Method for preparing collagen microfiber by use of ionic liquid mixing solvent

A technology of ionic liquids and mixed solvents, which is applied in the chemical post-treatment of fibers, fiber treatment, animal raw materials, etc., can solve problems such as difficulties, and achieve the effects of high utilization rate, wide range of sources, and simple reaction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The first step is to mix [Emim]Cl with dimethyl sulfoxide ([Emim]Cl concentration 80vol%) to make a treatment reagent.

[0024] Step 2: Add 0.5 g of dried pigskin powder into a reactor equipped with 50 ml of treatment agent, stir mechanically (500 rpm), and treat at 130° C. for 10 hours under nitrogen protection to prepare a suspension containing collagen microfibrils.

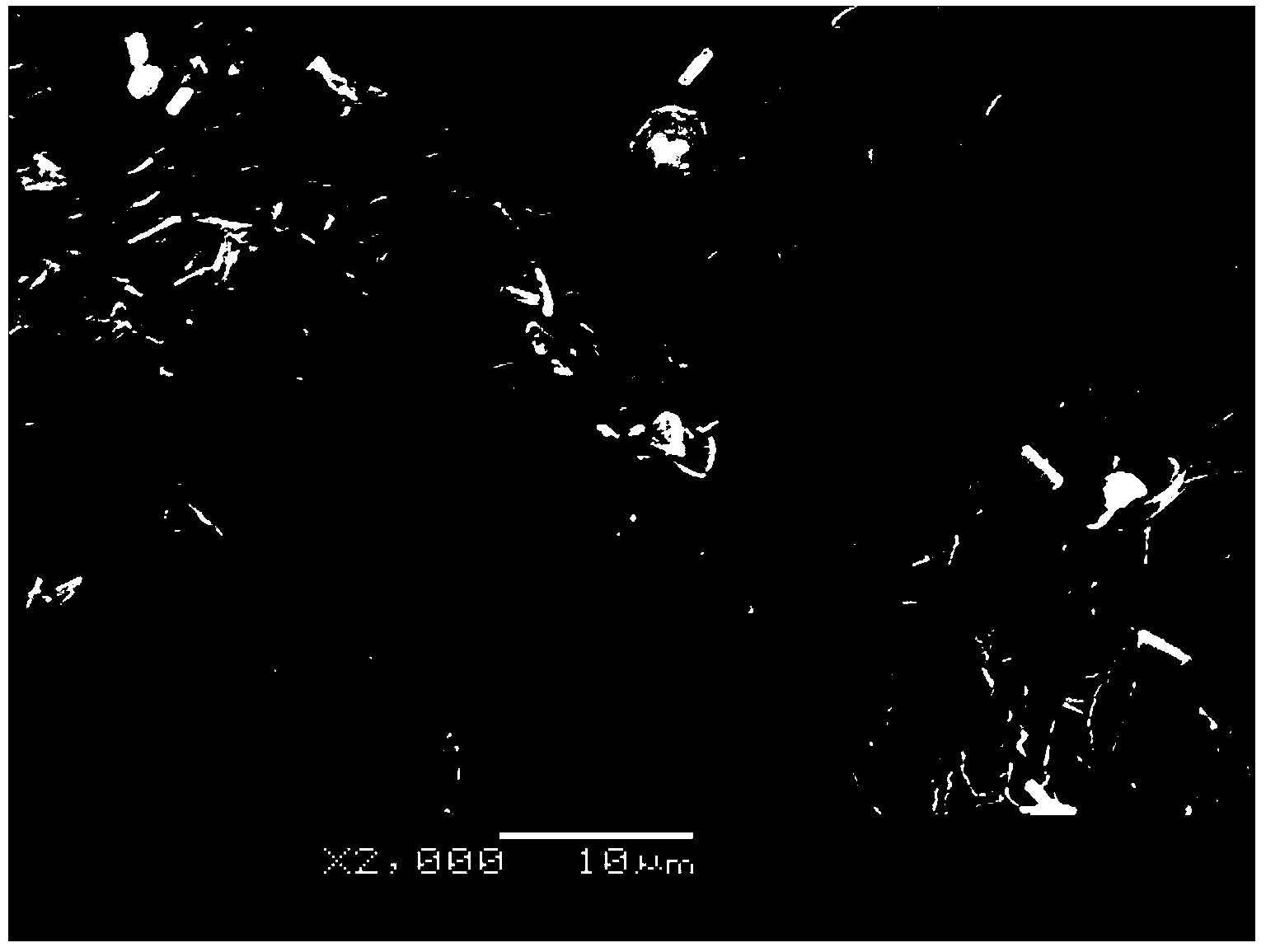

[0025] The third step is to centrifuge the suspension at high speed (10000rpm) to obtain a white precipitate. The precipitate was freeze-dried to obtain collagen microfibrils with a yield of about 22wt%. The microfibers are 3 μm in length and 0.5 μm in width.

Embodiment 2

[0027] The first step is to mix [Bmim]Cl with dimethyl sulfoxide ([Bmim]Cl concentration 80vol%) to make a treatment reagent.

[0028] Step 2: Add 0.5 g of dried pigskin powder into a reactor equipped with 50 ml of treatment agent, stir mechanically (500 rpm), and treat at 130° C. for 10 hours under nitrogen protection to prepare a suspension containing collagen microfibrils.

[0029] The third step is to centrifuge the suspension at high speed (10000rpm) to obtain a white precipitate. The precipitate was freeze-dried to obtain collagen microfibrils with a yield of about 27wt%. The microfibrils are 5 μm in length and 1 μm in width.

Embodiment 3

[0031] The first step is to mix [Amim]Cl with dimethyl sulfoxide ([Amim]Cl concentration 80vol%) to make a treatment reagent.

[0032] Step 2: Add 0.5 g of dried pigskin powder into a reactor containing 50 ml of treatment agent, stir mechanically (700 rpm), and treat at 130° C. for 12 hours under nitrogen protection to prepare a suspension containing collagen microfibrils.

[0033] The third step is to centrifuge the suspension at high speed (10000rpm) to obtain a white precipitate. The precipitate was freeze-dried to obtain collagen microfibrils with a yield of about 17wt%. The microfibers are 2 μm in length and 0.3 μm in width.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com