Continuous preparation method for preparing hexamethoxyl methyl melamine resin through continuous process

A technology of hexamethoxymethylmelamine and continuous method, which is applied in the field of continuous preparation of hexamethoxymethylmelamine resin by continuous method, can solve the problems of long production cycle, low degree of methyl etherification, high product viscosity, etc., and achieve operation Fewer personnel, no three wastes, high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

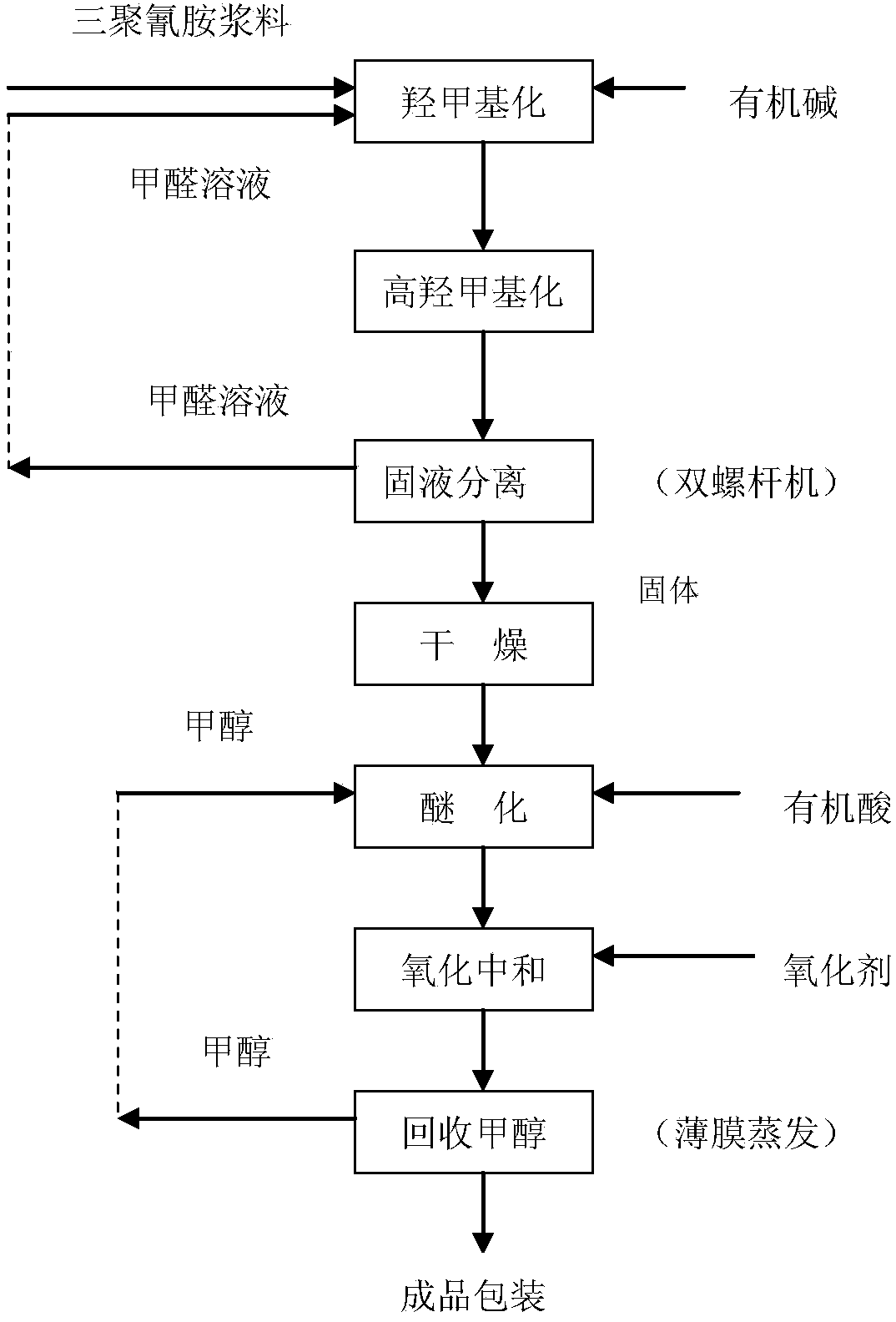

Method used

Image

Examples

Embodiment 1

[0030] 1) The configuration of melamine and methanol (or formalin, or aldol composite solution) slurry:

[0031] A component melamine slurry, put 335g melamine and 390g methanol into a 1 liter four-necked flask, beat at normal temperature, and set aside;

[0032] 2) Formalin solution configuration:

[0033] For component B formaldehyde solution, configure formaldehyde solution with a concentration of 45% (concentration can be between 25-65% according to needs). If the concentration is too low, you can use paraformaldehyde to depolymerize to prepare a formaldehyde solution with a suitable concentration for use;

