Rectangular plane cathode arc source and cathode target material ablation device

A planar cathode and cathode target technology, which is applied in the metal material coating process, ion implantation plating, coating, etc., can solve the problems of high heating on the surface of the cathode target, complex device structure, and difficult scanning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0061] Example 1: Preparation of chromium nitride thin film under the control of permanent magnet magnetic field

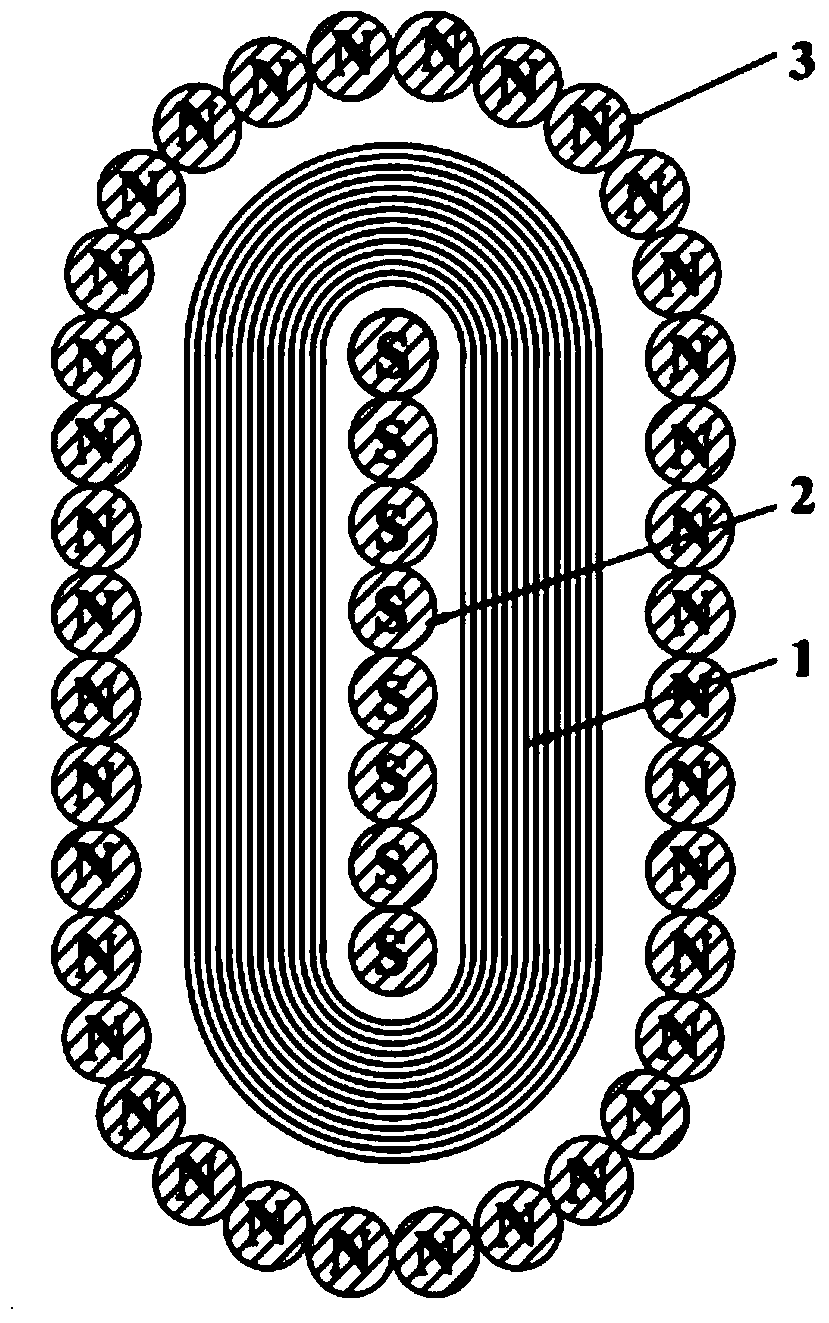

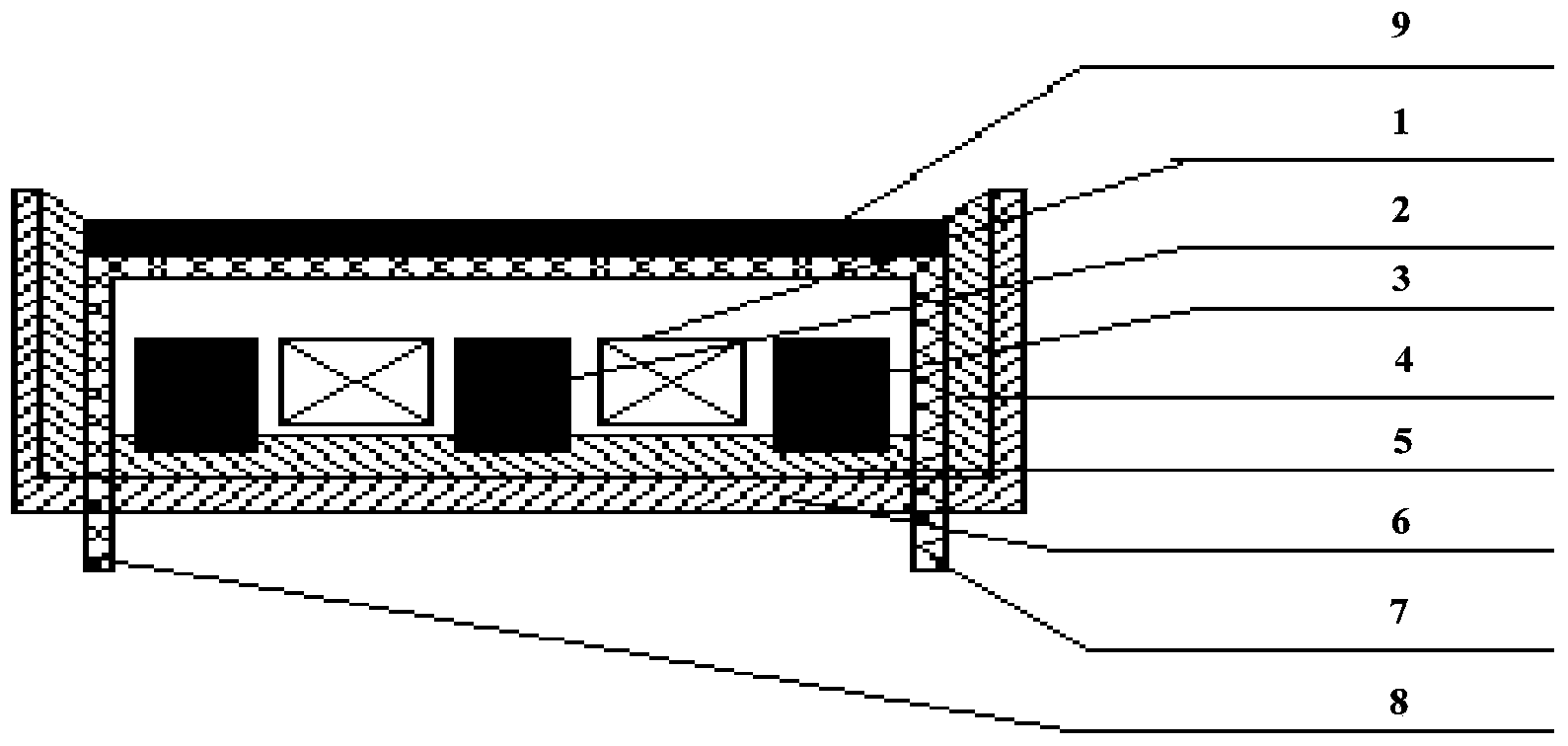

[0062] based on figure 1 The arc source structure shown is controlled by a permanent magnet magnetic circuit, using such as Figure 4 The shown device carries out the technology of cathodic arc deposition chromium nitride film and prepares the experiment, and its operation steps are as follows:

[0063] 1) Cleaning of parts

[0064] Clean the parts ultrasonically with acetone for 30 minutes, dry them with a hair dryer, put them in a vacuum chamber, pump them down to 0.004Pa, let in argon gas, adjust the argon gas flow rate to 8 sccm, control the air pressure at 0.08Pa, turn on the gas ion source, and carry out Argon ion bombardment cleaning, the cleaning time is controlled at 45min.

