An integrated dry purification method and system for multi-component pollutants in flue gas

A pollutant and multi-component technology, applied in the field of flue gas purification, can solve the problems of complex process, different removal mechanism, high investment cost and saline wastewater, and achieve the effect of simple steps, high purification efficiency and short process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

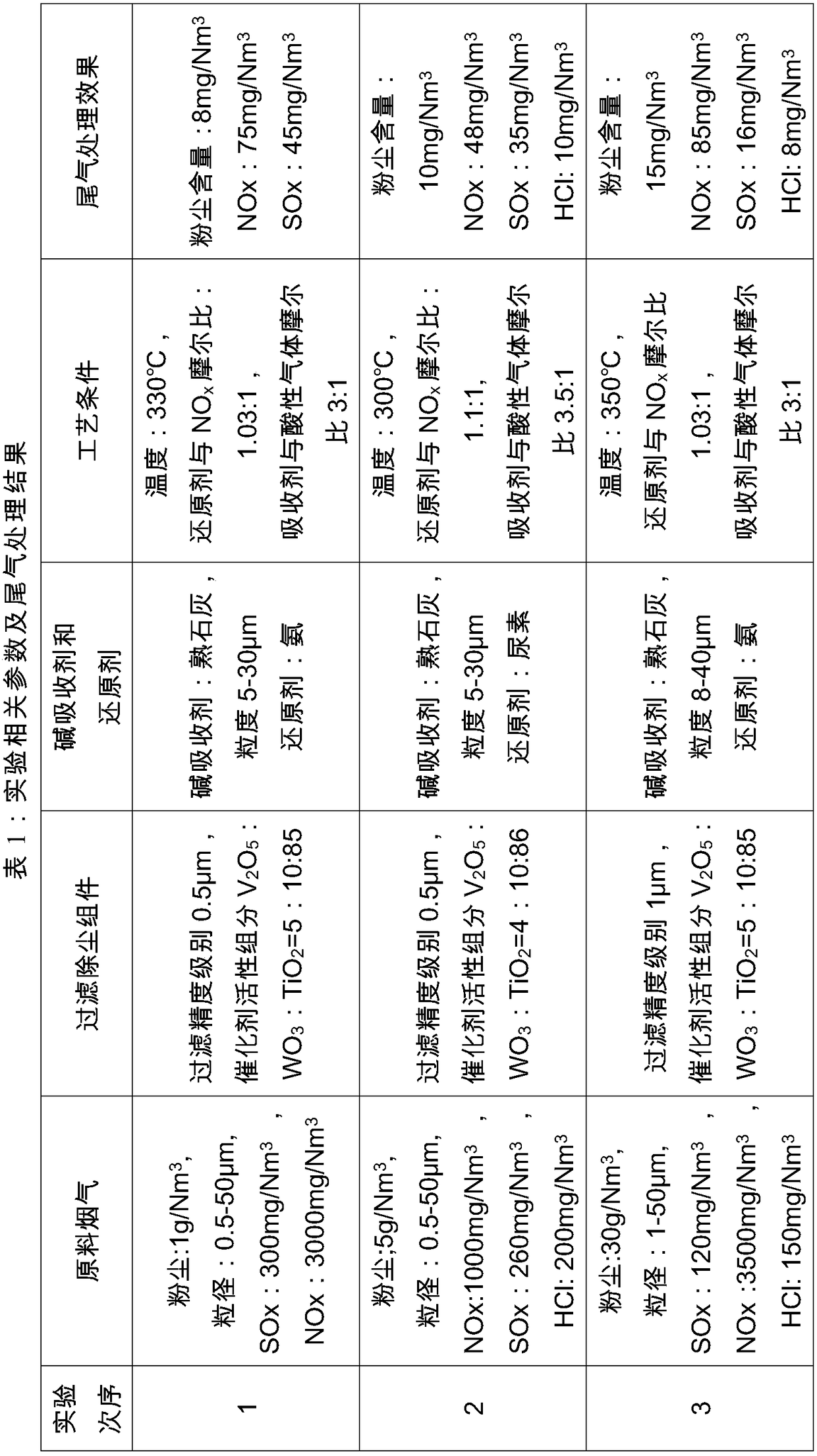

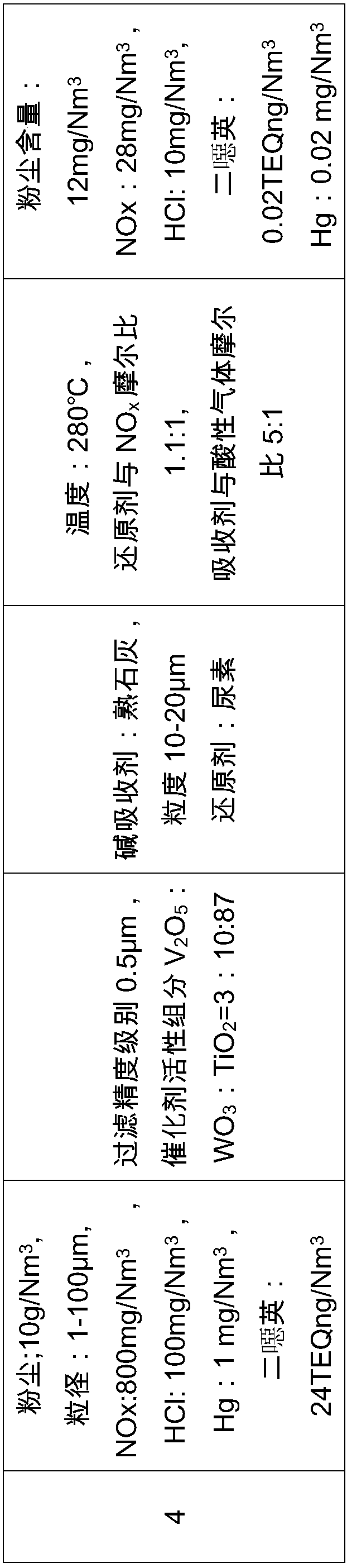

Examples

Embodiment 1

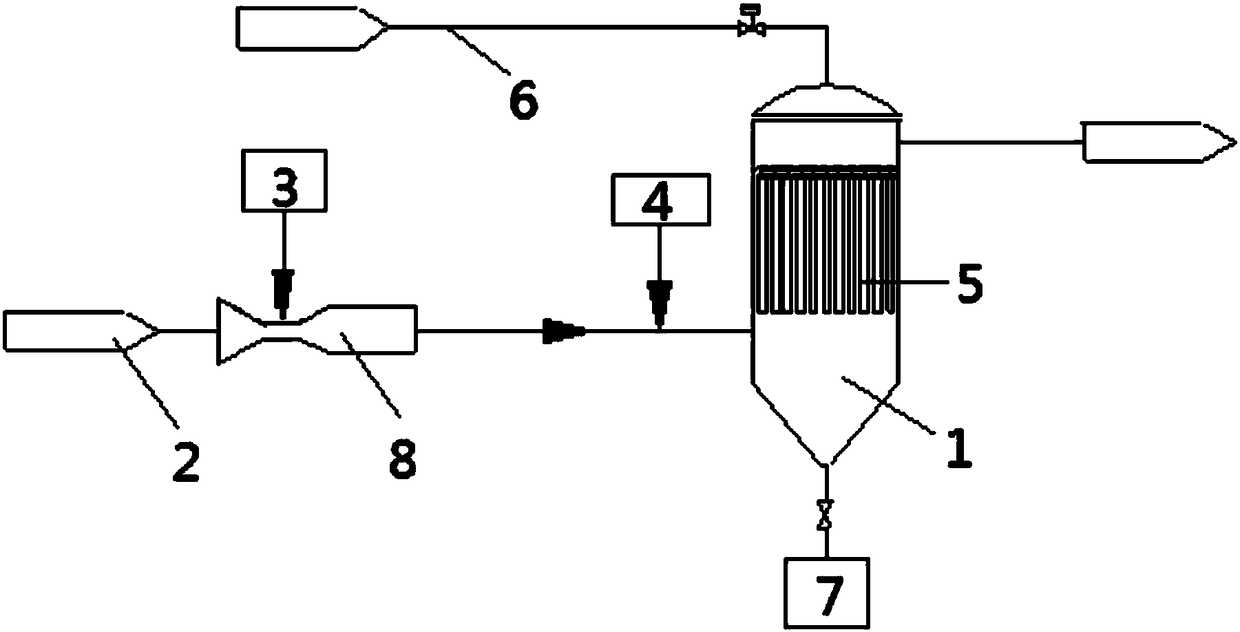

[0046] Embodiment 1 discloses an integrated dry purification method for flue gas multi-component pollutants, including steps:

[0047] S10: Add an alkali absorbent to the flue gas, the alkali absorbent and the acid gas (such as HCL, SO2) in the flue gas X ) reaction, and adsorb dioxins and gaseous metals, etc., to obtain the first flue gas, which includes soot, nitrogen oxides and alkaline particle absorbents;

[0048] S20: Add a reducing agent to the first flue gas to obtain a second flue gas, and the second flue gas includes soot, nitrogen oxides, an alkaline particle absorbent, and a reducing agent;

[0049] S30: Make the second flue gas pass through the SCR-FI catalytic filter assembly, the soot and alkaline particle absorbent in the second flue gas are intercepted on the surface of the SCR-FI catalytic filter assembly, the second The reducing agent and nitrogen oxides in the flue gas undergo a denitrification reaction in the SCR-FI catalytic filter assembly to generate n...

Embodiment 2

