Polychloroprene adhesive and preparation method thereof

A chloroprene adhesive and chloroprene rubber technology, applied in chloroprene adhesives, adhesives, adhesive types, etc., can solve problems such as environmental and human health hazards, continuous release of formaldehyde, etc., and meet environmental protection requirements , The effect of long-lasting action time and high capture efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

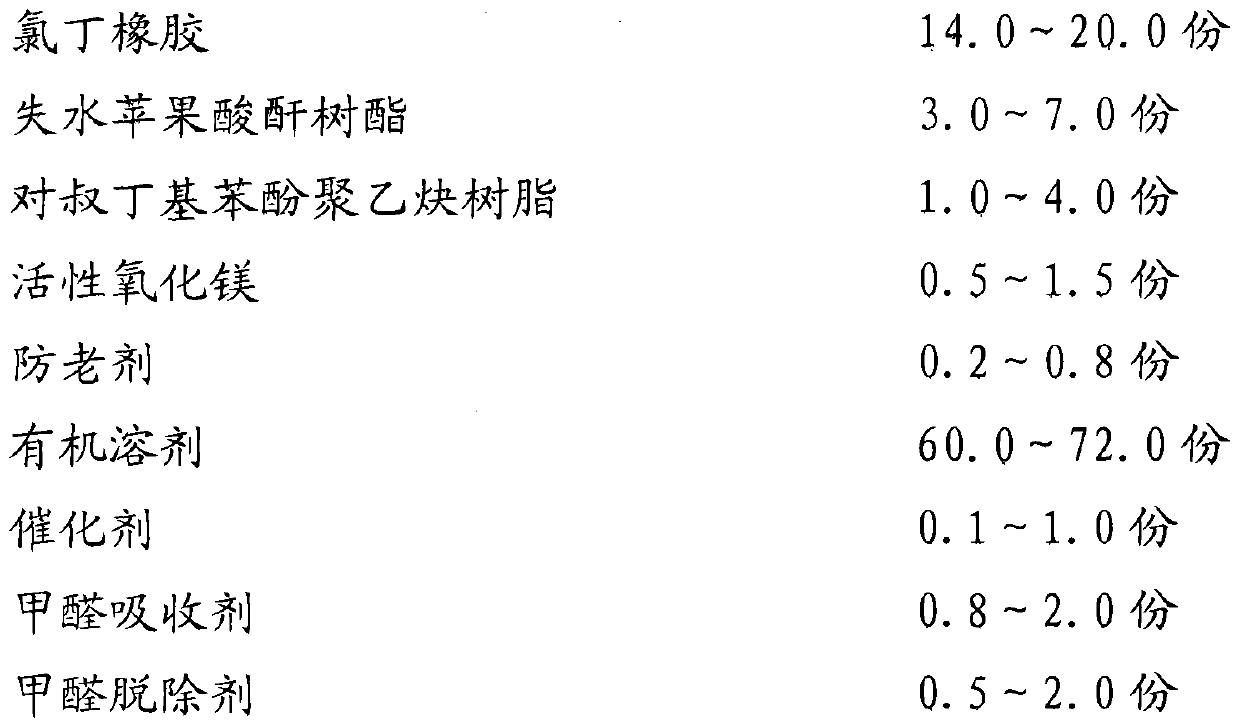

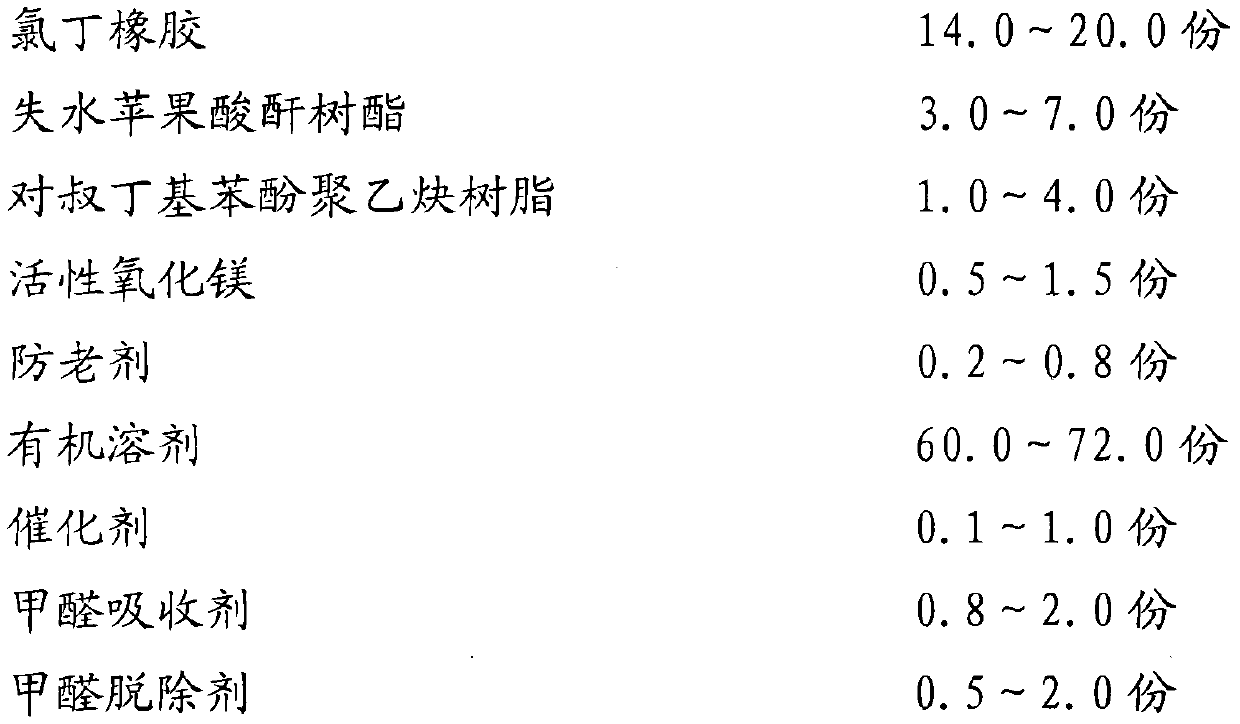

Method used

Image

Examples

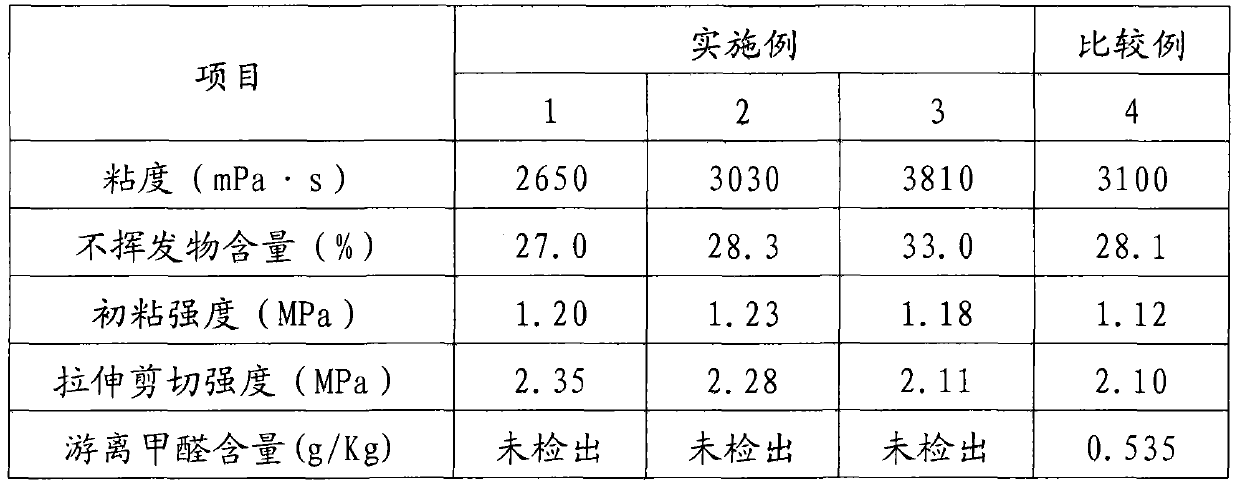

Embodiment 1

[0023] 1. Add 5.0 parts of methylcyclopentane, 30.0 parts of 6# solvent gasoline, 15.0 parts of ethyl acetate, and 10.0 parts of dimethyl carbonate into the high-speed reaction kettle according to the weight ratio of the formula, start the motor to stir, and stir at 150 rpm At the stirring speed per minute, add 3.0 parts of dehydrated malic anhydride resin and 3.0 parts of p-tert-butylphenol polyacetylene resin, stir for 60 minutes until completely dissolved, add 0.5 parts of high-activity magnesium oxide and 0.1 parts of water, at 800 rpm Add 14.0 parts of CR2442, 0.2 parts of ODA, 0.72 parts of ultra-fine fly ash, 0.08 parts of nano-anion powder, 0.25 parts of ammonium persulfate, and 0.25 parts of chitin at a stirring speed of 1 minute, and stir for 6 to 8 hours until completely dissolved. Filtrate the material to obtain neoprene adhesive.

Embodiment 2