[0065] 2) Preparation of Cr transition layer

[0066] Adjust the argon gas flow rate to 50sccm, control the air pressure at 0.6Pa, manually adjust the distance between the cathod...

example 2

[0069] Example 2: Preparation of titanium nitride thin films under the control of the composite magnetic field of permanent magnets and electromagnetic coils

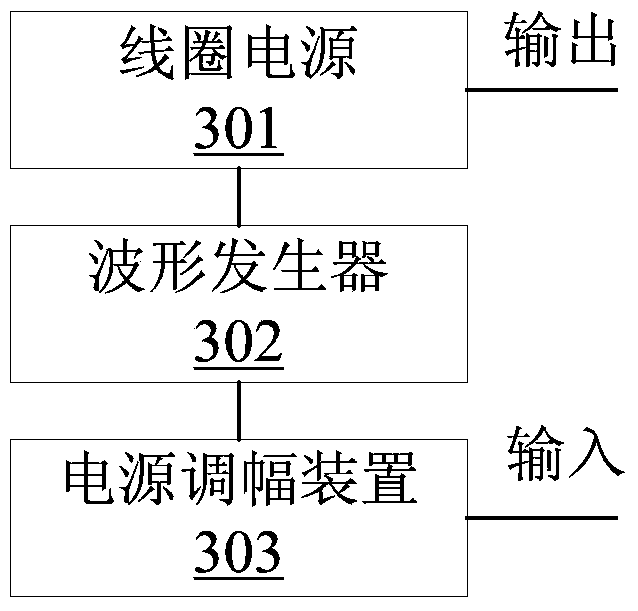

[0070] based on figure 1 The shown arc source structure adopts the combined magnetic circuit control method of permanent magnet group and electromagnetic coil. Figure 6 The shown device carries out the preparation experiment of the technique of depositing titanium nitride film by cathodic arc method, and its operation steps are as follows:

[0071] 1) Cleaning of parts

[0072] Clean the parts ultrasonically with acetone for 30 minutes, dry them with a hair dryer, put them in a vacuum chamber, pump them down to 0.004Pa, let in argon gas, adjust the argon gas flow rate to 8 sccm, control the air pressure at 0.08Pa, turn on the gas ion source, and carry out Argon ion bombardment cleaning, the cleaning time is controlled at 45min.

[0073] 2) Preparation of Ti transition layer

[0074] Adjust the argon gas flow rate to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com