Novel process for treating tea deep processing industrial wastewater

A technology for wastewater treatment and deep processing, which is applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, general water supply conservation, etc. Small, reduce water consumption, reduce the effect of chroma

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

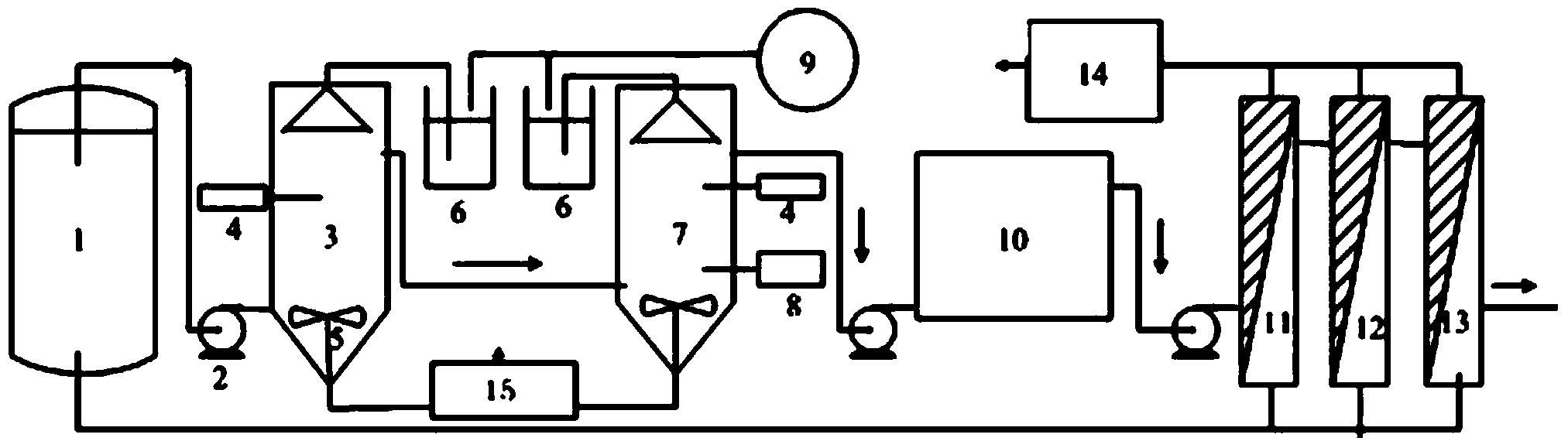

[0034] Example 1. Production wastewater from a tea polyphenols manufacturing plant

[0035] The tea polyphenol wastewater mainly comes from tea cleaning and solvent recovery process. These two kinds of wastewater are transported to the pretreatment tank 1. The temperature of the wastewater is 50~60℃, the content of tea polyphenols is 43.7%, the COD is 28000mg / L, and the SS is 11800mg / L, the chromaticity is 827 times. The waste water is cooled to 30-40°C in the pretreatment tank 1, the pH is adjusted to 5-8, and 500 mg / L polyaluminum chloride and 30 mg / L polyacrylamide are added for flocculation.

[0036]The supernatant after pretreatment and precipitation is sent to the acid production reactor 3 through the centrifugal pump 2, and the pH value of the production reactor 3 is controlled to be 4.2~5.5 (controlled by the pH detector 4); the effluent after the reaction flows into the acid production reactor automatically In the reactor 7, the pH is controlled at 6.5~7.3, and the ...

Embodiment 2

[0039] Compared with Example 1, the only difference is that in step (1) of this example, the flocculant is polyaluminum chloride, and the addition amount is 600 mg / L, and the coagulant aid is polyacrylamide, and the addition amount is 50 mg / L . During the pretreatment process, the temperature was controlled at 35°C, and the pH was controlled at 10 using a pH regulator.

[0040] In step (2), the pH in the acid generating reactor 3 is controlled to be 6, the pH of the methanogenic reactor 7 is controlled to be 10, and the temperature is 40°C. Influent COD load is 3.0kg / m 3 d, the hydraulic retention time of the acid generating reactor 3 is 24h, and the hydraulic retention time of the methanogenic reactor 7 is 4d.

[0041] In the integrated treatment device of ultrafiltration, nanofiltration and reverse osmosis membrane in step (3), the cross-flow velocity of the ultrafiltration membrane for filtering sewage is 1~7m / s, and the operating pressure is 0.5MPa; the operating pressur...

Embodiment 3

[0044] Compared with Example 1, the only difference is that in step (1) of this example, the flocculant is polyferric sulfate, and the addition amount is 200 mg / L, and the coagulation aid is activated silicic acid, and the addition amount is 10 mg / L. During the pretreatment process, the temperature was controlled at 35°C, and the pH was controlled at 4 using a pH regulator.

[0045] In step (2), the pH in the acid generating reactor 3 is controlled to be 4, the pH of the methanogenic reactor 7 is controlled to be 6, and the temperature is 30°C. Influent COD load is 1.0kg / m 3 d, the hydraulic retention time of the acid generating reactor 3 is 12h, and the hydraulic retention time of the methanogenic reactor 7 is 1d.

[0046] In the integrated treatment device of ultrafiltration, nanofiltration and reverse osmosis membrane in step (3), the cross-flow velocity of the ultrafiltration membrane for filtering sewage is 1m / s, and the operating pressure is 0.1MPa; the operating pressu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com