Negative photoresist stripper composition

A photoresist and stripping agent technology, applied in the direction of photosensitive material processing, can solve problems affecting product quality, wiring material corrosion, etc., and achieve the effect of excellent stripping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

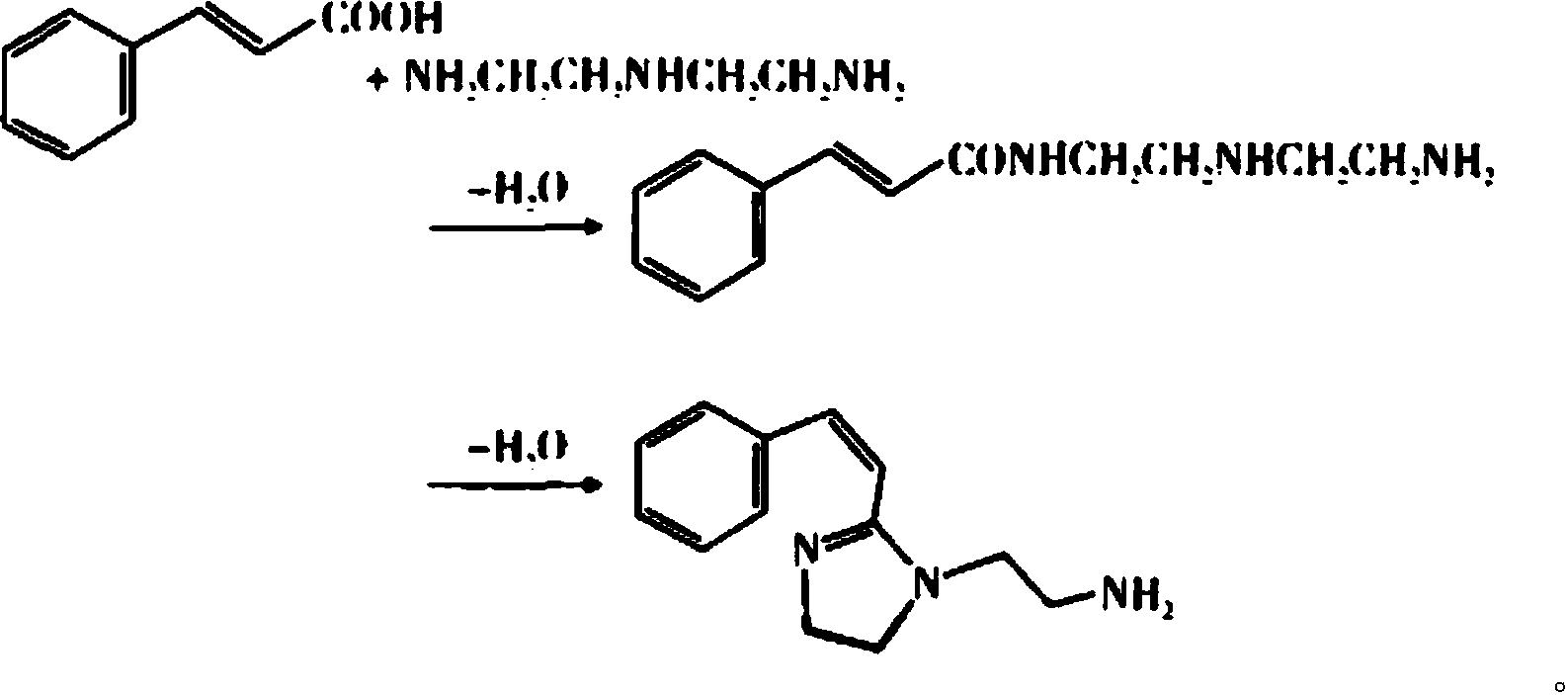

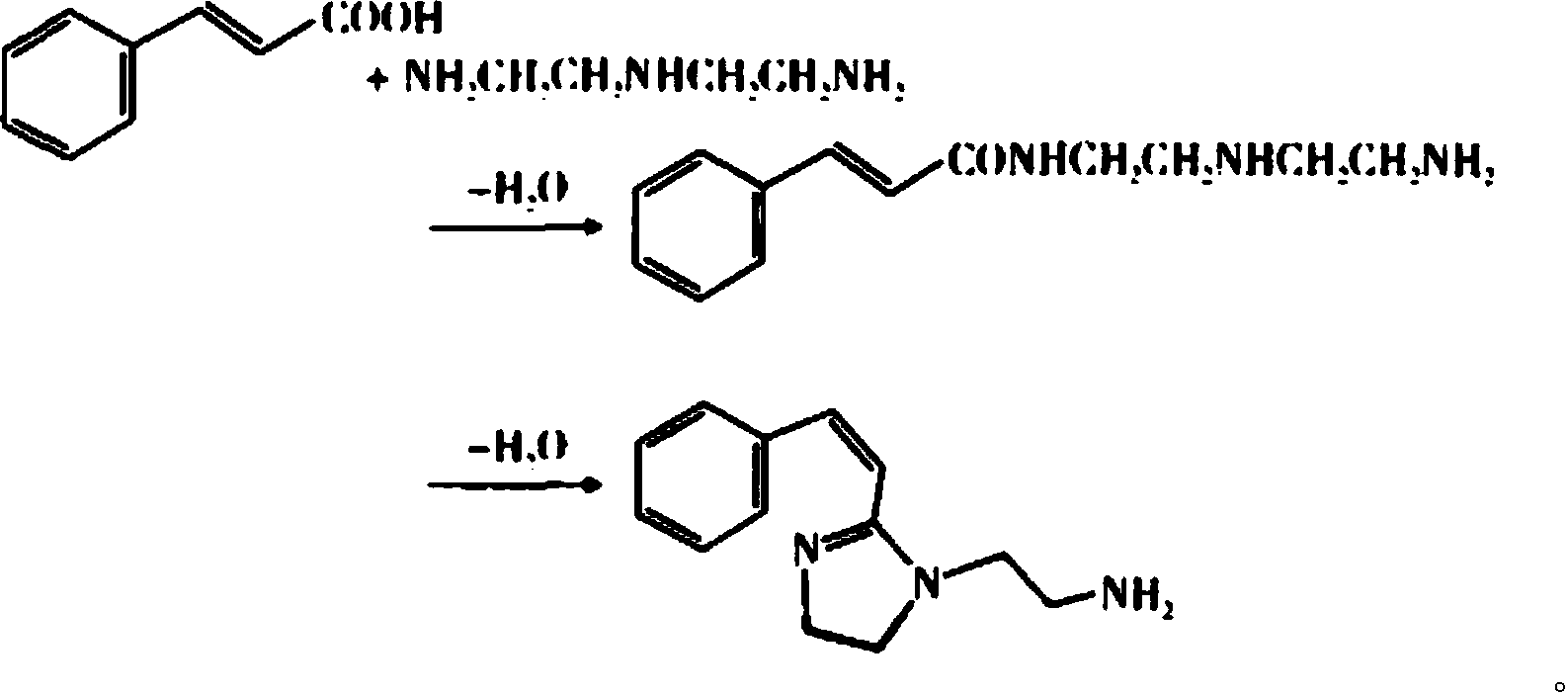

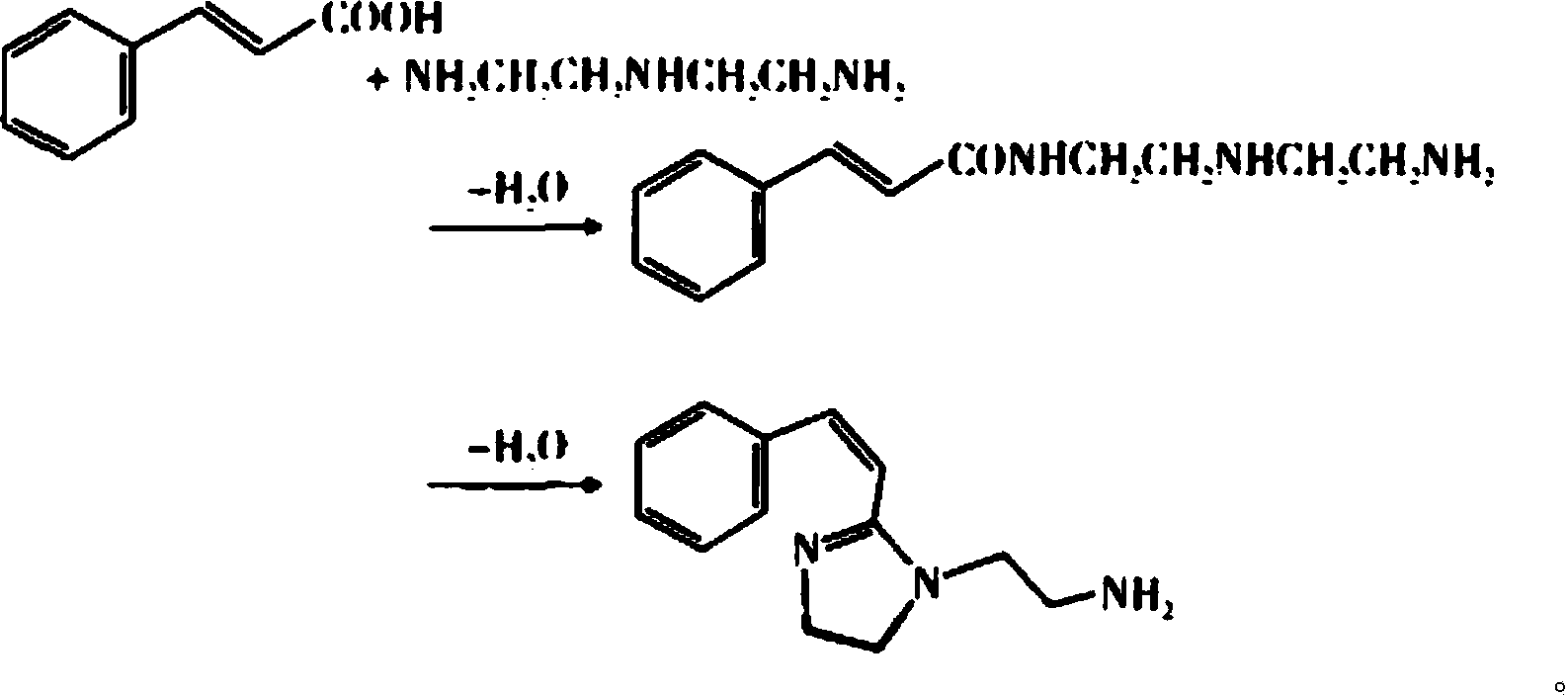

[0037] The preparation method of described cinnamyl imidazoline is specifically:

[0038] Put 10ml of analytically pure diethylenetriamine in a four-necked flask, raise the temperature to 150°C, add 3ml of analytically pure toluene dropwise, add 22g of analytically pure cinnamic acid, stir under a nitrogen atmosphere, and then raise the temperature to 170°C to start acyl After reaction for 5 hours, the temperature was raised to 