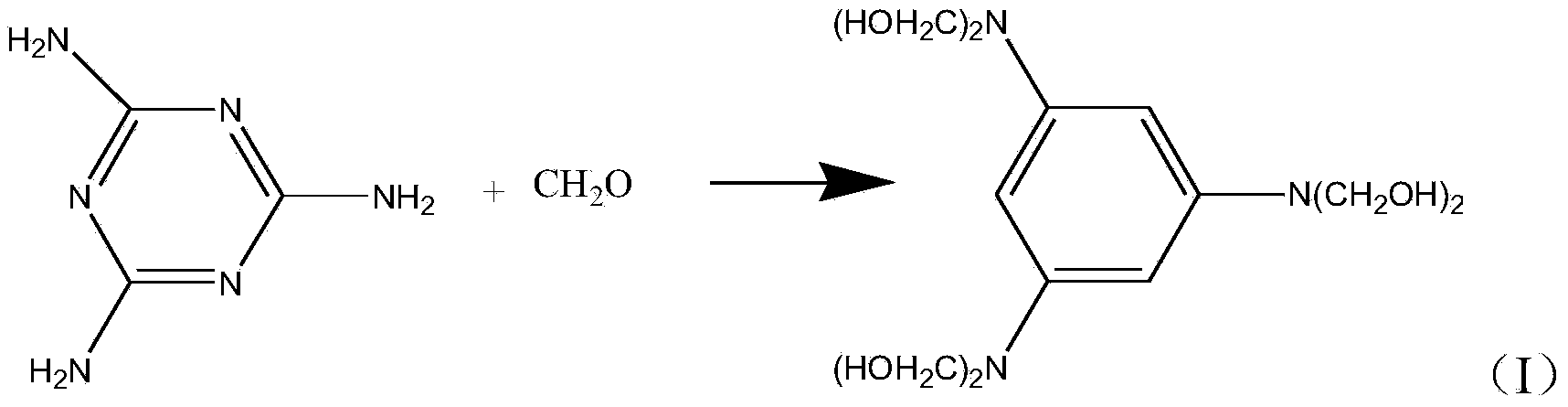

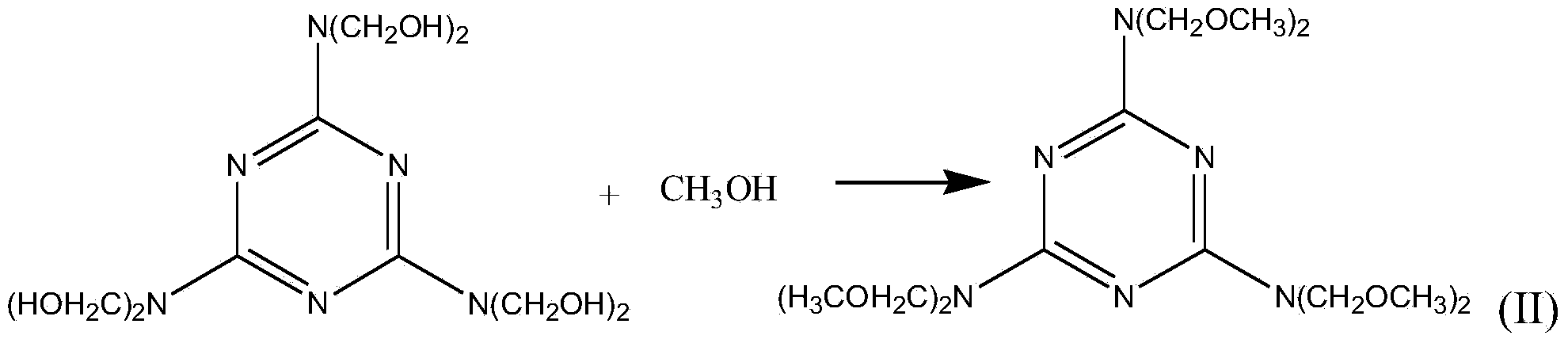

[0034] 3) Hydroxymethylation reaction: Put A and B components into the methylolation reactor according to A:B=1:1.5 (weight ratio), add a certain amount of triethylamine (or other amines compound), control the reaction temperature at 45-85°C, pH=7.5-10.0, and the reaction time for 10-90 minutes to obtain low methylolated melamine, continue the methylolation reaction, ...

Embodiment 2

[0044] 1) The configuration of melamine and methanol (or formalin, or aldol composite solution) slurry:

[0045] A component melamine slurry, put 33.5kg melamine and 450kg methanol into a 1000-liter reactor, beat at normal temperature, and set aside;

[0046] 2) Formalin solution configuration:

[0047] For component B formaldehyde solution, configure formaldehyde solution with a concentration of 45% (concentration can be between 25-65% according to needs). If the concentration is too low, you can use paraformaldehyde to depolymerize to prepare a formaldehyde solution with a suitable concentration for use;

[0048] 3) Hydroxymethylation reaction: Put A and B components into the continuous methylolation reactor according to A:B=1:1.5 (weight ratio), add a certain amount of triethylamine (or other amines compound), control the reaction temperature at 45-85°C, pH value 7.5-10.0, and reaction time 10-90 minutes to obtain low methylolated melamine, and pump low methylolated melami...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Acid value | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com