Preparation method of nickel cobalt lithium manganate composite anode material

A composite positive electrode material, nickel-cobalt-lithium manganese oxide technology, applied in the direction of battery electrodes, electrical components, circuits, etc., can solve the problems of increasing safety hazards, unfavorable cycle performance and safety performance, increasing the cost of ternary material preparation, etc., to achieve improvement Effects of cycle performance, improvement of bulk density, and improvement of safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Take 90g of prepared nickel-cobalt lithium manganese oxide doped with metal ions as the matrix, take 10g of fine powder produced in the production process of lithium manganate as the coating material, take 0.5g of boric acid as the binder, and use a horizontal ball mill to mix evenly to get the mixture. The mixture was put into a muffle furnace and sintered in an air atmosphere. The temperature was raised to 600°C for 3 hours, then the temperature was raised to 900°C for 2 hours, and then cooled naturally. A universal pulverizer is used to pulverize and sieve the material to obtain a nickel-cobalt-lithium manganate composite cathode material.

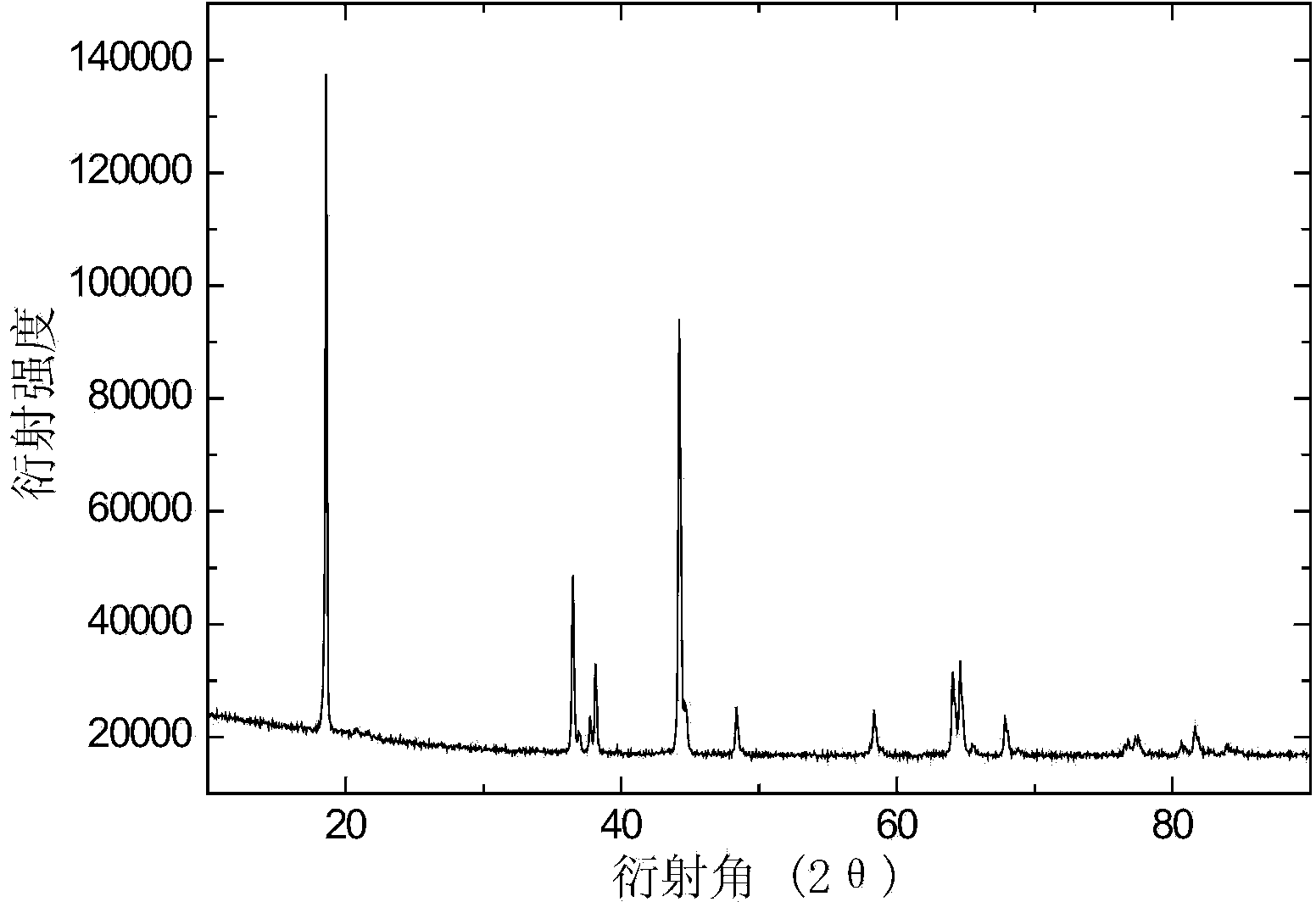

[0017] The material X-ray diffraction pattern that present embodiment obtains, as figure 1 As shown, it can be seen from the characteristic peaks of the X-ray diffraction pattern that the nickel-cobalt-lithium-manganese-oxide composite positive electrode material is a symbiotic state of two lattice structures.