240°C to start cyclodehydration for 3 hours. After the reaction was completed, it was placed in a vacuum drying oven to dry to obtain cinnamyl imidazoline in a brown viscous shape. The reaction formula is as follows:

[0039]

[0040] The preparation method of the 1,3-bis(2-benzimidazolyl)-2-oxapropane is specifically:

[0041] Take 10.8g of o-phenylenediamine and 7g of diglycolic acid, mix and dissolve them in 120ml of hydrochloric acid solution with a concentration of 6mol / L, stir mechanically, and reflux at 90°C for 12h. After the system is cooled...

Embodiment 1

[0044] The preparation of embodiment 1 cinnamyl imidazoline

[0045] Put 10ml of analytically pure diethylenetriamine in a four-necked flask, raise the temperature to 150°C, add 3ml of analytically pure toluene dropwise, add 22g of analytically pure cinnamic acid, stir under nitrogen, and then heat up to 170°C to start acyl After 5 hours of reaction, the temperature was raised to 240° C. to start cyclodehydration for 3 hours. After the reaction was completed, it was placed in a vacuum oven to dry to obtain cinnamyl imidazoline in a brown viscous shape.

Embodiment 21

[0046] Embodiment 21, the preparation of 3-bis(2-benzimidazolyl)-2-oxapropane

[0047] Take 10.8g of o-phenylenediamine and 7g of diglycolic acid, mix and dissolve them in 120ml of hydrochloric acid solution with a concentration of 6mol / L, stir mechanically, and reflux at 90°C for 12h. After the system is cooled, adjust the pH with ammonia water value until the solution is weakly alkaline, cool, dry, and recrystallize (50mL×3 times) with water-acetone (volume ratio 1:1) to obtain the target product in white powder form, which is 1,3-bis(2-benzene and imidazolyl)-2-oxapropane.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com