[0053] Compared with Embodiment 1, the method for integrated dry purification of flue gas multi-component pollutants in Embodiment 2 further includes step S50: collecting the soot and alkaline particle absorbent on the surface of the SCR-FI catalytic filter assembly.

[0054] By regularly collecting the soot and alkaline particle absorbent on the surface of the SCR-FI catalytic filter assembly, the SCR-FI catalytic filter assembly can be effectively cleaned, thereby ensuring the catalytic filtration effect of the SCR-FI catalytic filter assembly to a certain extent.

Embodiment 3

[0056] Compared with Example 1, the improvement of the integrated dry purification method for flue gas multi-component pollutants in Example 3 lies in:

[0057] In step S10, when the alkali absorbent is added to the flue gas, the molar ratio of the alkali absorbent to the acid gas in the flue gas is 2:1˜5:1. If the molar ratio of the alkali absorbent to the acid gas in the flue gas is too small, it is not conducive to the complete absorption of acid gas, dioxin, gaseous mercury and other gaseous metals, etc. If the ratio is too large, it will not only increase the absorption of the injected alkali The power consumption of the agent will increase the load of the SCR-FI catalytic filter assembly in the subsequent processing steps and reduce its operating life.

[0058] In step S10: passing the flue gas through a Venturi distributor, adding an alkali absorbent to the flue gas from the throat of the Venturi distributor, so that the alkali absorbent and the flue gas are uniformly m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com