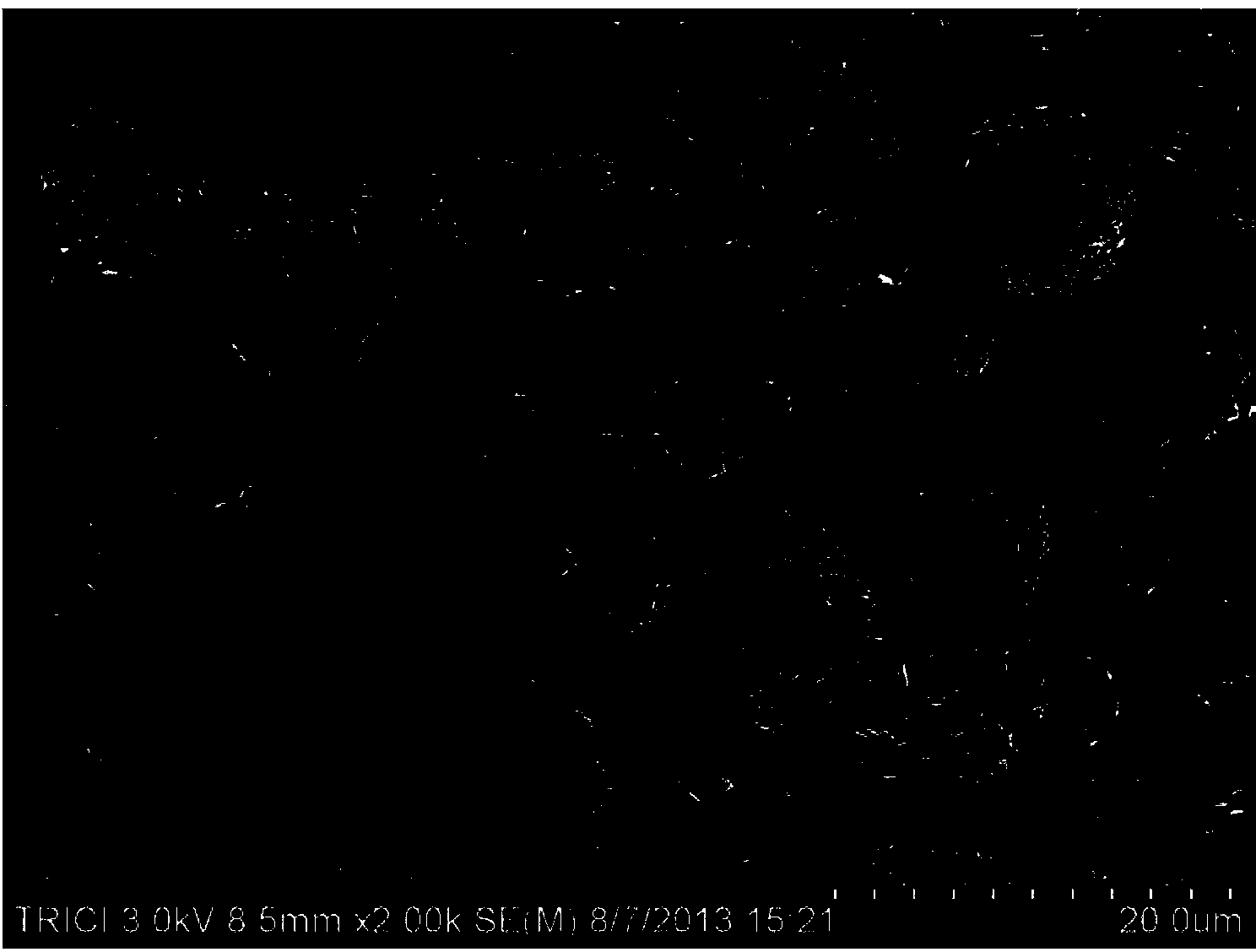

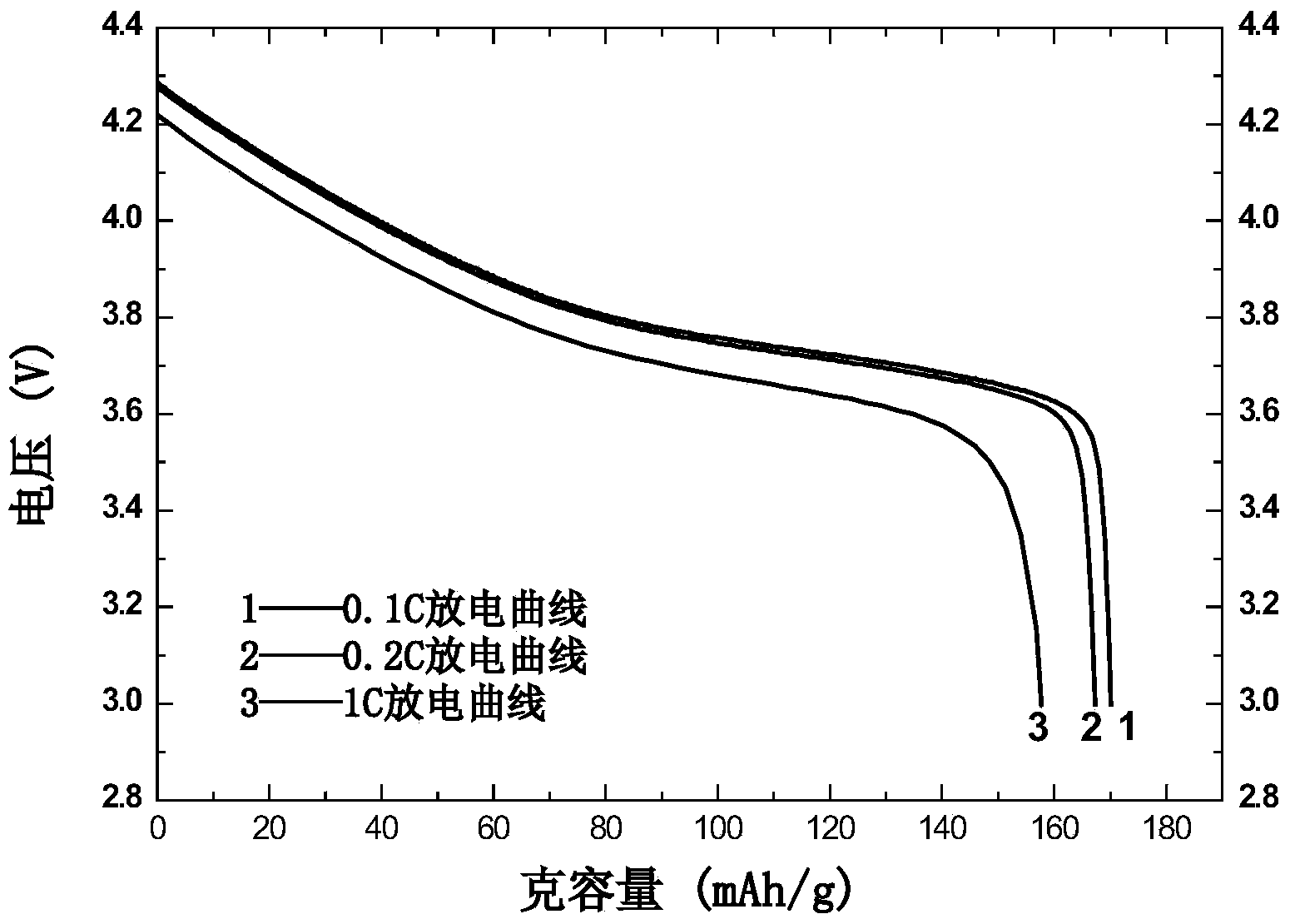

[0018] The mate...

Embodiment 2

[0021] Take the prepared 1800g of nickel-cobalt lithium manganese oxide as the substrate, take 20g of the fine powder produced in the production process of lithium manganate as the coating material, take 60g of barium oxide as the binder, and use a high-speed mixer to mix evenly to obtain a mixture. The mixture was put into a muffle furnace and sintered in an oxygen atmosphere. The temperature was raised to 700°C for 10 hours at a constant temperature, and then the temperature was raised to 1000°C for 10 hours at a constant temperature, and then cooled naturally. A horizontal ball mill is used to pulverize and sieve the material to obtain a nickel-cobalt-lithium manganate composite cathode material.

Embodiment 3

[0023] Take the prepared 700g of nickel-cobalt lithium manganate doped with metal ions as the substrate, take the fine powder produced in the production process of 300g of lithium manganate as the coating material, take 20g of lithium dihydrogen phosphate and 30g of tungsten oxide as the binding agent, Use a horizontal ball mill to mix evenly to obtain a mixture. The mixture was put into a muffle furnace and sintered in an oxygen atmosphere. The temperature was raised to 350°C for 18 hours, then the temperature was raised to 800°C for 20 hours, and then cooled naturally. A universal pulverizer is used to pulverize and sieve the material to obtain a nickel-cobalt-lithium manganate composite cathode material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com