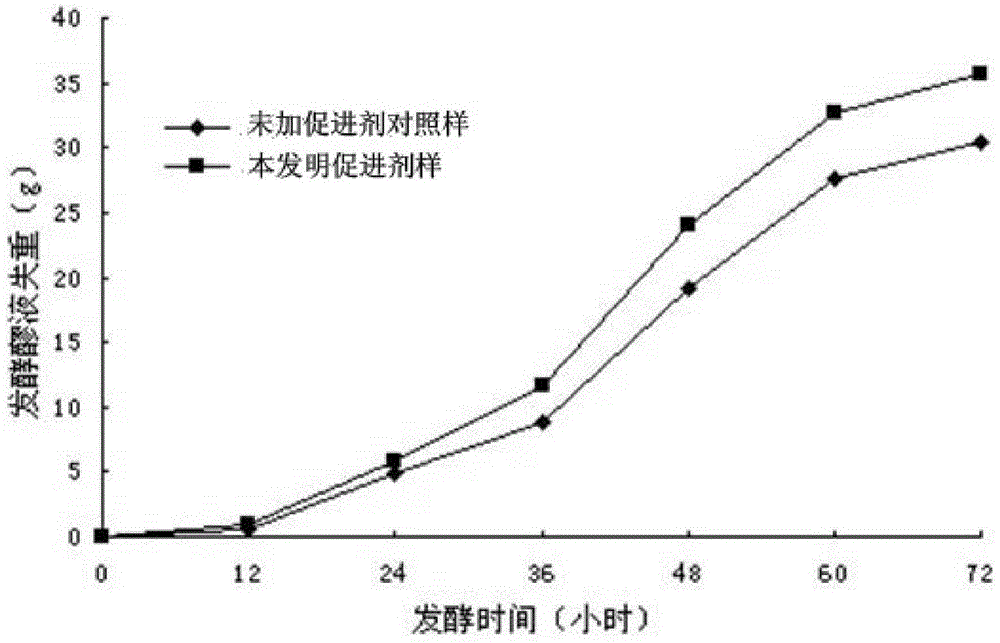

A technology of alcohol fermentation and accelerator, applied in the direction of fermentation, biofuel, etc., can solve the problems of incomplete alcohol fermentation, long fermentation cycle, lack of nutrients, etc., to achieve the ability to promote material exchange, shorten the fermentation cycle, and promote metabolic reproduction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

