Porous carbon-based solid acid catalyst and preparation method thereof

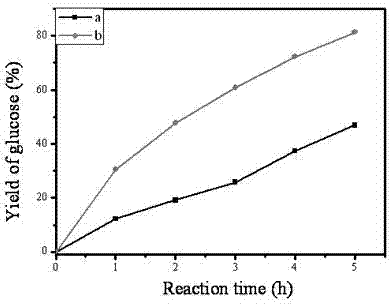

A solid acid catalyst, carbon-based solid acid technology, applied in the field of material science, can solve the problems of low exposure of active centers, poor catalytic activity, etc., achieve excellent catalytic performance, simple and effective method, and improve the effect of specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] First, using ethanol as solvent and F127 as template to synthesize mesoporous sulfonate-functionalized nanoporous carbon catalytic materials.

[0031] Add 1.6 g of F127 to 25 g of absolute ethanol to dissolve, then add 5.0 g of furfural, then add 3.5 g of isethionic acid, stir for 30 minutes, transfer the reaction mixture to a petri dish and volatilize at room temperature for 24 hours to obtain a reddish-brown membrane material , bake the above material at 100 degrees Celsius for 24 hours, then transfer to 180 degrees Celsius and bake for 24 hours to get MC-SO 3 H initial product. MC-SO 3 The initial product of H is dispersed in 50 ml of ethanol and 7 ml of concentrated hydrochloric acid mixed solution, and refluxed at 90 degrees Celsius for 24 hours to obtain MC-SO4 with open channels. 3 H material.

Embodiment 2

[0033] Mesoporous sulfonate-functionalized nanoporous carbon catalytic materials were synthesized with ethanol as solvent and F127 as template, and the synthesis temperature was changed.

[0034] Add 1.6 g of F127 to 25 g of absolute ethanol to dissolve, then add 5.0 g of furfural, then add 3.5 g of isethionic acid, stir for 30 minutes, transfer the reaction mixture to a petri dish and volatilize at room temperature for 24 hours to obtain a reddish-brown membrane material , bake the above material at 120 degrees Celsius for 24 hours, then transfer to 160 degrees Celsius and bake for 24 hours to get MC-SO3 H initial product. MC-SO 3 The initial product of H is dispersed in 50 ml of ethanol and 7 ml of concentrated hydrochloric acid mixed solution, and refluxed at 90 degrees Celsius for 24 hours to obtain MC-SO4 with open channels. 3 H material.

Embodiment 3

[0036] Firstly, tetrahydrofuran was used as solvent and P123 was used as template to synthesize mesoporous sulfonate-functionalized nanoporous carbon catalyst materials.

[0037] 1.6 g of P123 was dissolved in 25 g of tetrahydrofuran, then 5.0 g of furfural was added, followed by 3.5 g of isethionic acid, and after stirring for 30 minutes, the reaction mixture was transferred to a petri dish and volatilized at room temperature for 24 hours to obtain a reddish-brown membrane material. Bake the above materials at 100 degrees Celsius for 24 hours, then transfer them to 180 degrees Celsius and bake them for 24 hours to get MC-SO 3 H initial product. MC-SO 3 The initial product of H is dispersed in 50 ml of ethanol and 7 ml of concentrated hydrochloric acid mixed solution, and refluxed at 90 degrees Celsius for 24 hours to obtain MC-SO4 with open channels. 3 H material.

PUM

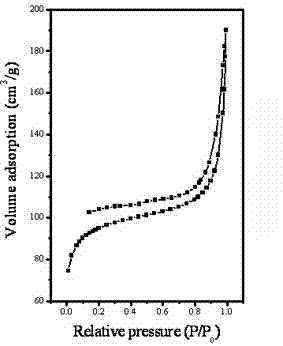

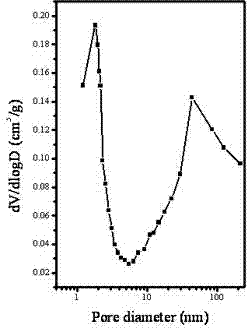

| Property | Measurement | Unit |

|---|---|---|

| pore size distribution | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com