Preparation method of polyoxy methylene dimethyl ether

A technology of polyoxymethylene dimethyl ether and dimethyl ether, which is applied in the field of preparation of polyoxymethylene dimethyl ether, can solve problems such as catalyst corrosion, achieve improved activity and stability, and high crystallinity Internal diffusion rate, reducing the effect of depth reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

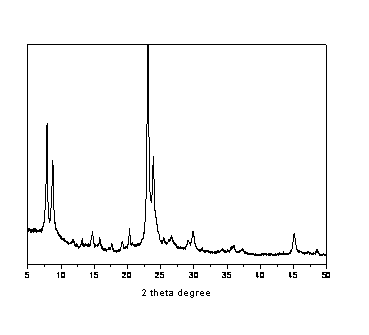

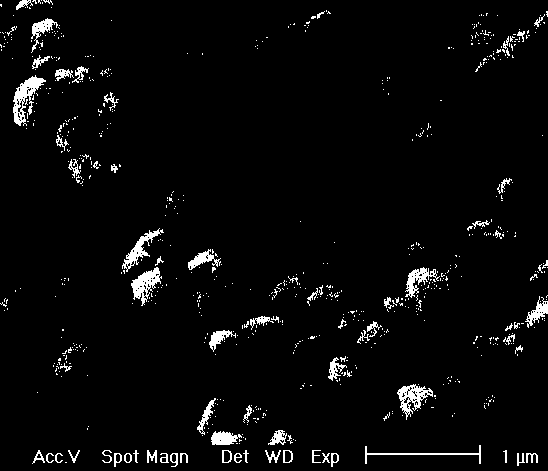

[0027] Mix 40% silica sol, sodium metaaluminate, tetrabutylammonium bromide, sodium chloride, sodium hydroxide and water, stir for 20 minutes, put into a reaction kettle, and crystallize at 170°C for 1 day. The crystallized product was quenched, filtered, and washed with water until the pH value was 8, and dried at 120°C for 12 hours to obtain the original powder of ZSM-11 molecular sieve. The XRD spectrum is shown in figure 1 , SEM photo see figure 2 , the grain diameter is 0.5 microns. The molar ratio of each raw material in the reaction mixture is: SiO 2 / Al 2 o 3 =149.3,H 2 O / SiO 2 =32.8, NaCl / SiO 2 =0.6, NaOH / SiO 2 =0.08, TBABr / SiO 2 =0.12.

[0028] The synthesized ZSM-11 molecular sieve raw powder was treated with 0.3 mol / L nitric acid at 80°C for 4 hours for 3 consecutive times to obtain HZSM-11.

[0029] Mix HZSM-11 with boehmite, Tianqing powder, and 0.3 mol / liter nitric acid, and the weight ratio of each raw material is ZSM-11 / Al 2 o 3 / Tianqing powder = ...

Embodiment 2

[0033] Mix 40% silica sol, sodium metaaluminate, tetrabutylammonium bromide, sodium chloride, sodium hydroxide and water, stir for 20 minutes, put into a reaction kettle, and crystallize at 170°C for 1 day. The crystallized product was quenched, filtered, washed with water until the pH value was 8, and dried at 120°C for 12 hours to obtain ZSM-11 molecular sieve raw powder with a grain diameter of 0.5 microns. The molar ratio of each raw material in the reaction mixture is: SiO 2 / Al 2 o 3 =149.3,H 2 O / SiO 2 =32.8, NaCl / SiO 2 =0.6, NaOH / SiO 2 =0.08, TBABr / SiO 2 =0.12.

[0034] The synthesized ZSM-11 molecular sieve raw powder was treated with 0.3 mol / L hydrochloric acid at 80°C for 4 hours for 3 consecutive times to obtain HZSM-11.

[0035] Mix HZSM-11 with boehmite, Tianqing powder, and 0.3 mol / liter nitric acid, and the weight ratio of each raw material is HZSM-11 / Al 2 o 3 / Tianqing powder = 1:1:0.1, extruded into strips, dried at 120°C for 12 hours, roasted at 55...

Embodiment 3

[0039] According to the steps and conditions of [Example 2], only SiO in the synthetic formula 2 / Al 2 o 3 =52, tetrabutylammonium hydroxide was used as template agent, crystallized at 120° C. for 8 days, and the crystal grain diameter of the synthesized ZSM-11 molecular sieve raw powder was 1 micron. Exchange with 1.0 mol / L citric acid at 80°C for 10 hours. Get a catalyst.

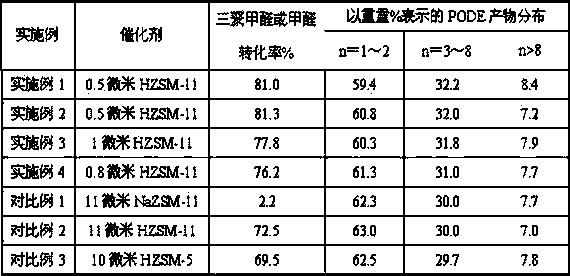

[0040] The performance evaluation of the catalyst was carried out on a 300ml autoclave reaction device. Add 1.2 grams of catalyst, 50 grams of methanol, 50 grams of dimethyl ether, and 100 grams of paraformaldehyde in the autoclave, and react for 5 hours at 100 ° C and a pressure of 1 MPa by filling nitrogen, and filter and separate the catalyst and the reaction product. Chromatographic analysis, the composition of the obtained mixture is shown in Table 1.

[0041]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com