Method for preparing phosphatidyserine

A technology of phosphatidylserine and serine, which is applied in the direction of fermentation, can solve the problems of unsatisfactory conversion rate, high production cost, and excessive phosphatidic acid, and achieve the effect of short cycle, low cost and increased conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

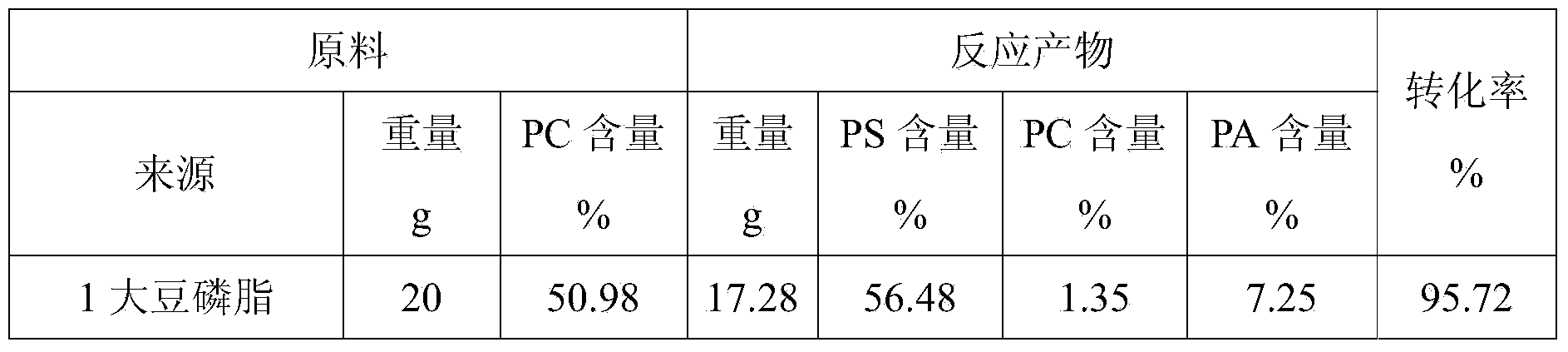

Embodiment 1

[0027] Add 20g of soybean phospholipid with a phosphatidylcholine content of 50.98% in the reaction tank, 40g of L-serine, Tween-800.02g, and 1.6g of calcium chloride. The buffer solution is sodium acetate-acetic acid system, pH value 5.5, buffer solution The addition amount is 100mL, the enzyme activity of phospholipase D is 5000U / g, and the addition amount is 100mg. Stir and keep the reaction temperature at 37°C, the reaction time is 8h, detect the conversion rate, centrifuge and filter, add 20mL of water to the filter residue after centrifugation and wash three times, and centrifugally filter the reaction crude product, add absolute ethanol 100mL to the reaction crude product, soak for 2h, stir for 1h, centrifuge Filtration, vacuum drying to obtain 17.28g PS content is 56.48% powder phospholipid.

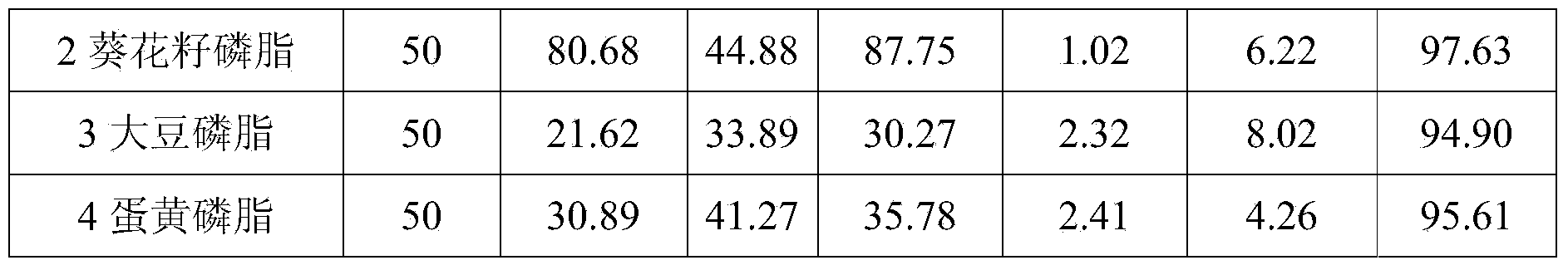

Embodiment 2

[0029] Add 50g of phosphatidylcholine content to the reaction tank and be 80.68% sunflower phospholipid, L-serine 150, Tween-800.2g, calcium chloride 6.0g, buffer solution selects sodium acetate-acetic acid system, pH value 5.3, buffer The addition amount of the solution is 400mL, the enzyme activity of phospholipase D is 5000U / g, and the addition amount is 400mg. Stir and keep the reaction temperature at 40°C, the reaction time is 10h, the conversion rate is detected, centrifugal filtration, after centrifugation, the filter residue is washed three times with 50mL of water, and the reaction crude product of centrifugal filtration is added to 400mL of absolute ethanol, soaked for 2h, stirred for 1h, centrifuged Filtration, vacuum drying to obtain 44.88g PS content is 87.75% powder phospholipid.

Embodiment 3

[0031] Adding 50g phosphatidylcholine content is 21.62% soybean lecithin in reaction tank, L-serine 100g, Tween-800.25g, calcium chloride 6.0g, buffer solution selects disodium hydrogen phosphate-phosphoric acid system, pH value 5.1, The added amount of buffer solution is 300mL, the activity of phospholipase D is 5000U / g, and the added amount is 220mg. Stir and keep the reaction temperature at 37°C, the reaction time is 10h, detect the conversion rate, centrifuge and filter, add 50mL water to the filter residue after centrifugation and wash three times, and centrifuge the reaction crude product, add absolute ethanol 300mL to the reaction crude product, soak for 2h, stir for 1h, centrifuge Filtration, vacuum drying to obtain 33.89g PS content is 30.27% powder phospholipid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com