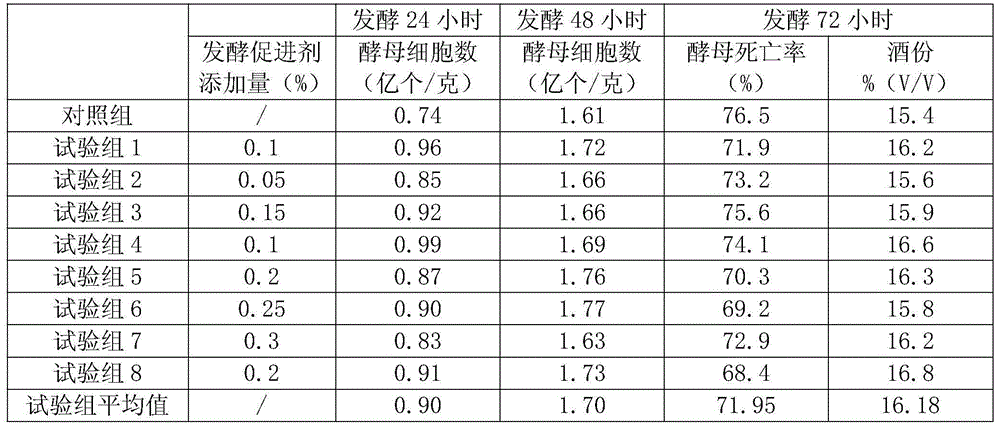

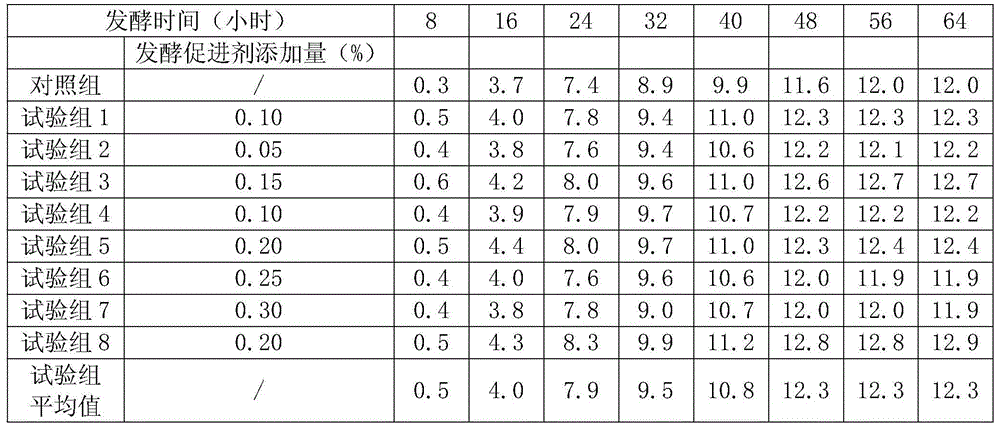

Examples

Embodiment 1

[0050] (1) Preparation of soybean protein hydrolyzate:

[0051] In the first step, the raw soybeans are crushed, then mixed with water, so that the total solid content of the soybean water mixture reaches 15%;

[0052] The second step is to heat the soybean water mixture to 80-90°C, keep it warm for 10 minutes, destroy the molecular structure of soybean protein under high temperature conditions, and then cool it to 40-55°C;

[0053] In the third step, after cooling to 40-55°C, add 7U / g protease to hydrolyze for 4.5 hours based on the substrate raw material;

[0054] The fourth step is to dry the soybean protein hydrolyzate under the condition of 60-70°C until the moisture content is lower than 15%.

[0055] (2) Selection of surface active substance: polyoxyethylene sorbitan fatty acid ester is selected as the surface active substance.

[0056] (3) Preparation of yeast compound nutrients: in parts by weight, weigh 23 parts of manganese sulfate, 12 parts of zinc acetate, 23 pa...

Embodiment 2

[0059] (1) Preparation of soybean protein hydrolyzate:

[0060] In the first step, the raw soybeans are crushed, and then mixed with water, so that the total solid content of the soybean water mixture reaches 25%;

[0061] The second step is to heat the soybean water mixture to 80-90°C, keep it warm for 20 minutes, destroy the molecular structure of soybean protein under high temperature conditions, and then cool it to 40-55°C;

[0062] In the third step, after cooling to 40-55°C, add 10U / g protease to hydrolyze for 6 hours based on the substrate raw material;

[0063] The fourth step is to dry the soybean protein hydrolyzate under the condition of 60-70°C until the moisture content is lower than 15%.

[0064] (2) Selection of surface active substance: Sorbitan fatty acid ester is selected as the surface active substance.

[0065] (3) Preparation of yeast compound nutrients: in parts by weight, weigh 25 parts of manganese sulfate, 15 parts of zinc acetate, 25 parts of calciu...

Embodiment 3

[0068] (1) Preparation of soybean protein hydrolyzate:

[0069] In the first step, the raw soybeans and soybean meal are crushed, and then mixed with water, so that the total solid content of the soybean water mixture reaches 20%;

[0070] The second step is to heat the soybean water mixture to 80-90°C, keep it warm for 15 minutes, destroy the molecular structure of soybean protein under high temperature conditions, and then cool it to 40-55°C;

[0071] In the third step, after cooling to 40-55°C, 7 U / g of protease was added based on the substrate raw material for hydrolysis for 5 hours;

[0072] The fourth step is to dry the soybean protein hydrolyzate under the condition of 60-70°C until the moisture content is lower than 15%.

[0073] (2) Selection of surface active substance: polyethylene glycol was selected as the surface active substance.

[0074] (3) Preparation of yeast compound nutrients: In parts by weight, weigh 23 parts of manganese sulfate, 5 parts of zinc aceta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com