[0025] According to the formula weight ratio, add 14.0 parts of methylcyclopentane, 20.0 parts of 6# solvent gasoline, 21.0 parts of ethyl acetate, and 17.0 parts of dimethyl carbonate into the high-speed reactor, start the motor to stir, at 100 rpm At the stirring speed, add 5.0 parts of dehydrated malic anhydride resin, 4.0 parts of p-tert-butylphenol polyacetylene resin, stir for 30 minutes until completely dissolved, add 1.0 parts of high-activity magnesium oxide and 0.6 parts of isopropanolamine, at 900 rpm Add 15.0 parts of A90, 0.6 parts of KY4055, 0.1 parts of superfine fly ash, 0.9 parts of nano-anion powder, 1.0 parts of sodium persulfate, and 0.2 parts of chitin at the stirring speed per minute, and stir for 6 to 8 hours until completely dissolved , and filter the material to obtain neoprene adhesive.

Embodiment 3

[0027] According to the formula weight ratio, add 10.0 parts of methylcyclopentane, 24.0 parts of 6# solvent gasoline, 24.0 parts of ethyl acetate, and 12.0 parts of dimethyl carbonate into the high-speed reactor, start the motor to stir, at 120 rpm Under stirring speed, add 7.0 parts of dehydrated malic anhydride resin, 1.0 parts of p-tert-butylphenol polyacetylene resin, stir for 45 minutes until completely dissolved, add 1.5 parts of high-activity magnesium oxide, 1.0 parts of N-methyl-2-pyrrolidone , at a stirring speed of 1000 rpm, add 20.0 parts of A90, 0.8 parts of 4010NA, 1.0 parts of ultra-fine fly ash, 1.0 parts of nano-anion powder, 0.5 parts of ammonium persulfate, 0.4 parts of potassium persulfate, and 0.2 parts of chitin part, stirred for 8 hours until completely dissolved, and filtered out to obtain neoprene adhesive.

PUM

| Property | Measurement | Unit |

|---|---|---|

| peel strength | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com