Activating agent for preparation of embedded film resistor, preparation method of embedded film resistor and embedded film resistor

A thin film resistor, embedded technology, applied in resistors, non-adjustable metal resistors, circuits, etc., can solve the problems of unstable plating solution, increased production cost, steam pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

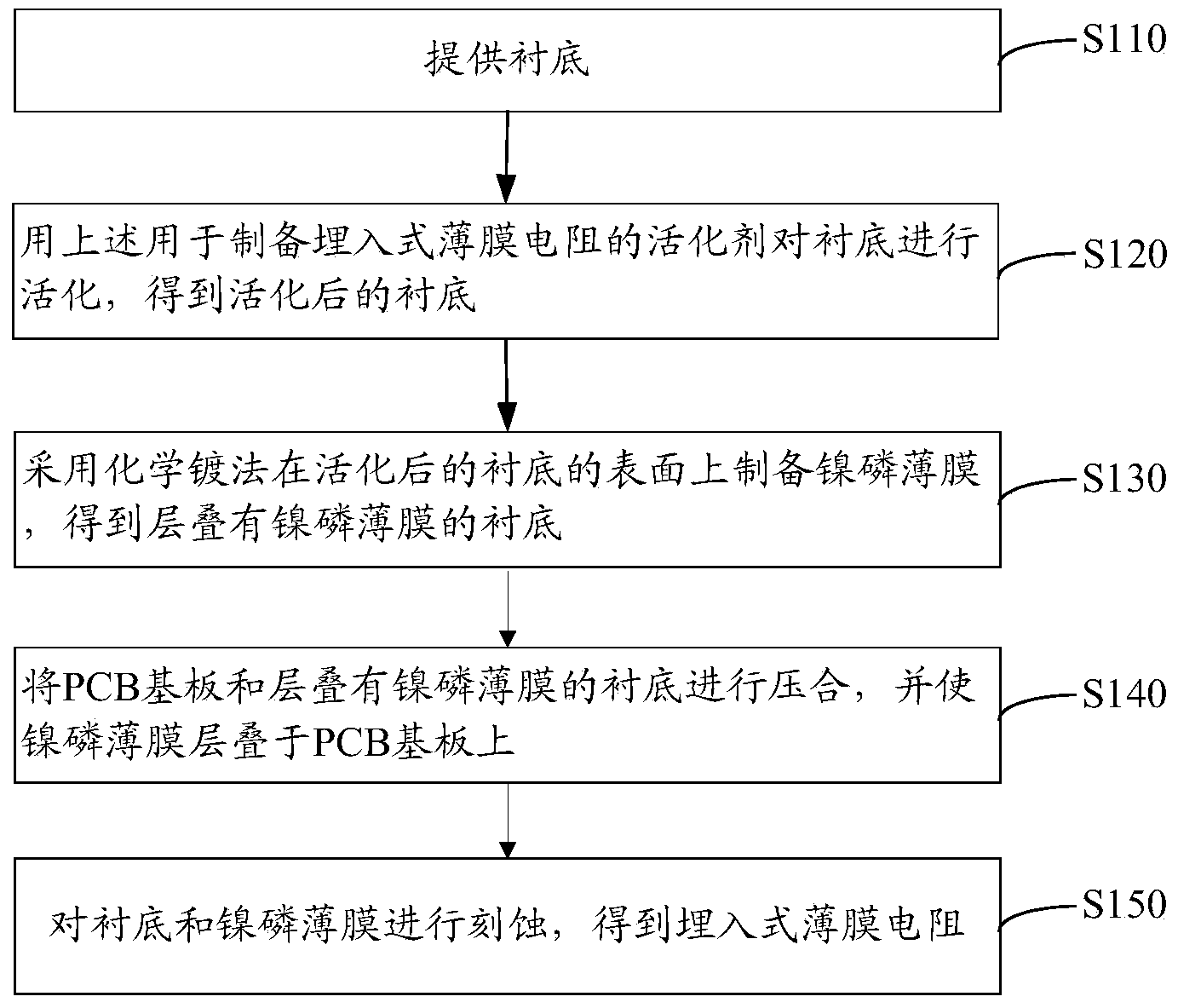

[0041] see figure 1 , the preparation method of the embedded thin film resistor of an embodiment, comprises the following steps:

[0042] Step S110: providing a substrate.

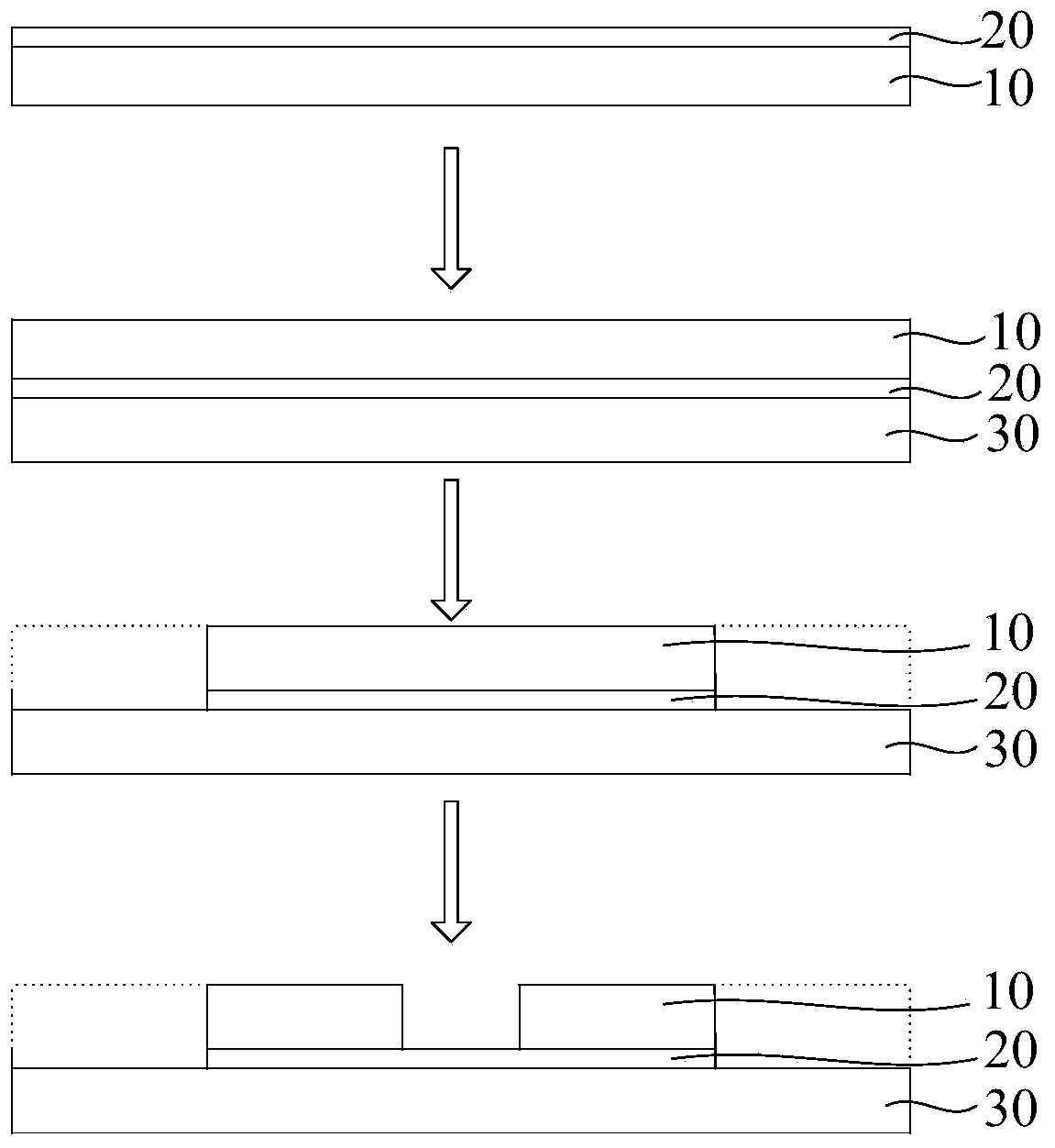

[0043] Please also see figure 2 , the substrate 10 can be copper foil, aluminum foil or aluminum-magnesium alloy, etc., preferably copper foil. Copper foil has relatively smooth and rough sides. If the surface of other substrates is relatively smooth, one of the surfaces of the substrate needs to be roughened to improve the adhesion of the subsequent electroless plating.

[0044] Firstly, the substrate 10 is cut to a required size, and then a photosensitive film (not shown) is pasted on the smooth surface of the substrate 10 and exposed to light to protect the substrate in the subsequent chemical coating step.

[0045] The substrate 10 is further washed. Washing includes washing with a detergent, and then pickling with a sulfuric acid solution with a mass concentration of 5%.

[0046] Dissolving alk...

Embodiment 1

[0084] Fabrication of Embedded Thin Film Resistors

[0085] 1. Provide 8cm×4cm copper foil. The copper foil has a relatively smooth surface and a rough surface. Paste a photosensitive film on the smooth surface of the copper foil and expose it;

[0086] 2. Weigh 10g of washing powder, add 400ml of deionized water, and prepare detergent for degreasing. Put the copper foil in step 1 into the detergent, ultrasonically treat it for 10 minutes, then take it out and wash it with deionized water;

[0087] 3. Take 20ml of concentrated sulfuric acid and prepare it as dilute sulfuric acid with a mass fraction of 5%. Put the copper foil treated in step 2 into the dilute sulfuric acid, pickle it for 10 minutes, and then take it out and wash it with deionized water;

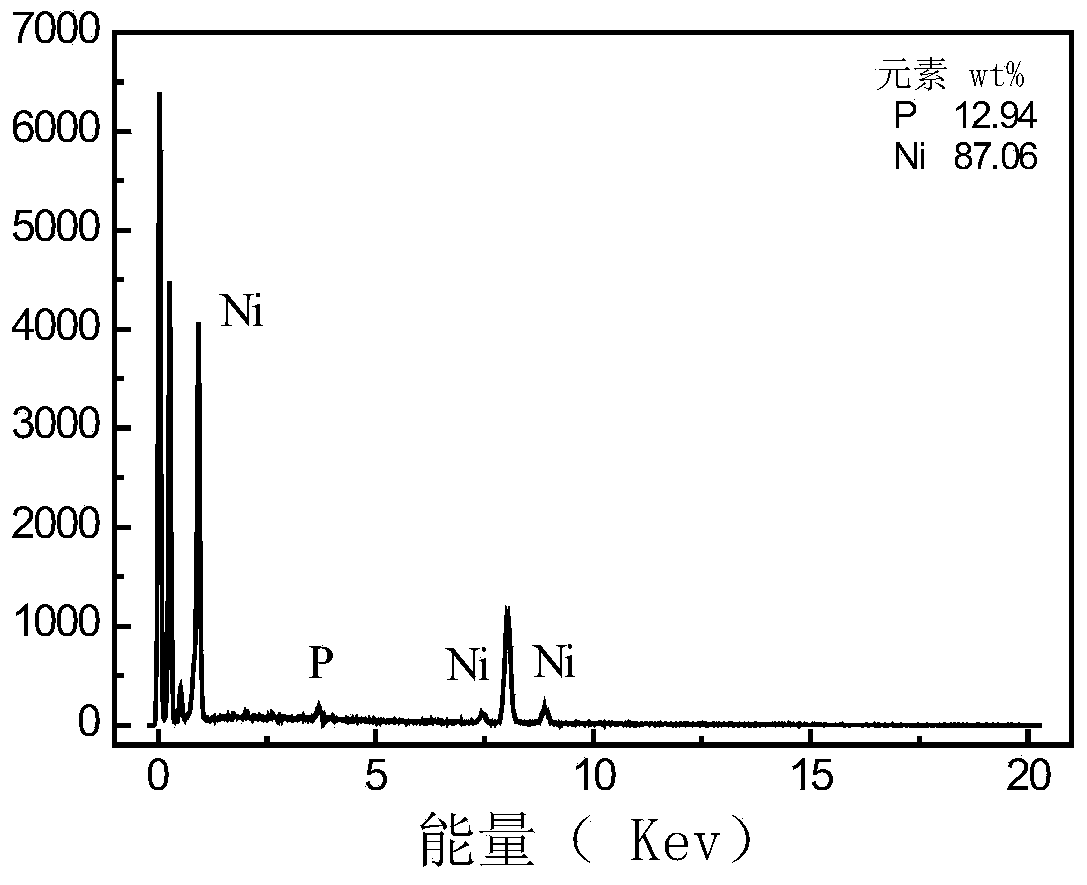

[0088] 4. Weigh 35g of zinc sulfate, 3.5g of DL-sodium malate and 5g of zinc powder into deionized water to prepare 200mL of activator for the preparation of embedded thin film resistors, heat the activator to 40°C, and then...

Embodiment 2

[0102] Fabrication of Embedded Thin Film Resistors

[0103] 1. Provide 8cm×4cm copper foil. The copper foil has a relatively smooth surface and a rough surface. Paste a photosensitive film on the smooth surface of the copper foil and expose it;

[0104] 2. Weigh 10g of washing powder, add 400ml of deionized water, and prepare detergent for degreasing. Put the copper foil in step 1 into the detergent, ultrasonically treat it for 10 minutes, then take it out and wash it with deionized water;

[0105] 3. Take 20ml of concentrated sulfuric acid and prepare it as dilute sulfuric acid with a mass fraction of 5%. Put the copper foil treated in step 2 into the dilute sulfuric acid, pickle it for 10 minutes, and then take it out and wash it with deionized water;

[0106] 4. Weigh 35g of zinc sulfate, 3.5g of DL-sodium malate and 5g of zinc powder into deionized water to prepare 200mL of activator for the preparation of embedded thin film resistors, heat the activator to 40°C, and then...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com